Expansion tube assembly, oil well subsidy construction mechanism and construction method

An expansion tube and assembly technology, which is applied in the field of oil well subsidies, can solve the problems of reduced oil well productivity, adverse effects on oil well construction operation efficiency, and increased difficulty in downhole operations, and achieves the effect of reducing the impact.

Active Publication Date: 2010-08-25

华鼎鸿基石油工程技术(天津)有限公司

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, when performing oil extraction operations, it is necessary to use an oil production pump with a smaller outer diameter, which leads to a reduction in the production capacity of the oil well; similarly, when performing other operations, it is necessary to use a tool with a smaller outer diameter, which has a negative impact on the oil well. Adversely affect the efficiency of construction operations and increase the difficulty of downhole operations

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

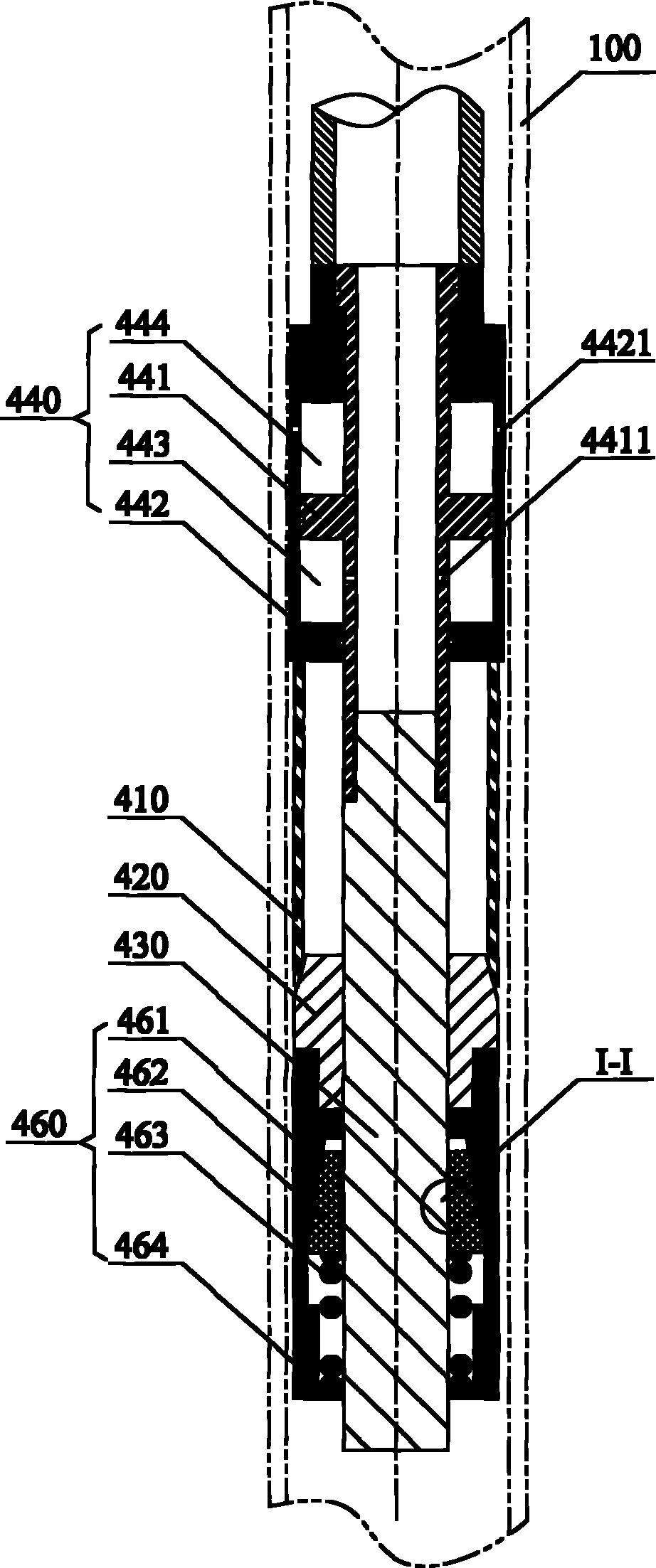

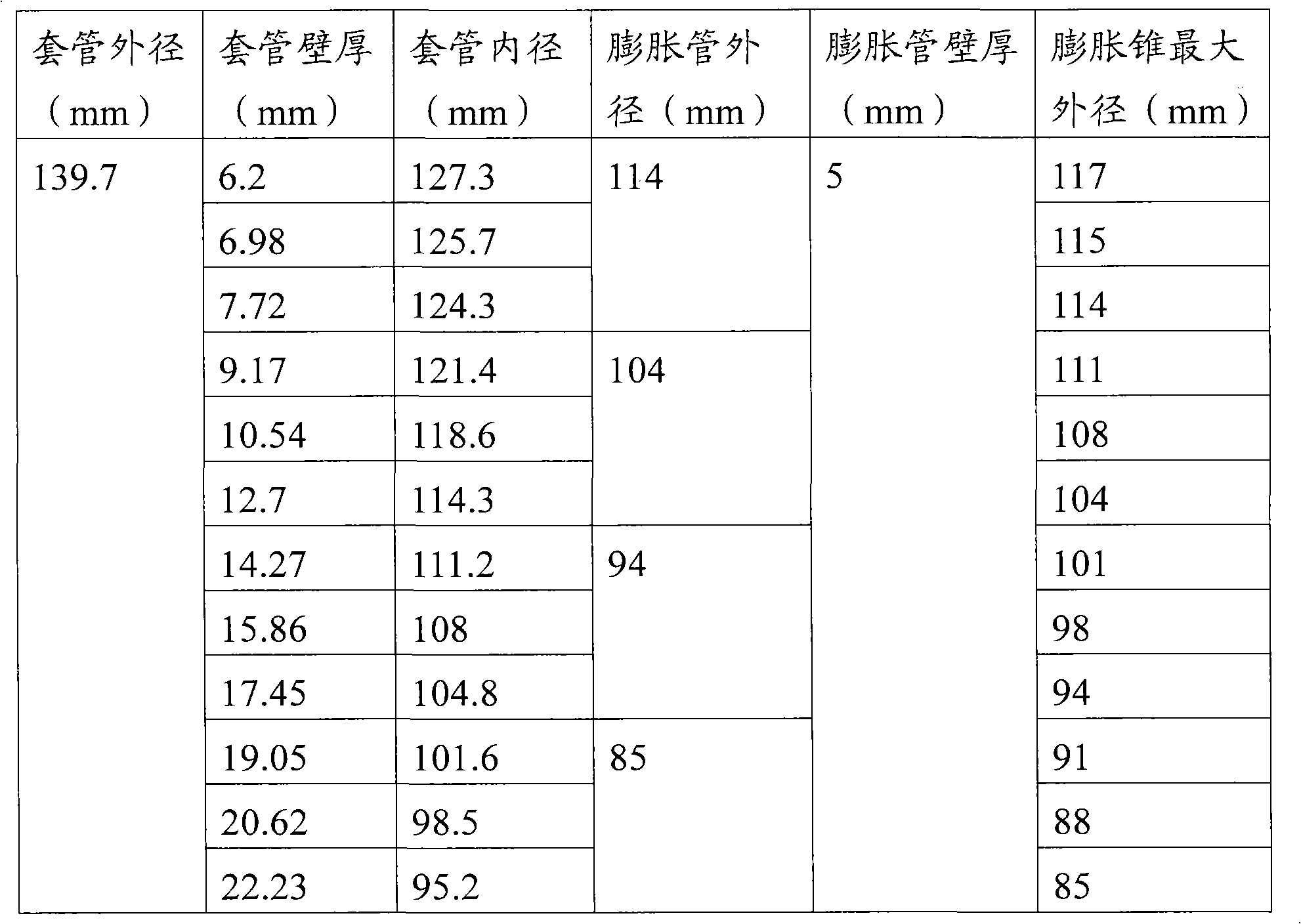

The invention discloses an expansion tube assembly, an oil well subsidy construction mechanism with the expansion tube assembly, and an oil well subsidy construction method. The disclosed expansion tube assembly comprises an expansion tube, an expansion cone, a central rod and a power cylinder, wherein the expansion cone is installed on the central rod; the power cylinder comprises a cylinder barrel and a piston; the piston rod of the piston can be respectively in sliding fit with the upper end part and the lower end part of the cylinder barrel; the piston body of the piston is installed on the piston rod and is matched with the inner wall surface of the cylinder barrel; a first pressure chamber and a second pressure chamber are formed in the cylinder barrel; the central rod is connected with the lower end of the piston rod; the expansion tube is sleeved outside the central rod and is positioned between the cylinder barrel and the expansion cone; the piston is provided with a pressurization channel; and the cylinder barrel is provided with a pressure relief vent. Compared with the existing expansion tube assembly, the expansion tube assembly disclosed by the invention does not have a pre-expansion part bearing high pressure, so that the expansion tube can have smaller thickness, the maximum diameter of the expansion cone is increased, the subsidy position has a larger drift diameter, and the influence of subsidy construction on an oil well is reduced.

Description

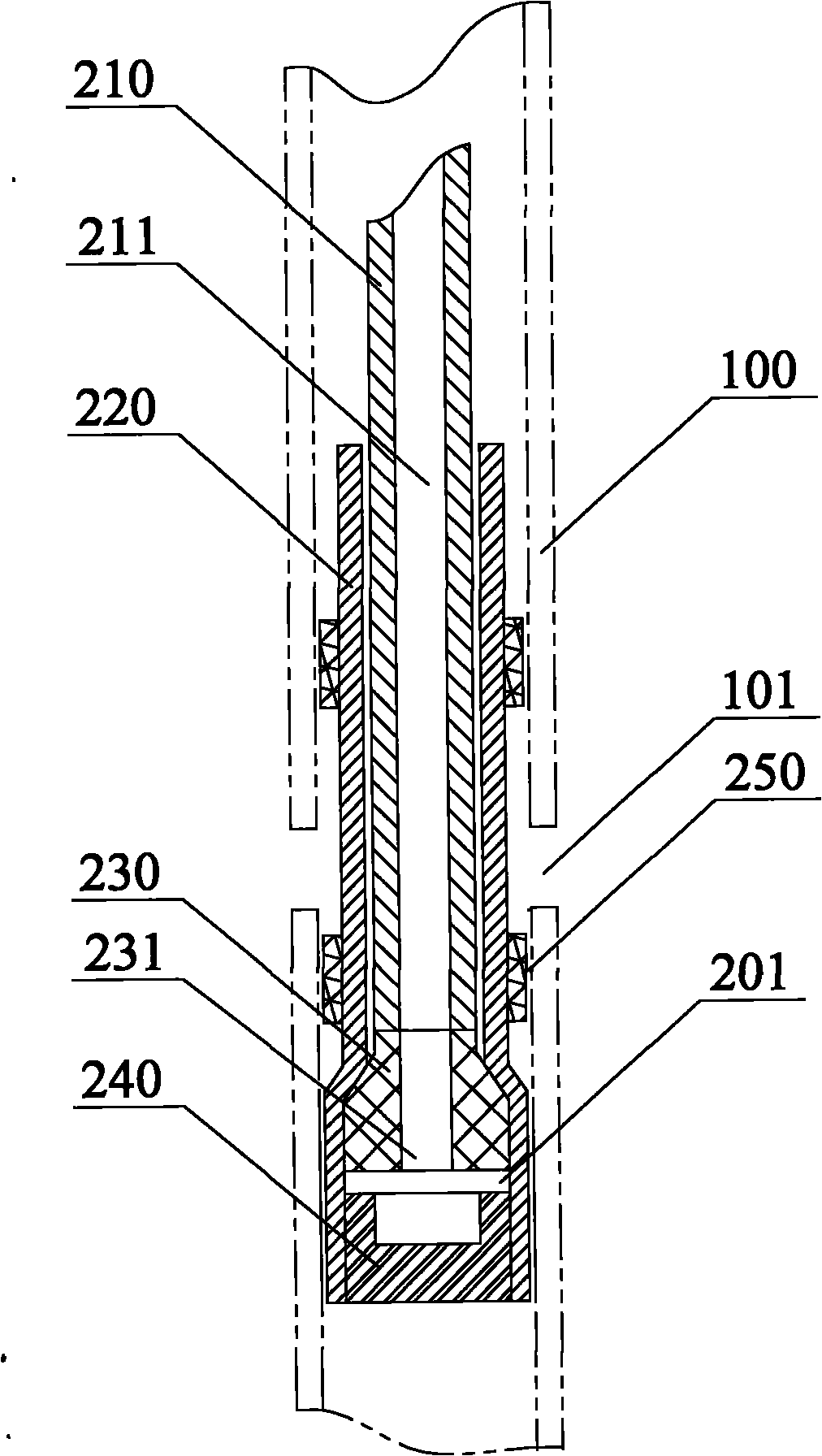

technical field The invention relates to an oil well subsidy technology, in particular to an expansion tube assembly, and also relates to an oil well subsidy construction mechanism with the expansion tube assembly and an oil well subsidy construction method using the expansion tube assembly. Background technique The oil well subsidy technology is a technology that uses the expansion pipe assembly to repair the damaged basic casing in the oil well to maintain the sealing performance of the oil well. Please refer to FIG. 1 and FIG. 2 , FIG. 1 is a schematic structural view of the expansion tube assembly in the prior art, and FIG. 2 is a schematic structural view of the expansion tube in the expansion tube assembly shown in FIG. 1 . The prior art oil well subsidy technology will be described below with reference to the accompanying drawings. The existing expansion tube assembly includes a central tube 210 , an expansion tube 220 , an expansion cone 230 , a plug 240 and a rubb...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B29/10

Inventor 谭延君

Owner 华鼎鸿基石油工程技术(天津)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com