Application of 1,1,2,2-tetraphenylethylene glycol used as RAFT polymerization initiator

A technology of tetraphenylethylene glycol and polymerization initiator, applied in the field of compound 1, can solve problems such as no TPED initiator, and achieve the effect of widening the range of types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Add monomers (MMA or St), TPED, and CPDN into a 2mL ampoule according to a preset molar ratio. Argon was bubbled to exhaust oxygen for 20 minutes, and then the tube was melted and sealed. Place the ampoule in an oil bath at a pre-set temperature to react. After the predetermined polymerization time, take out the reaction tube and immediately put it in an ice-water bath, open the seal, dissolve the polymer with a small amount of tetrahydrofuran, pour a large amount (about 300 mL) of methanol or petroleum ether (precipitate styrene with methanol, methacrylate The monomer was precipitated with petroleum ether), and the polymer was precipitated, filtered with suction, vacuum-dried to constant weight at room temperature, weighed, and the conversion rate was calculated.

[0029] In chain extension, CPDN is replaced by polymer, and other operations are similar.

Embodiment 2

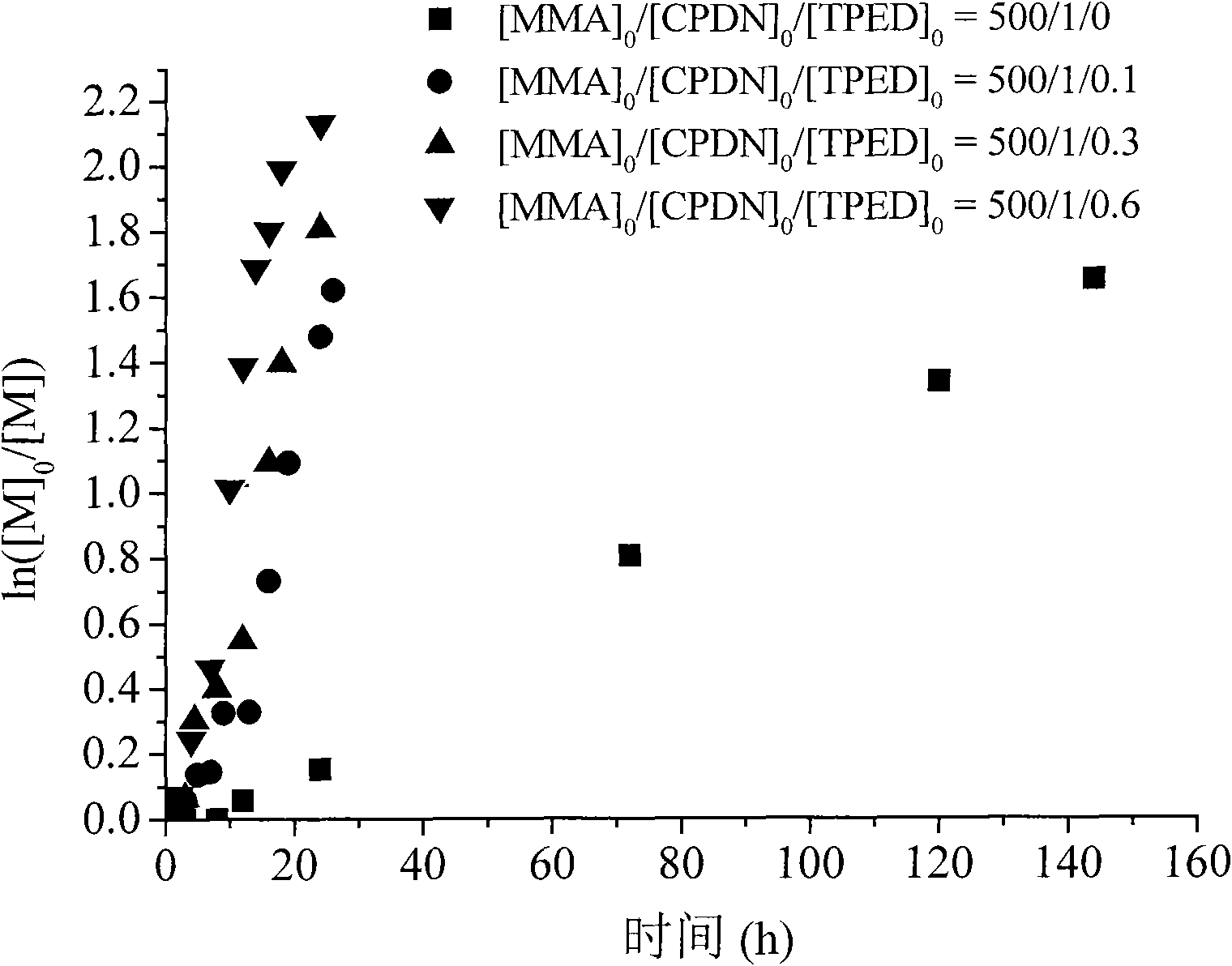

[0030] Embodiment two, research under different TPED concentration, the polymerization rate of the RAFT polymerization of methyl methacrylate (MMA), when investigating TPED as RAFT polymerization initiator, the influence of its concentration on polymerization reaction, in order to facilitate comparison, there is no TPED simultaneously RAFT aggregation under MMA. The result is as figure 1 , figure 2 shown;

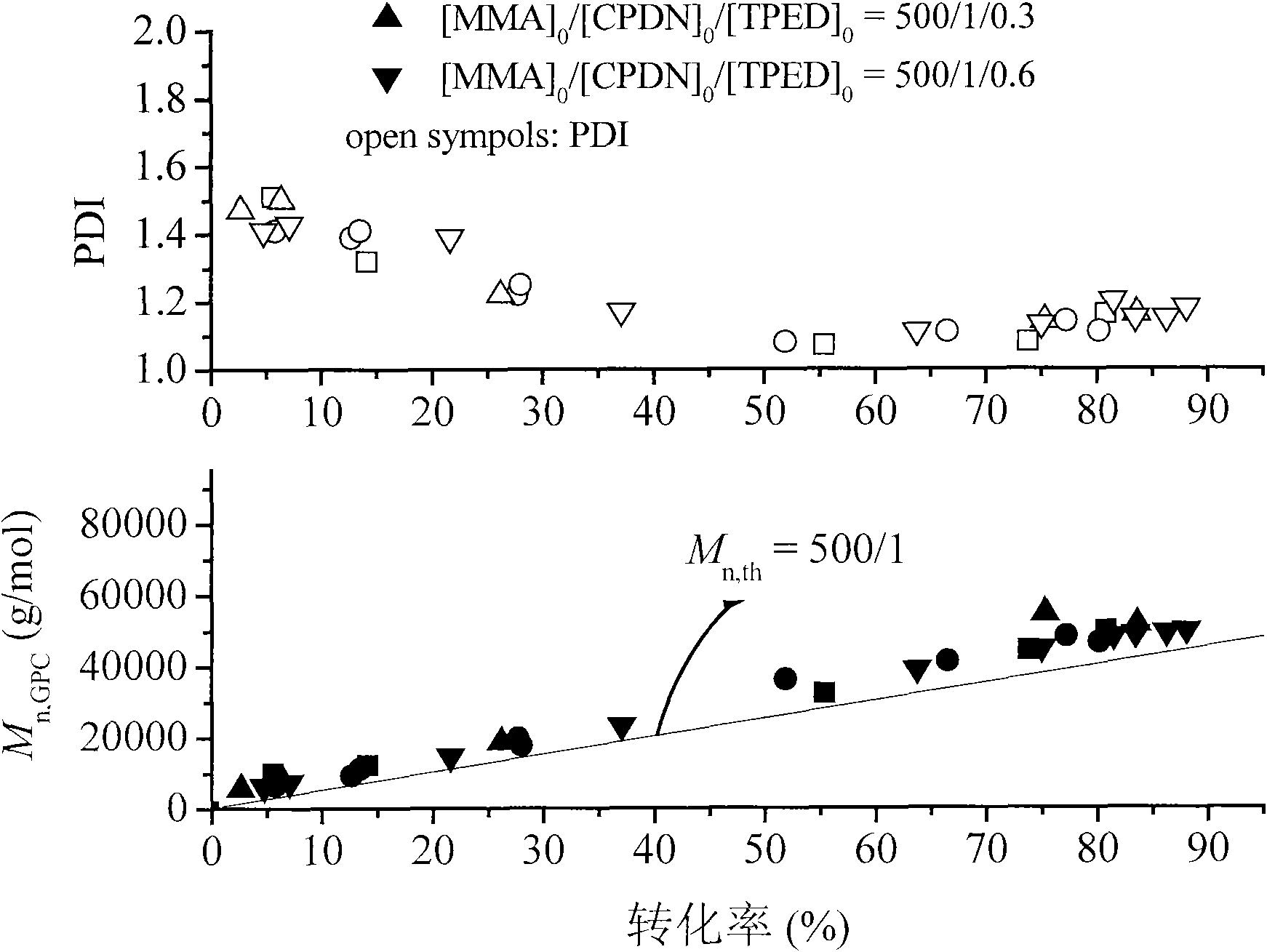

[0031] Depend on figure 1 It can be seen that without adding TPED, the polymerization rate is slow, after adding TPED, the polymerization rate is significantly improved, but when the molar ratio of TPED to MMA is increased from 500:0.1 to 500:0.6, the polymerization rate slightly increased; the number-average molecular weight of the polymer increases with the increase in monomer conversion (e.g. figure 2 shown), which is closer to the theoretical number average molecular weight, and the molecular weight distribution of the polymer is narrower. These results show tha...

Embodiment 3

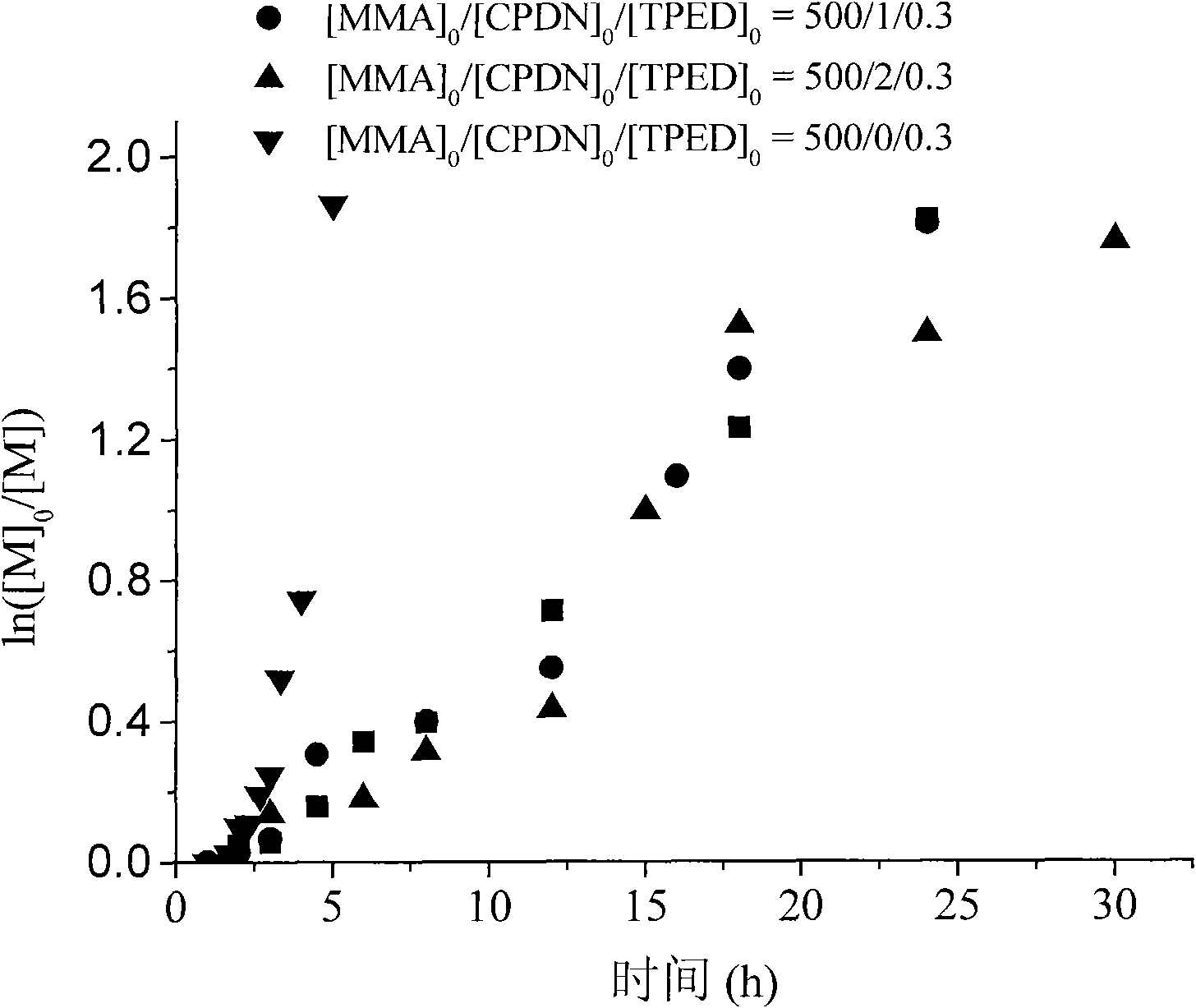

[0032] Embodiment three, investigate with TPED as initiator, the variation relation of polymerization rate and CPDN concentration, the result is as follows image 3 shown.

[0033] from image 3 It can be seen that at the same TPED concentration, the polymerization rate after adding CPDN is lower than that without CPDN, but the polymerization rate does not change much when the concentration of CPDN is changed within a certain range.

[0034] In order to verify whether this experimental phenomenon is related to the initiator TPED, we used AIBN as the initiator and compared it under the same experimental conditions. The result is as Figure 4 shown. It can be seen that with AIBN as the initiator, the polymerization rate has no obvious change in the same CPDN concentration range, indicating that the retardation phenomenon of RAFT polymerization has little to do with the initiator. Compare image 3 and Figure 4 It can also be seen that under the same conditions, the polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com