Radiation crosslinking chloroprene rubber heat shrinkage material and preparation method thereof

A chloroprene rubber, radiation cross-linking technology, applied in other home appliances, applications, home appliances, etc., can solve the problems of low temperature resistance, oil resistance and heat aging resistance, and achieve good heat aging resistance and pipe performance Good, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of above-mentioned radiation cross-linked chloroprene rubber heat-shrinkable material comprises the following steps:

[0048] Step 1: Weigh 100 parts of polyolefin substrate, 5-20 parts of neoprene rubber, 5-20 parts of chlorinated polyethylene, 0.5-3 parts of antioxidant, 1-15 parts of plasticizer, color 1-5 parts of masterbatch, mix well at room temperature;

[0049] Step 2: After cooling and crushing the homogeneously mixed material in step 1, extrude the strands with a twin-screw extruder in the temperature range of 130°C-180°C, water-cool, air-dry, and pelletize;

[0050] Step 3: extruding the above-mentioned pellets into a tube at a temperature of 130°C-180°C;

[0051] Step 4: irradiate the above-mentioned pipes with gamma rays or electron accelerators, and the radiation dose is 80-200KGY;

[0052] Step 5: Then expand and stretch the above-mentioned tube to 0.5-3 times at a temperature of 100-200°C to form a heat-shrinkable tube.

[0053]...

preparation Embodiment 1

[0057] Take various components according to the table:

[0058] According to the above ratio, mix the above materials evenly in the internal mixer (the mixture is 20kg in total).

[0059] Then extrude the strands through a twin-screw extruder at a temperature of 160°C, water-cool, air-dry, and pelletize.

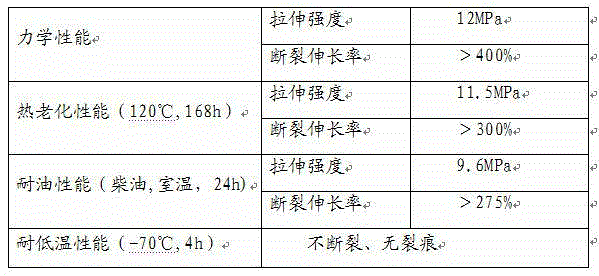

[0060] It is then extruded into a tube, irradiated by an electron accelerator at 100KGY, and then expanded twice to form a heat-shrinkable tube. The measurements are as follows:

[0061]

preparation Embodiment 2

[0063] Take various components according to the table:

[0064]

[0065] According to the above ratio, mix the above materials evenly in the internal mixer (the mixture is 20kg in total).

[0066] Then extrude the strands through a twin-screw extruder at a temperature of 130°C, water-cool, air-dry, and pelletize.

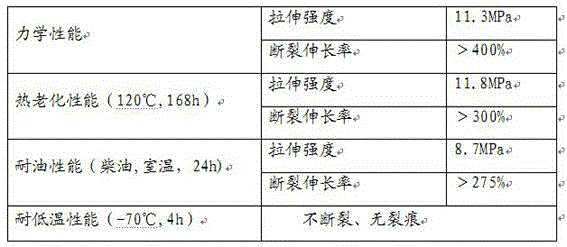

[0067] It is then extruded into a tube, irradiated by an electron accelerator at 120KGY, and then expanded twice to form a heat-shrinkable tube. The measurements are as follows:

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com