Internal wear clearance measuring and calculating method of winding drum of winding machine

A wear gap and coiler technology, applied in the fields of machinery and iron and steel, can solve the problems of no reel wear measurement and the inability to know the size of the reel wear gap, so as to solve the waste of maintenance costs, reduce maintenance costs, and extend the replacement cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

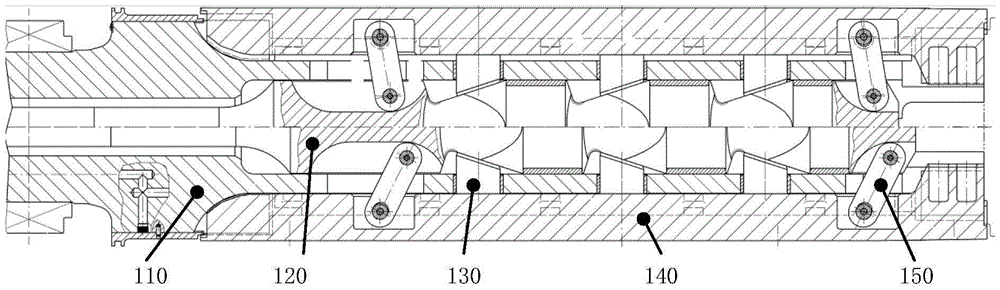

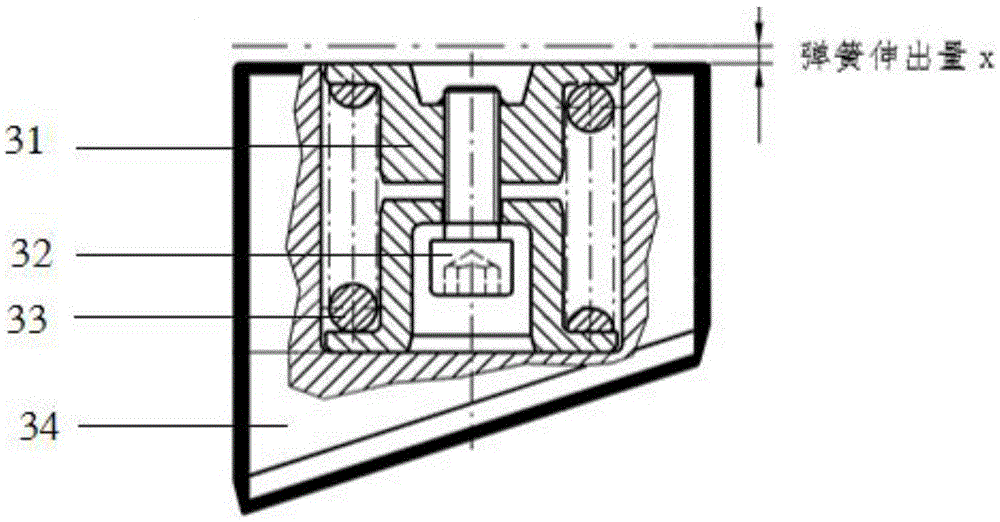

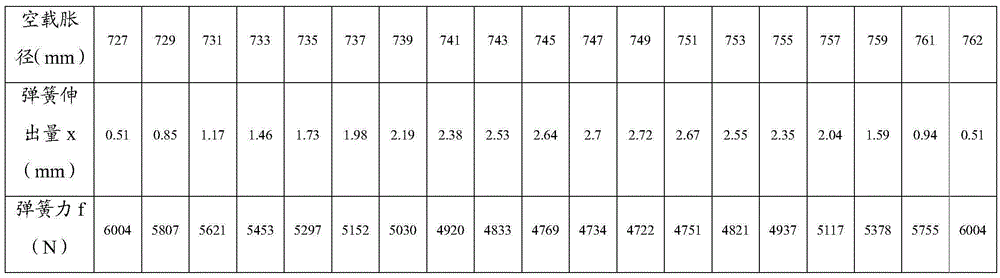

[0051] In order to measure and calculate the internal wear gap of the reel of the coiler, the embodiment of the present application first obtains the corresponding relationship between the no-load expansion diameter and the theoretical rigid expansion diameter of the reel and the maximum clearance allowed inside the reel.

[0052] 1. Corresponding relationship between no-load expansion diameter and theoretical rigid expansion diameter

[0053] In the specific implementation process, since the mandrel 120 of the reel and the fan-shaped plate 140 are connected by means of the connecting rod 150, the extension of the spring 33 of the wedge block 130 varies under different no-load expansion diameters, that is, no-load expansion. The corresponding curve of diameter and spring 33 extension is non-linear. By measuring and calculating the drawings, it is obtained that the no-load expansion diameter of the reel is from 727mm to 762mm corresponding to the extension of the spring 33 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com