Silicon carbide ceramic upper pressure head of high-temperature bending resistance testing machine, preparation method thereof and die

A technology of silicon carbide ceramics and testing machines, which is applied in the direction of molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of large machining allowance, large size, large shrinkage, etc., and achieve improved operation mode, strong practicability, and simple improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

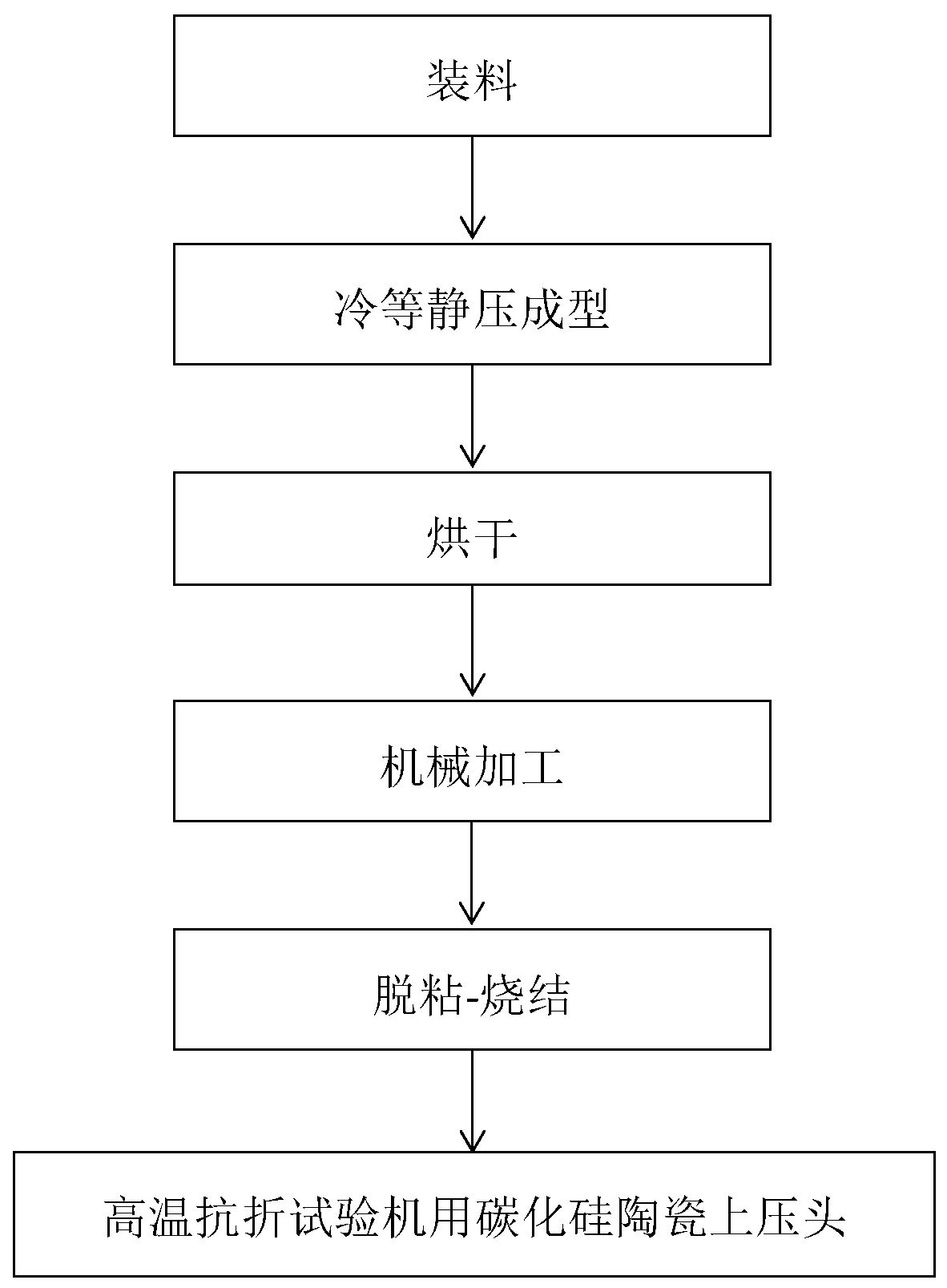

[0064] In the present invention, the upper pressure head of silicon carbide ceramics for high-temperature flexural testing machine and the preparation method thereof, the specific process steps are as follows:

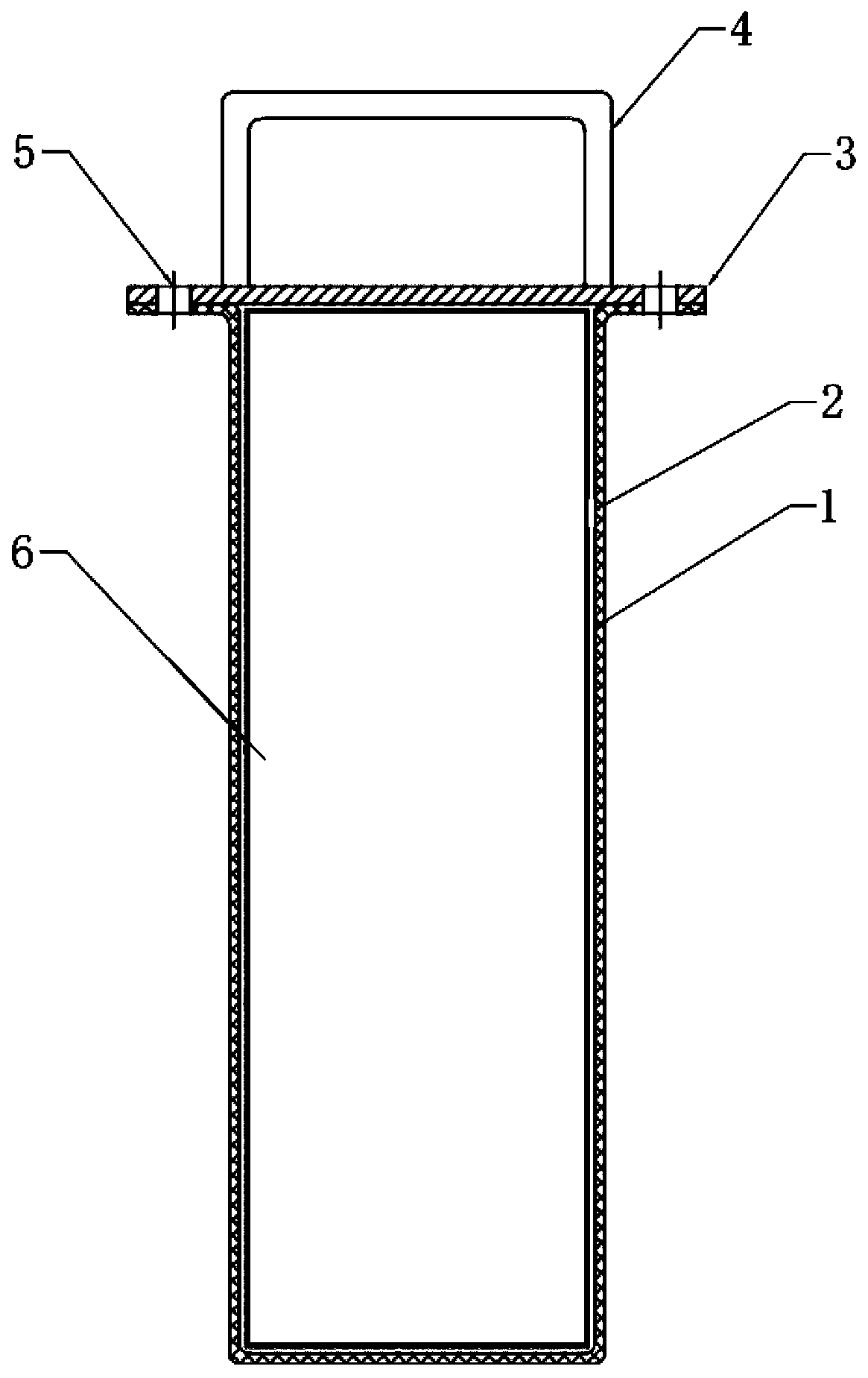

[0065] A: Molding: Put the inner mold cover tightly into the outer mold of aluminum alloy (the thickness of the inner / outer mold cover is 0.20mm, the inner diameter is 110mm, and the height is 700mm), and the upper cover plate (thickness 5mm, material 304 stainless steel). 8mm holes are evenly arranged on the outer wall of the aluminum alloy outer mold, and the distribution density is 5% of the outer peripheral area of the mold main body. Put the silicon carbide spray granulation powder into the inner mold sleeve, solid and full, then use a heat sealer to seal it, and put the whole mold into a cold isostatic press for direct compression;

[0066] B: Drying: put the shaped blank into an oven for drying;

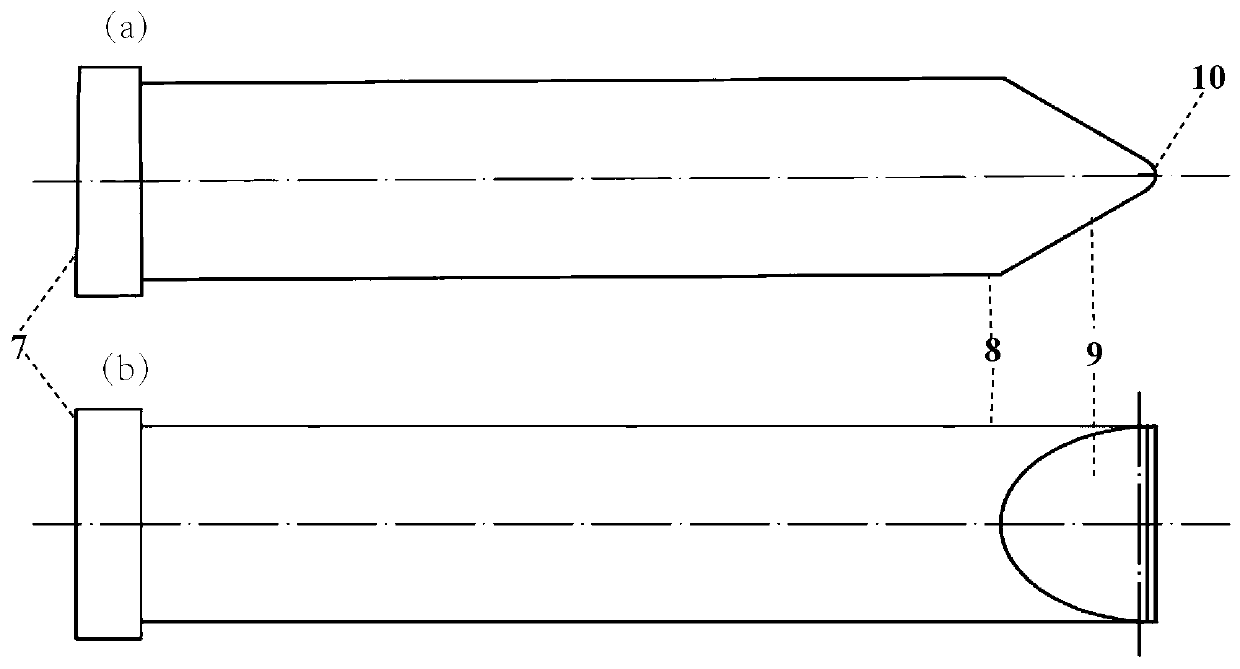

[0067] C: Biscuit processing: use CNC machine tools to mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com