Temperature-responsive fiber and method of preparing same

A technology of temperature response and fiber, which is applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of low temperature response material filling, limited temperature response capability, and difficult packaging of the latter, so as to expand the variety and application range , good stability and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In some embodiments, the preparation method of the temperature-responsive fiber specifically includes:

[0035] The porous fiber is immersed in the temperature-responsive material solution, then left to stand in a vacuum environment or normal pressure environment, and then taken out and dried, so that the temperature-responsive material is encapsulated in the mesopores of the porous fiber, and then the temperature-responsive fiber is obtained.

[0036] Among them, the choice of solvent in the temperature-responsive material solution depends on the types of porous fibers and temperature-responsive materials. The solvents used in existing experiments are mainly common solvents such as water, ethanol, methanol, tert-butanol, and dimethyl sulfoxide; for low-viscosity In order to ensure the filling efficiency, temperature responsive materials are often filled directly with saturated solution or molten state. For high viscosity temperature responsive materials, glycerin, ethyl...

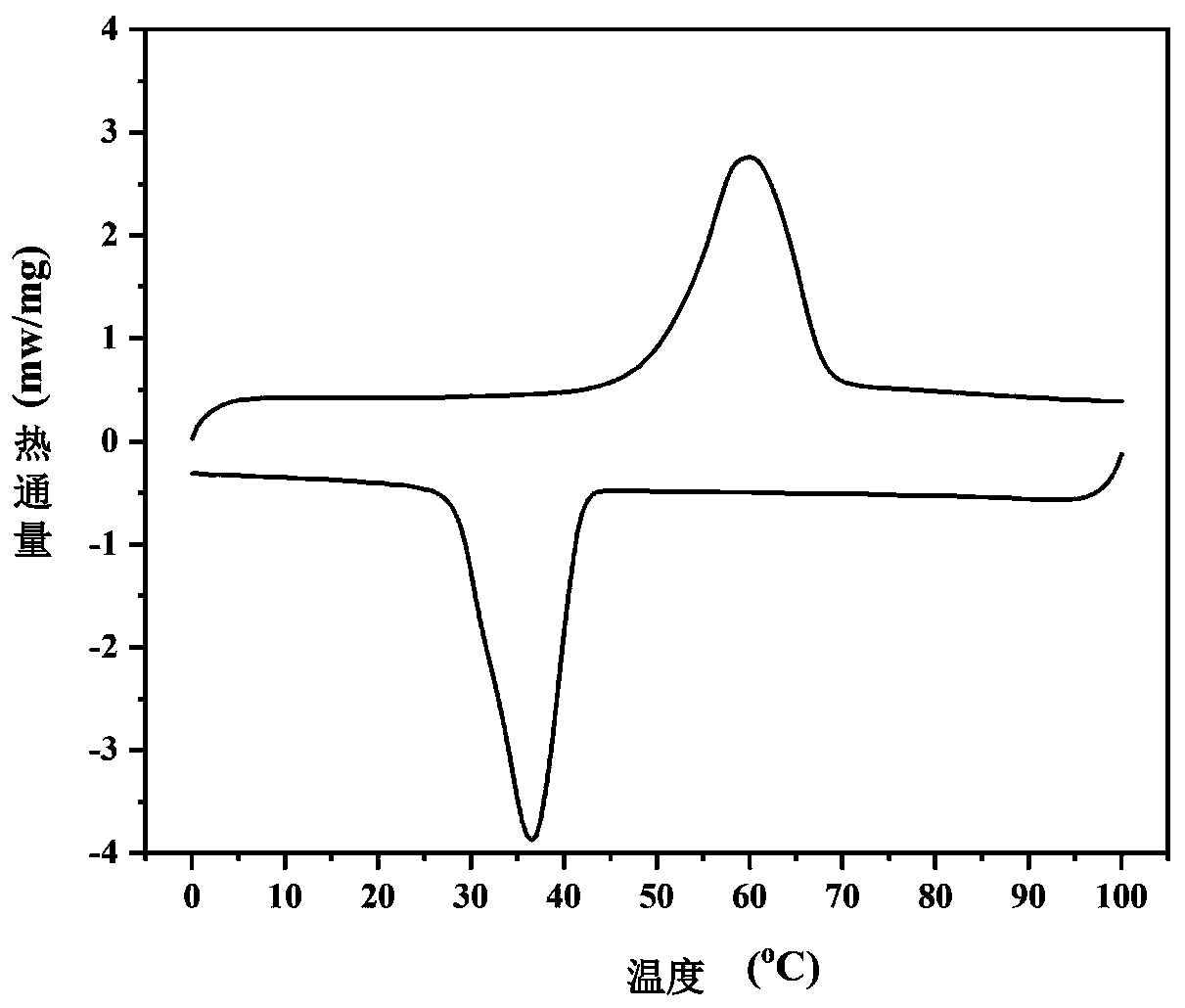

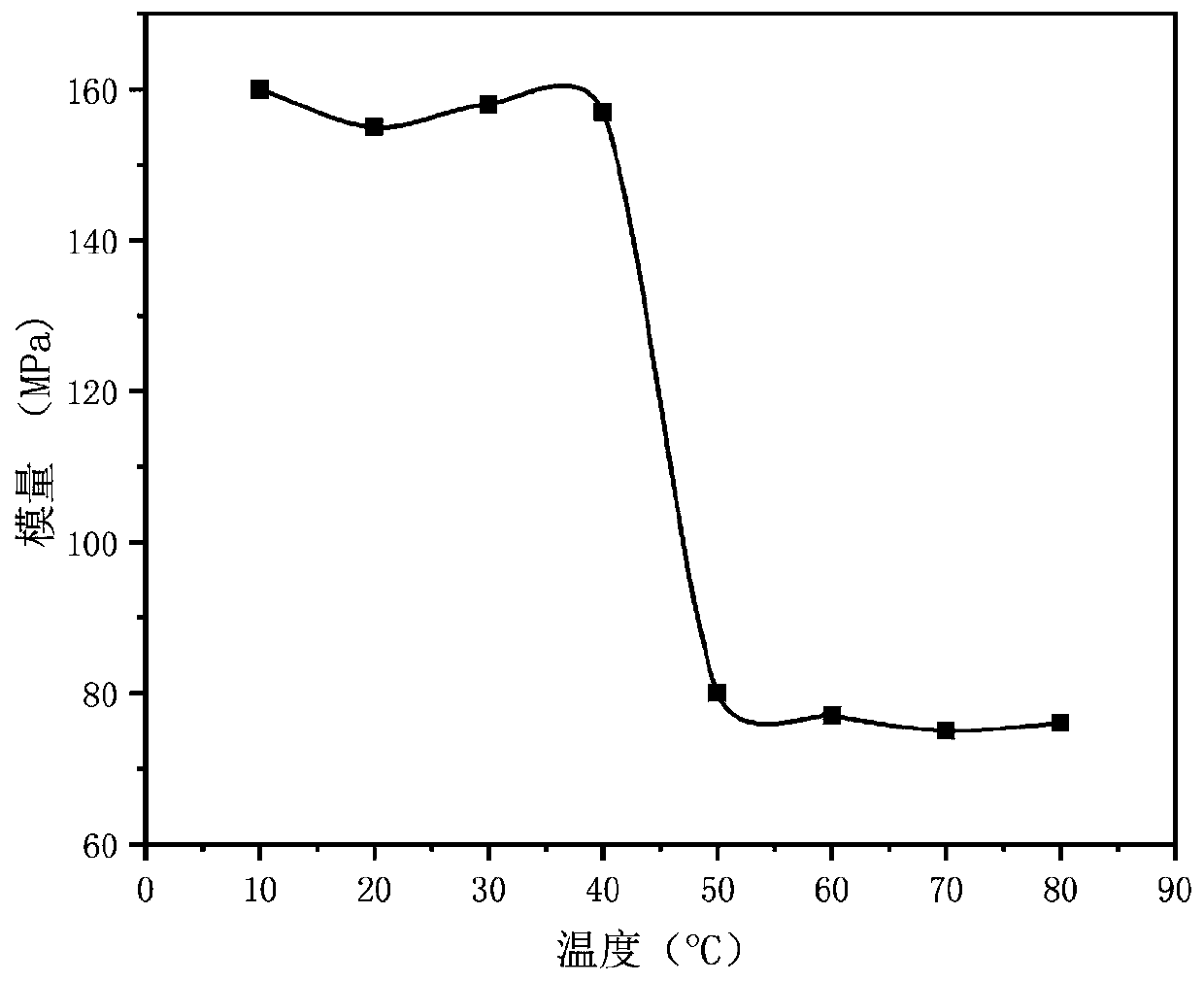

Embodiment 1

[0065] (1) Prepare cellulose wet fiber by wet spinning process (the wet fiber in the embodiment is the aforementioned solvent-containing fiber, the same below), and adopt supercritical drying technology to dry the cellulose wet fiber to obtain the cellulose porous fiber, The average pore size of cellulose porous fibers is 200nm, the pore size distribution is 15-500nm, and the porosity is 98%;

[0066] (2) Heating paraffin (heat-induced aggregation state change material) to 80°C to obtain liquid paraffin, impregnating the cellulose porous fiber in liquid paraffin, placing it in a vacuum oven, and standing it at 80°C under vacuum for 8 hours to obtain Composite fiber (the composite fiber in implementation is the temperature-responsive fiber formed by combining the former fiber and the temperature-responsive material, the same below);

[0067] (3) Take out the composite fiber, use absorbent paper to absorb excess liquid paraffin on the surface of the composite fiber, place the co...

Embodiment 2

[0069] (1) Prepare polyamic acid wet fiber by wet spinning process, soak polyamic acid wet fiber with acetic anhydride pyridine mixed solution to obtain polyimide wet fiber, and use supercritical drying technology to dry cellulose wet fiber to obtain Porous polyimide fiber, the average pore size of polyimide porous fiber is 30nm, the pore size distribution is 10-90nm, and the porosity is 95%;

[0070] (2) Dissolving PMMA (polymethyl methacrylate) in DMSO (dimethyl sulfoxide) to obtain a PMMA solution, immersing the cellulose porous fiber in the PMMA solution to obtain a composite fiber;

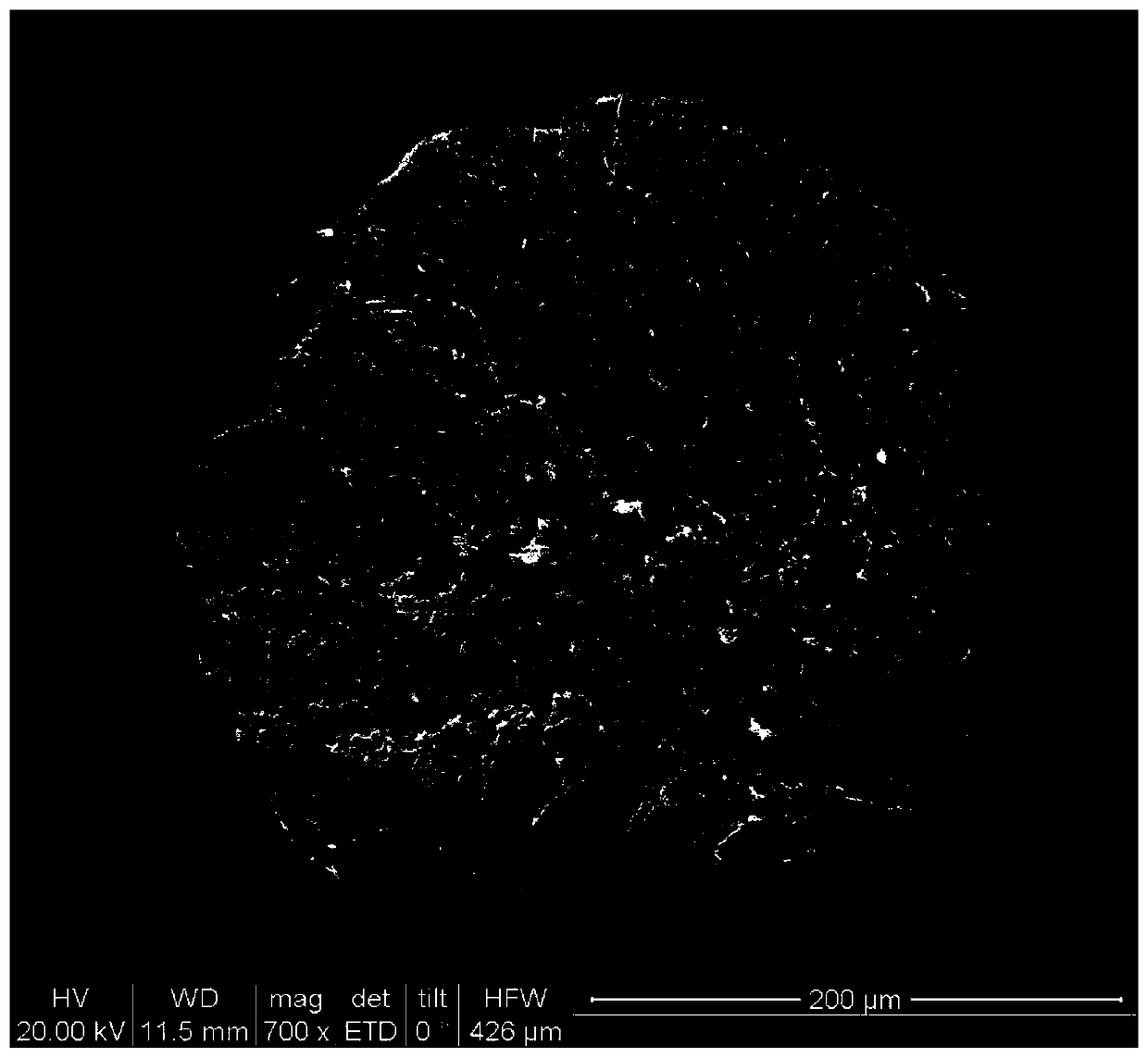

[0071] (3) Take out the composite fiber, use absorbent paper to absorb excess PMMA solution on the surface of the composite fiber, place the composite fiber in an oven at 80°C for shaping and drying, and obtain a temperature-responsive mechanical change fiber. Figure 4 A scanning electron microscope picture of the obtained temperature-responsive fibers is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com