Method for reducing generation of biogenic amine in soy sauce by changing fermentation temperature

A technology of fermentation temperature and biogenic amine, which is applied in the field of food processing, can solve the problems of poor quality, long time, and insufficient flavor of the product, and achieve the effects of easy operation, delayed enzyme activity, and improved raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

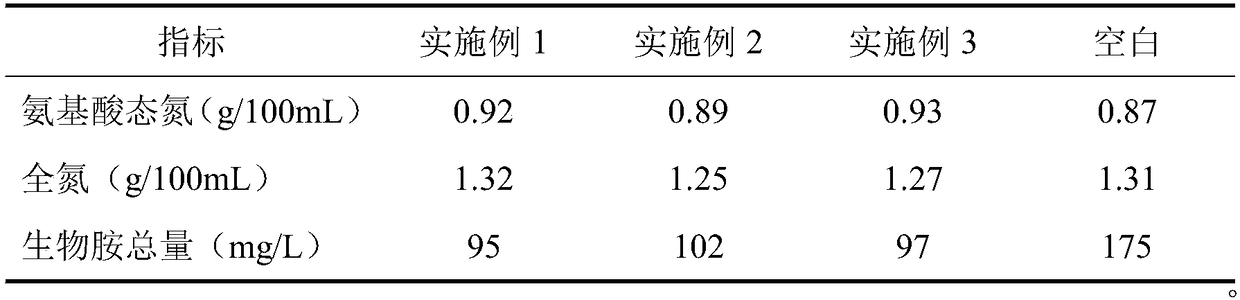

Embodiment 1

[0032] A method for reducing the production of biogenic amines in soy sauce by changing the fermentation temperature. The method reduces the production and accumulation of biogenic amines in the fermentation process of high-salt dilute soy sauce by changing the fermentation temperature after 30 days of fermentation.

[0033] Specifically, the high-salt dilute soy sauce fermentation is set at 30°C for 0-30 days, and then set at 18°C.

[0034] More specifically, the steps are as follows:

[0035] (1) Preparation of seed koji: Weigh an appropriate amount of bran into a conical flask, add water at a ratio of 1:1.1, stir evenly, and sterilize at 121°C for 20 minutes. On the aseptic operation table, pick 3 to 4 rings of activated Aspergillus oryzae spores from the rice koji juice medium and inoculate them into the seed koji medium. The inoculation amount is: 1 ring of spores per 20g of medium, and stir evenly , stack culture in a 30°C incubator. After cultivating for 15 hours, the...

Embodiment 2

[0043] A method for reducing the production of biogenic amines in soy sauce by changing the fermentation temperature. The method reduces the production and accumulation of biogenic amines in the fermentation process of high-salt dilute soy sauce by changing the fermentation temperature after 30 days of fermentation.

[0044] Specifically, the high-salt dilute soy sauce fermentation is set at 30°C for 0-30 days, and then at 19°C.

[0045] More specifically, the steps are as follows:

[0046] (1) Preparation of seed koji: Weigh an appropriate amount of bran into a conical flask, add water at a ratio of 1:1.1, stir evenly, and sterilize at 121°C for 20 minutes. On the aseptic operation table, pick 3 to 4 rings of activated Aspergillus oryzae spores from the rice koji juice medium and inoculate them into the seed koji medium. The inoculation amount is: 1 ring of spores per 20g of medium, and stir evenly , stack culture in a 30°C incubator. After cultivating for 15 hours, the koj...

Embodiment 3

[0054] A method for reducing the production of biogenic amines in soy sauce by changing the fermentation temperature. The method reduces the production and accumulation of biogenic amines in the fermentation process of high-salt dilute soy sauce by changing the fermentation temperature after 30 days of fermentation.

[0055] Specifically, the high-salt dilute soy sauce fermentation is set to 30°C for 0-30 days, and then set to 20°C.

[0056] More specifically, the steps are as follows:

[0057] (1) Preparation of seed koji: Weigh an appropriate amount of bran into a conical flask, add water at a ratio of 1:1.1, stir evenly, and sterilize at 121°C for 20 minutes. On the aseptic operation table, pick 3 to 4 rings of activated Aspergillus oryzae spores from the rice koji juice medium and inoculate them into the seed koji medium. The inoculation amount is: 1 ring of spores per 20g of medium, and stir evenly , stack culture in a 30°C incubator. After cultivating for 15 hours, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com