Hand-operated air pressure sample introduction method for microfluidic chips

A microfluidic chip and air pressure technology, applied in the field of analytical chemistry, can solve problems such as insufficient, poor controllability, and difficult on-site detection, and achieve the effect of simple equipment structure, high cost performance, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

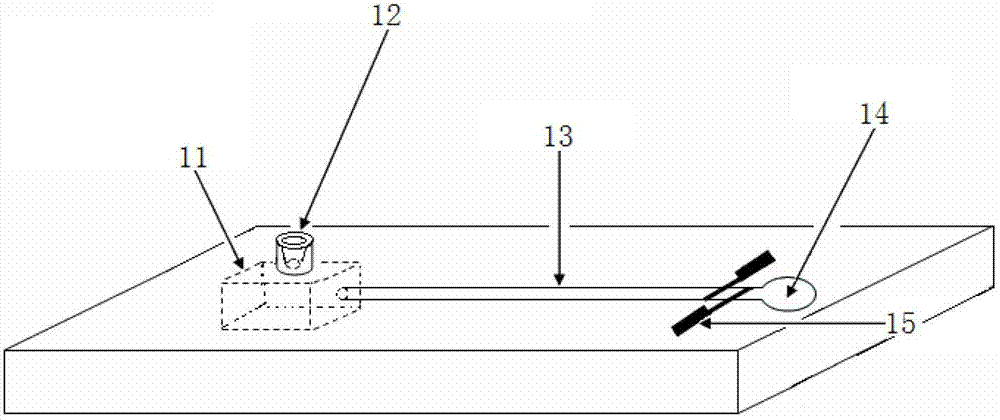

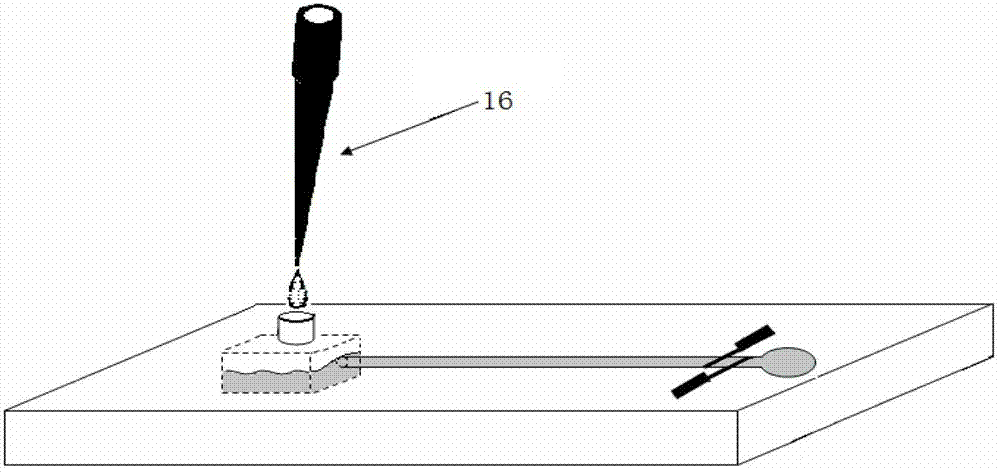

[0062] Such as image 3 As shown, the sample injection method of the present invention is specifically implemented as follows:

[0063] 1. In C 4 Steps for use on the microfluidic chip:

[0064] ① if image 3 Use a pipette to drop various trace liquids required for the reaction through the sample injection 12 (also a pressure port), and drop them into the built-in cavity (ie, pre-reaction and mixing area) on the microfluidic chip card. Perform a pre-stay reaction, wait for pressurization at any time, and move to the direction of the waste liquid outlet.

[0065] ② if Figure 4 , twitch the syringe plunger, use the outlet of the syringe joint to apply air pressure, insert it into the injection port 12 on the chip, and anastomose to form a seal. Push the piston to form an air pressure P. Under the action of P, the sample liquid in the cavity slowly moves to the right, as indicated by the arrow, passes through the detection electrode, and flows to the waste liquid outlet.

...

Embodiment 2

[0068] Due to the microfluidic chip manual air pressure sampling technology of the present invention, it can be widely used in combination with various detection devices (detectors). Therefore, for specific operation and use, the sampling technique of the present invention is basically irrelevant to what kind of detector and detection device is used.

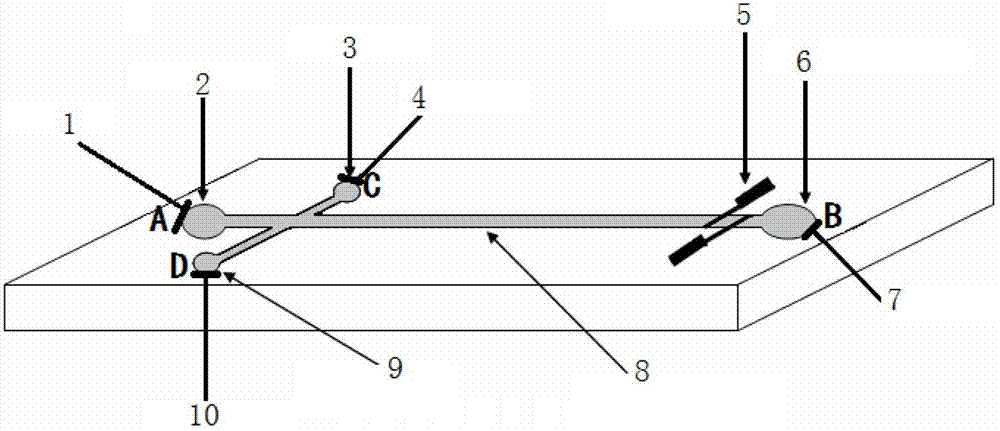

[0069] Such as Figure 5 , is an example of the application of the design principle of the present invention (manual air pressure to drive liquid flow) on the MCE (Microchip Capillary Electrophoresis, chip capillary electrophoresis) microfluidic chip. The usage steps are basically similar to the above 1.

[0070] Such as Figure 5, in the design of the chip card, the buffer driving electrode in the conventional MCE microfluidic chip is canceled, and one separation electrode 20 is set on the inner left wall of the buffer mixing area, and the other is set on the waste liquid outlet 23. During detection, a slightly excess buffer...

Embodiment 3

[0072] Using the microfluidic chip manual mixing simple pressure sampling method of the present invention, the K in the water sample has been successfully implemented + , Mg 2+ Ion separation from background buffer ethanesulfonic acid (MES)-histidine (His), and C 4 D detection.

[0073] The detection principle is to use background buffer ethanesulfonic acid (MES)-histidine (His) to separate and separate and detect K + , Mg 2+ Ions, driven by the air pressure of the injector, flow slowly (about 1mm / s) through such as figure 2 When the conductance detection electrode is 15, the measured continuous current change waveform features, and the K in the liquid sample is measured + , Mg 2+ The presence of characteristic conductance signals.

[0074] Device conditions for the detection test: MES:His ratio 1:0.9, pH value 4 D excitation signal is continuous sine wave 100Hz, voltage 5V, completed by one DG1022 general source signal generator. Such as figure 2 One piece of microf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com