Thermoplastic polyimide microporous material and its preparation process

A technology of polyimide and microporous materials, applied in the field of preparation of microporous polymer materials, can solve the problems of poor comprehensive performance and complex process of microporous materials, and achieve good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

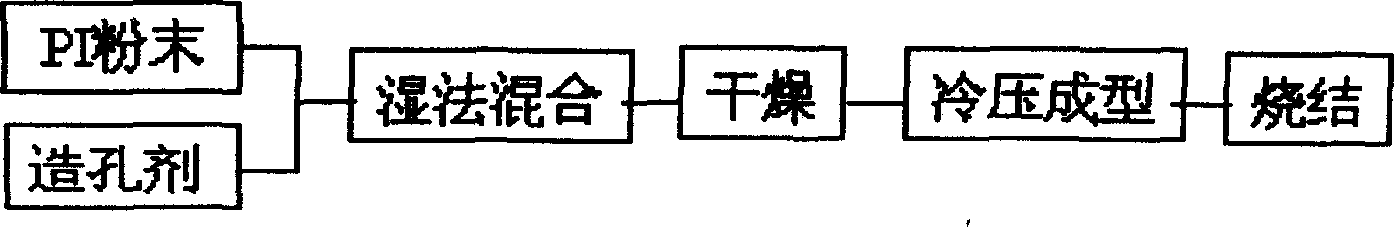

[0031] A kind of preparation method of thermoplastic polyimide microporous material, comprises the following processing steps: in 95g thermoplastic polyimide powder (Changzhou Guangcheng New Plastic Co., Ltd., GCPI TM Add polyethylene glycol (purity 99.5%, average molecular weight 20000) 5g in -M1 polyimide molding powder), the two adopt wet mixing, dry, the mixture is packed into the mould, after cold pressing with the pressure of 20MPa, Release the mold, and keep the pressed tablet at 160°C for 1 hour, and at 290°C for 4 hours. The porosity of the prepared microporous material is 16.4%, the bending performance is 40.9MPa, the friction coefficient is 0.06-0.07, and the volume wear rate is 6.61×10 -15 m 3 / (N·m). Its structure is as figure 1 shown.

Embodiment 2

[0033] A kind of preparation method of thermoplastic polyimide microporous material, comprises the following processing steps: in 90g thermoplastic polyimide powder (Changzhou Guangcheng New Plastic Co., Ltd., GCPI TM -M1 polyimide molding powder) was added citric acid (purity 99.5%) 10g, the two were mixed by wet method, dried, the mixture was put into the mold, after cold pressing with a pressure of 30MPa, demoulding, the tablet Incubate at 110°C for 1 hour and at 300°C for 2 hours. The porosity of the prepared microporous material is 21.3%, the bending performance is 42.3MPa, the friction coefficient is 0.06-0.065, and the volume wear rate is 4.85×10 -15 m 3 / (N·m).

Embodiment 3

[0035] A kind of preparation method of thermoplastic polyimide microporous material, comprises the following processing steps: in 80g thermoplastic polyimide powder (Changzhou Guangcheng New Plastic Co., Ltd., GCPI TM -M1 polyimide molding powder) was added 20g of methyl cellulose (purity 99.5%), the two were mixed by wet method, dried, the mixture was put into the mold, and after cold pressing with a pressure of 40MPa, demoulding , keep the pressed tablet at 180°C for 1 hour, and at 310°C for 1 hour. The porosity of the prepared microporous material is 16.4%, the bending performance is 35.6MPa, the friction coefficient is 0.07-0.08, and the volume wear rate is 2.81×10 -15 m 3 / (N·m).

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com