Anchor drawplate type cable-beam anchorage structure for cable-stayed bridge

A cable beam anchoring and anchoring plate technology, applied in the field of bridge engineering, can solve the problems of reduced procurement and inspection costs, low fatigue strength, etc., and achieve the effects of reduced procurement and inspection costs, high fatigue strength, and reasonable structural form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

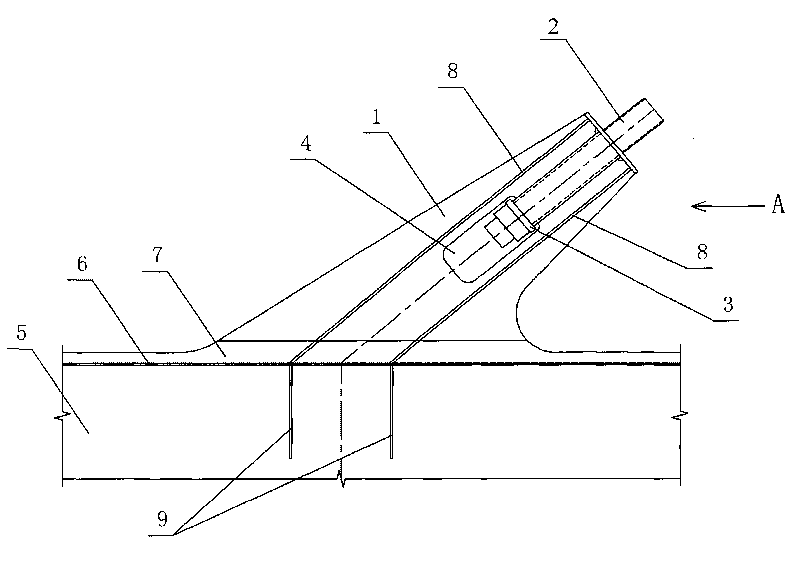

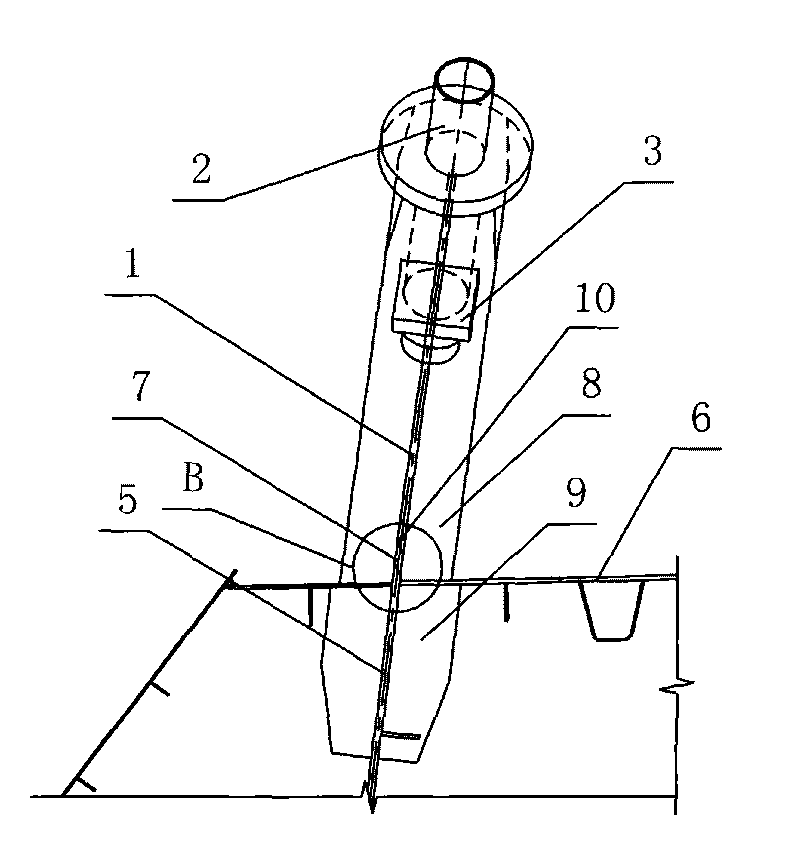

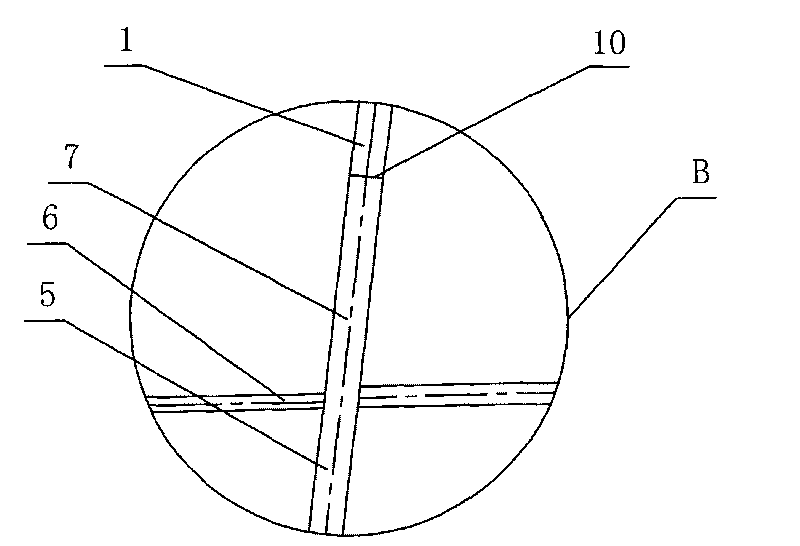

[0027] Such as Figure 1~3 Shown, is the present invention a kind of cable-stayed bridge anchor pull plate type cable girder anchorage structure, comprises steel girder and the anchor pull plate assembly that is arranged on the top surface of steel girder, anchor pull plate assembly comprises anchor pull plate 1, is used for The anchor pipe 2 with the stay cable and the anchor backing plate 3 arranged at the bottom of the anchor pipe 2 and installed vertically with the anchor pipe 2, the anchor stay plate 1 is selected according to the size of the cable force of the stay cable, and the anchor stay plate 1 is There is a counterbore-shaped groove 4 in the center of the top along the central axis. The size of the notch of the groove 4 should meet the space requirements for the hanging operation of the stay cable. The anchor pipe 2 is installed in the upper part of the groove 4. The outer wall of the pipe 2 and the inner wall of the groove 4 are connected by penetration welding, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com