Drying oven for spraying

A technology of drying furnace and drying tunnel, which is applied in the direction of coating, incinerator, and device for coating liquid on the surface, etc., which can solve the problems of physical impact of workers, equipment overcapacity, and large equipment investment, etc., to reduce operating costs , energy saving, complete waste gas decomposition effect

Inactive Publication Date: 2010-09-15

ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

View PDF7 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The surface treatment of workpieces mostly adopts spraying technology, such as spray paint and plastic spraying. Most of the spraying agents need to be cured by heating after spraying, and the spraying agents will emit exhaust gas during the heating process. These exhaust gases include gaseous organic compounds. Such as benzene, xylene, etc., have strong toxicity. If they are not treated, they will not only have extremely bad effects on the health of workers, but also pollute the atmosphere. Therefore, waste gas treatment devices must be installed in the establishment of spraying production lines.

Exhaust gas treatment devices and spraying and drying devices currently on the market belong to different industries and are produced by different manufacturers, which results in excessive investment in equipment when put into production, and it is difficult to cooperate with equipment produced by different manufacturers during installation. It is easy to cause one of the equipment to overcapacity and waste

Exhaust gas treatment devices mostly use incineration to treat organic waste gas, which will generate a lot of heat during the incineration process. If the drying furnace is installed separately from the waste gas incinerator, a large amount of heat generated during the waste gas treatment process will be wasted.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0027] The difference from Example 1 is that the incineration temperature can reach 850 degrees Celsius.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

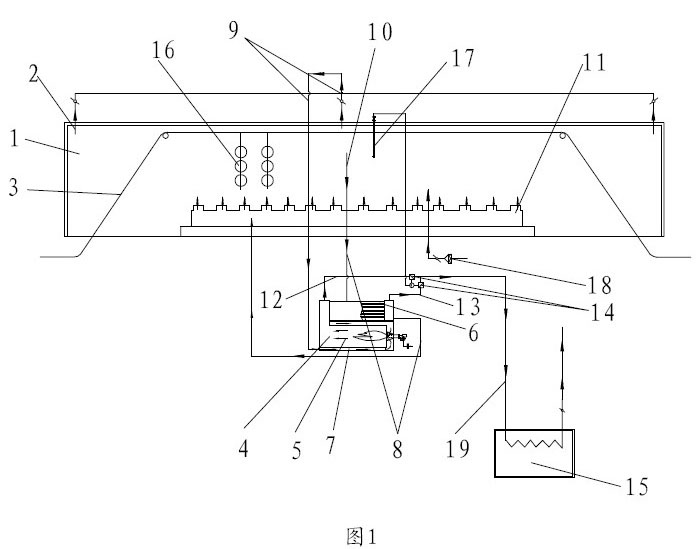

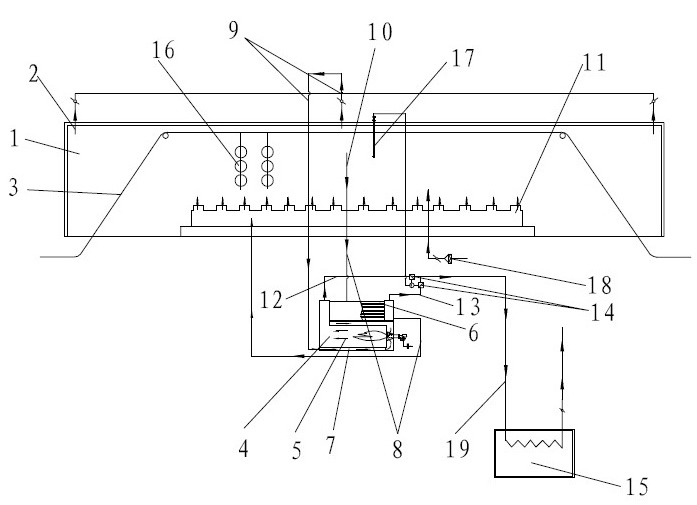

The invention relates to a drying oven for spraying, which comprises a drying passage and an exhaust gas incinerator. The drying passage is communicated with the exhaust gas incinerator through an exhaust gas pipeline and an air return pipeline; the wall of the drying passage is provided with an air return outlet, an exhaust gas inlet and an air return inlet; the exhaust gas inlet is communicated with the exhaust gas pipeline; the air return inlet and the air return outlet are communicated with the air return pipeline respectively; the exhaust gas incinerator comprises a heat exchanger which is communicated with the air return pipeline, and a preheater and an incineration chamber which are communicated with the exhaust gas pipeline; and the inlet of the incineration chamber is communicated with the outlet of the preheater, and the outlet of the incineration chamber is communicated with the inlet of the heat exchanger. The drying oven saves a large amount of equipment investment; an exhaust gas heat energy recovery and heat exchange process is introduced based on a hot blast stove with an original drying passage, and the heat energy generated by incinerated exhaust gas is fully utilized, so the heat energy recovery rate is high, energy resources required by the drying oven and the incinerator are greatly saved, and the operating cost is reduced; and the drying oven has the advantages of high exhaust gas treatment efficiency, high incineration temperature, complete exhaust gas decomposition and high purifying rate.

Description

technical field [0001] The invention relates to a spraying drying device, in particular to a spraying drying furnace integrating waste gas incineration and heat recovery devices. Background technique [0002] The surface treatment of workpieces mostly adopts spraying technology, such as spray paint and plastic spraying. Most of the spraying agents need to be cured by heating after spraying, and the spraying agents will emit exhaust gas during the heating process. These exhaust gases include gaseous organic compounds. Such as benzene, xylene, etc., have strong toxicity. If they are not treated, they will not only have extremely bad effects on the health of workers, but also pollute the atmosphere. Therefore, waste gas treatment devices must be installed in the establishment of spraying production lines. . Exhaust gas treatment devices and spraying and drying devices currently on the market belong to different industries and are produced by different manufacturers, which resu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05D3/02F23G7/06

CPCY02P70/10

Inventor 吕建立吴海珍

Owner ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com