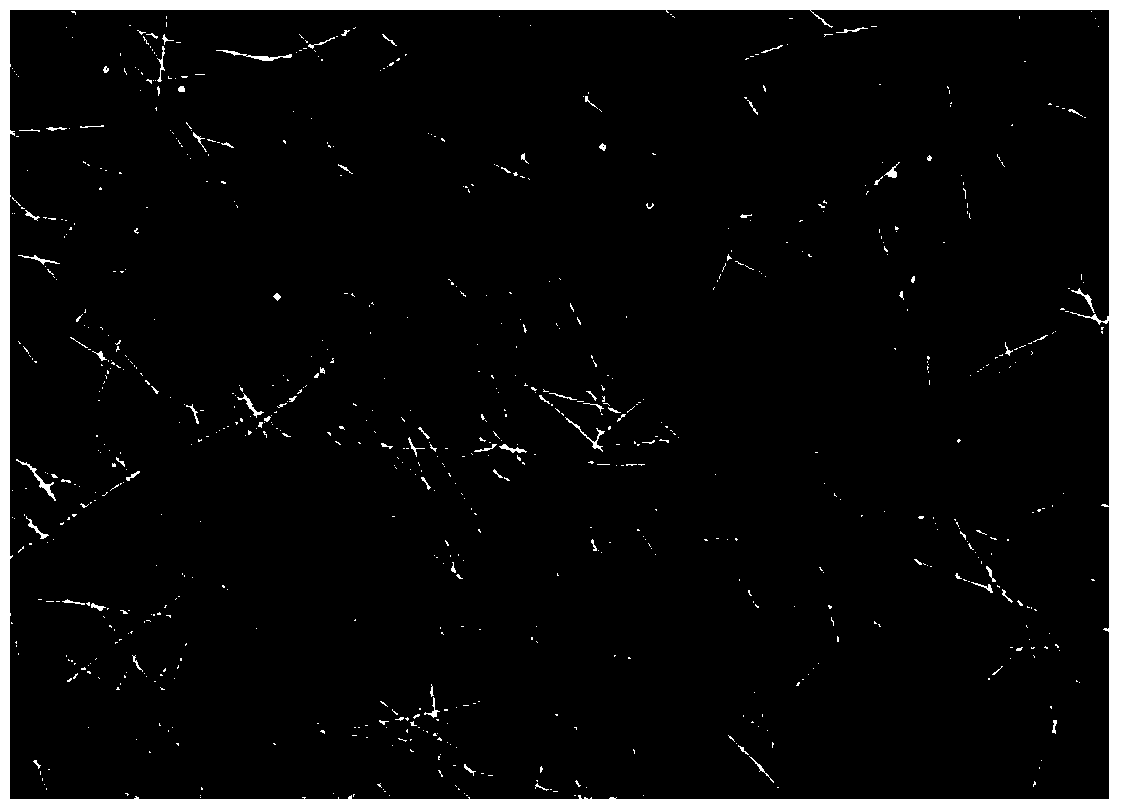

Multilayer structure composite transparent conducting thin film based on silver nanowires and preparation method thereof

A technology of transparent conductive film and multi-layer structure, which is applied to conductive layers on insulating carriers, cable/conductor manufacturing, circuits, etc., can solve the problems of poor conductivity and low conductivity of the final film, so as to reduce production costs and prevent oxidation. , the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of the composite transparent conductive film of the silver nanowire-based multilayer structure of the present embodiment comprises the following steps:

[0054] (1) At 25°C, a layer of AZO film with a thickness of 50nm is prepared on the PET substrate by magnetron sputtering, that is, the lower AZO conductive layer A. The sputtering conditions are: the sputtering gas is high-purity argon, and the sputtering gas is The pressure is 0.4Pa, and the aluminum oxide doped zinc oxide ceramic target is used in this embodiment, and the mass percentage of aluminum oxide is 2%;

[0055] (2) Prepare a silver nanowire suspension, and apply the silver nanowire suspension to the lower AZO conductive layer A by spin coating to form a silver nanowire conductive layer B, wherein the silver nanowire suspension is prepared Include the following steps:

[0056] (2-1) Magnetically stir 50ml of 0.15mol / L polyvinylpyrrolidone solution in ethylene glycol under heating at ...

Embodiment 2

[0068] The preparation method of the composite transparent conductive film of the silver nanowire-based multilayer structure of the present embodiment comprises the following steps:

[0069] (1) At 25°C, a layer of AZO film with a thickness of 300nm is prepared on the PET substrate by magnetron sputtering, that is, the lower AZO conductive layer A. The sputtering conditions are: the sputtering gas is high-purity argon, and the sputtering gas is The pressure is 0.5Pa, and the aluminum oxide doped zinc oxide ceramic target is used in this embodiment, and the mass percentage of aluminum oxide is 2%;

[0070] (2) Prepare a silver nanowire suspension, and apply the silver nanowire suspension to the lower AZO conductive layer A by spin coating to form a silver nanowire conductive layer B, wherein the silver nanowire suspension is prepared Include the following steps:

[0071] (2-1) Heat 50ml of 0.3mol / L polyvinylpyrrolidone in ethylene glycol under magnetic stirring at 180°C, and c...

Embodiment 3

[0079] The preparation method of the composite transparent conductive film of the silver nanowire-based multilayer structure of the present embodiment comprises the following steps:

[0080] (1) At a temperature of 150°C, a layer of AZO film with a thickness of 100nm was prepared on a PI substrate by magnetron sputtering to form a lower AZO conductive layer A. The sputtering conditions were: the sputtering gas was high-purity argon, The sputtering pressure is 0.6Pa, and the aluminum oxide-doped zinc oxide ceramic target is used in this embodiment, and the mass percentage of aluminum oxide is 1%;

[0081] (2) Prepare a silver nanowire suspension, and apply the silver nanowire suspension to the lower AZO conductive layer A by spin coating to form a silver nanowire conductive layer B, wherein the silver nanowire suspension is prepared Include the following steps:

[0082] (2-1) Magnetically stir 50ml of 0.3mol / L polyvinylpyrrolidone solution in ethylene glycol under heating at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com