Novel method for synthesis of tetrammine platinum hydrogen nitrate (II)

A technology of tetraammine platinum nitrate and platinum diiodide diammine, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc., can solve high cost, expensive, The problem of poor economic feasibility and other problems, to achieve the effect of high yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

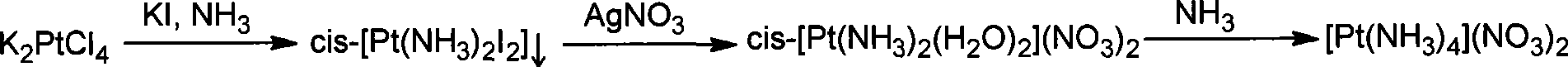

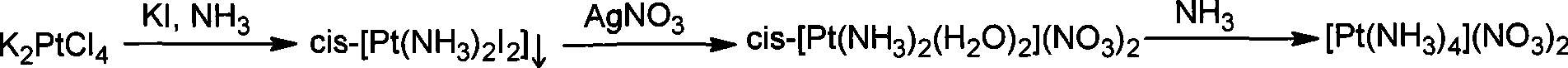

[0013] (1) cis-[Pt(NH 3 ) 2 I 2 ] Preparation of intermediate

[0014] Weigh 100g K 2 PtCl 4 (241mmol) was dissolved in 500ml of water, and the insolubles were removed by filtration. At 45°C, 200ml of an aqueous solution containing KI 240g (1.45mol, excess 50%) was slowly added, and after 4 hours of reaction in the dark, 1:1 ammonia water (excess 30%), a yellow precipitate was obtained, left for 2 hours, collected by filtration, washed with water and ethanol respectively, and then vacuum-dried at 60-70°C for 4 hours to obtain cis-[Pt(NH 3 ) 2 I 2 ] 112 g, yield 96%, platinum content 39.7% (calculated value 40.4%).

[0015] (2)[Pt(NH 3 ) 4 ](NO 3 ) 2 Synthesis

[0016] Weigh 100g of cis-[Pt(NH 3 ) 2 I 2 ] (207mmol), suspended in 500ml of water, added equivalent silver nitrate 70.3g (414mmol), stirred and reacted at 45°C for 5 hours, checked that the reaction was complete, filtered to remove the AgI precipitate, and the mother liquor was freeze-dried to nearly dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com