Method using coating technology to prepare solution-method phenolic aldehyde prepreg

A technology for preparing solutions and prepregs, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc. High efficiency, excellent performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

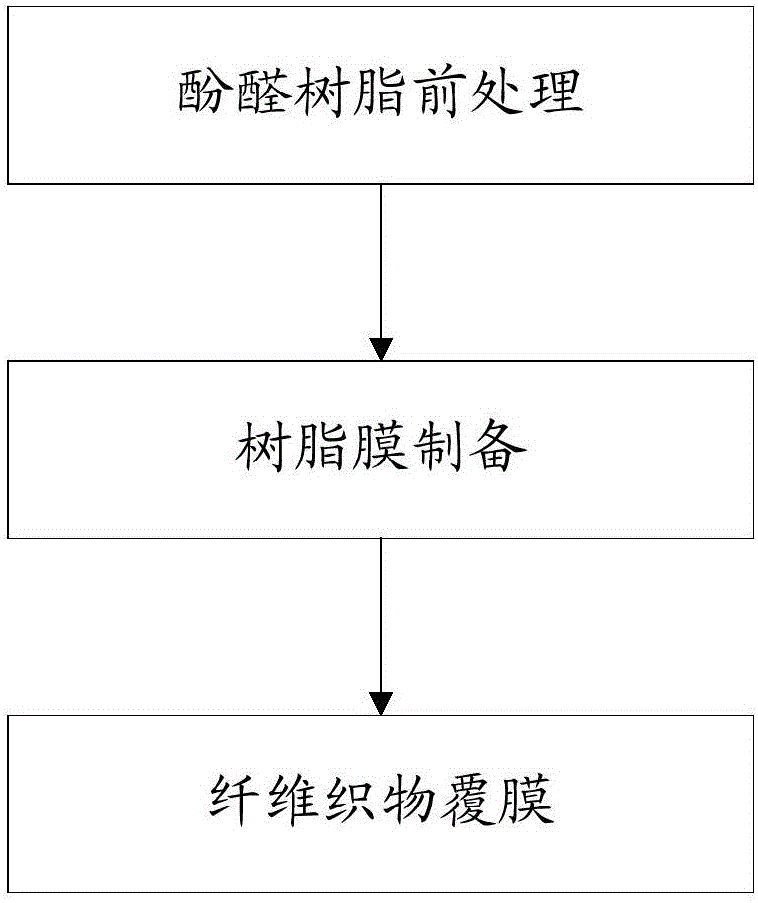

Method used

Image

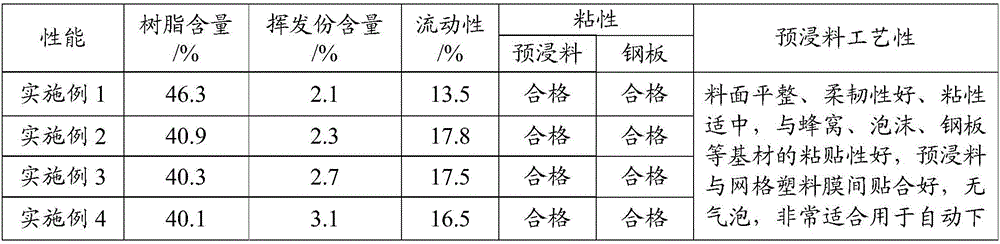

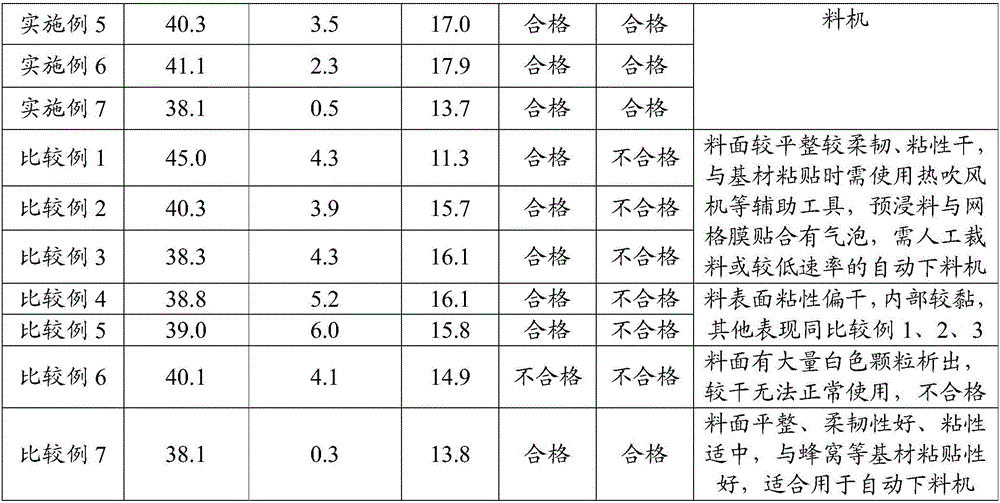

Examples

Embodiment 1

[0045] A glass fiber phenolic prepreg that can meet the requirements of BMS8-226Type I is prepared, the resin content is 46±3%, the volatile matter content is lower than 3.7%, and the fluidity is 14±5%.

[0046] According to the technical index requirements of BMS8-226, alkali-free glass fiber cloth with the same specification as 120 should be used, and its surface weight specification is 106±6g / m 2 . In the example of the present invention, four satin-type alkali-free glass fiber cloths of EW110C-120 are selected.

[0047] Phenolic resin solution The solution of barium hydroxide catalyzed phenolic resin and industrial alcohol modified by polyvinyl butyral (PVB) toughening, bromine-antimony mixed additive flame retardant and nano-silica thickening was selected as the research resin matrix, wherein the phenolic formaldehyde-phenol ratio is 1.8.

[0048] The steps of preparing the solution method prepreg by using the above-mentioned glass fiber cloth and phenolic resin solutio...

Embodiment 2

[0056] A glass fiber phenolic prepreg that can meet the requirements of BMS8-226Type II is prepared, the resin content is 41±3%, the volatile matter content is lower than 2.7%, and the fluidity is 18±4%.

[0057] According to the technical index requirements of BMS8-226, alkali-free glass fiber cloth with the same specification as 1581 should be used, and its surface weight specification is 295±10g / m 2 . In the example of the present invention, eight pieces of EW250F-120 three-flying satin-type alkali-free glass fiber cloth are selected.

[0058] Phenolic resin solution The solution of barium hydroxide catalyzed phenolic resin and industrial alcohol modified by polyvinyl butyral (PVB) toughening, bromine-antimony mixed additive flame retardant and nano-silica thickening was selected as the research resin matrix, wherein the phenolic formaldehyde-phenol ratio is 1.8.

[0059] The steps of preparing the solution method prepreg by using the above-mentioned glass fiber cloth and...

Embodiment 3

[0067] A glass fiber phenolic prepreg is prepared, the resin content is 38±3%, the volatile matter content is lower than 3.7%, and the fluidity is 14±4%.

[0068] The selected surface weight specification is 200±10g / m 2 plain fiberglass cloth. In the example of the present invention, the glass fiber cloth of EW200-90 is selected.

[0069] Phenolic resin solution The solution of barium hydroxide catalyzed phenolic resin and industrial alcohol modified by polyvinyl butyral (PVB) toughening, bromine-antimony mixed additive flame retardant and nano-silica thickening was selected as the research resin matrix, wherein the phenolic formaldehyde-phenol ratio is 1.6.

[0070] The steps of preparing the solution method prepreg by using the above-mentioned glass fiber cloth and phenolic resin solution through glue coating technology are as follows:

[0071] 1) Pour 100L phenolic resin solution into a closed reaction kettle, and vacuumize the reaction kettle under a low-speed stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com