Method for preparing bimetallic denitration catalyst by using coal ash

A denitration catalyst, fly ash technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of insufficient comprehensive utilization of fly ash and the cost of denitration catalysts Advanced problems, to achieve significant economic benefits, easy control of process conditions, saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

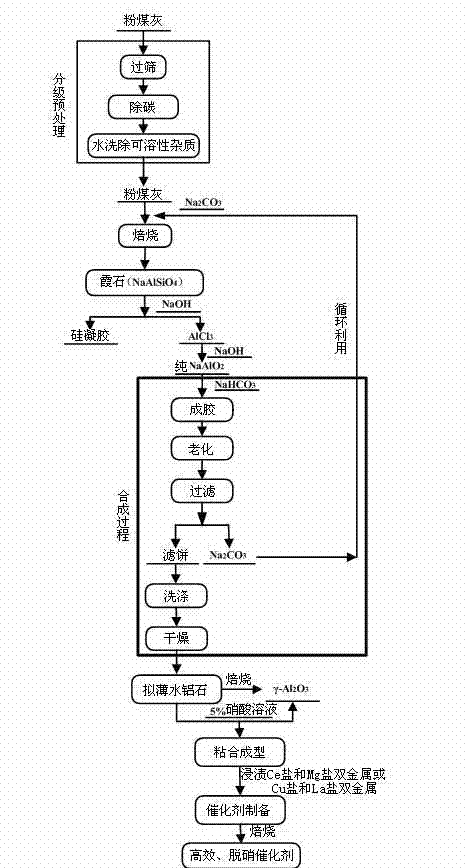

[0027] combine figure 1 As shown, the method of using fly ash to prepare bimetallic denitrification catalyst: collect fly ash from the site, grind it into fine powder, pass through a 200-mesh sieve, take 100g of fine powder and place it in a muffle furnace. After calcination at high temperature for 6 hours, wash with water 3 times at a temperature of 45°C and a speed of 200r / min, 2 hours each time, then separate the washing liquid from the fly ash for solid-liquid separation, and dry the solid at 120°C for 5 hours after separation; Ash and Na 2 CO 3 The solid mass ratio is 1:0.8 and mixed evenly. After roasting at 800°C for 1 hour, take it out to 25°C for later use; then impregnate the roasted product with 6.4mol / L HCl for 1 hour, filter to remove insoluble matter, and obtain silica-rich gel and crude AlCl 3 solution.

[0028] The crude AlCl prepared above 3 Adjust the pH value of the solution to 6, filter and wash the resulting precipitate, then continue to drop NaOH to dis...

Embodiment 2

[0033] This method of using fly ash to prepare bimetallic denitration catalysts: collect fly ash on site, grind it into fine powder, pass through a 200-mesh sieve, take 100g of fine powder and place it in a muffle furnace, and calcinate it at 900°C for 10 hours , at a temperature of 45°C and a rotational speed of 300r / min, wash with water three times, each time for 3 hours, then separate the washing liquid from the fly ash solid-liquid, and dry the separated solid at 120°C for 5 hours for later use; fly ash and Na 2 CO 3 The mass ratio of solids is 1:1.5, mixed evenly, roasted at 880°C for 1.5h, then taken out to 25°C for use; then impregnated the roasted product with 7.2mol / L HCl for 2.5h, filtered to remove insoluble matter, and obtained silica-rich gel and Crude AlCl 3 solution.

[0034] The crude AlCl prepared above 3 Adjust the pH value of the solution to 6, filter and wash the resulting precipitate, then continue to drop NaOH to dissolve the precipitate until the pH i...

Embodiment 3

[0039] This method of using fly ash to prepare a bimetallic denitrification catalyst: collect fly ash from the site, grind it into a fine powder, pass through a 200-mesh sieve, take 100g of the fine powder and place it in a muffle furnace, and calcinate it at 600°C for 8 hours Finally, wash once with water at a temperature of 20°C and a rotational speed of 100r / min, 4 hours each time, then separate the washing liquid from the fly ash for solid-liquid separation, and dry the solid at 120°C for 5 hours after separation; fly ash and Na 2 CO 3 The mass ratio of solids is 1:0.4, mixed evenly, roasted at 750°C for 2 hours, then taken out to 25°C for later use; then impregnated the roasted product with 2mol / L HCl for 3 hours, filtered, and removed the insoluble matter to obtain silica-rich gel and crude AlCl 3 solution. Crude AlCl 3 The pH value of the solution is adjusted to 4, the precipitate generated is filtered and washed, and then NaOH is continued to be added dropwise to dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com