Carbonyl iron powder/lanthanum strontium manganate composite and preparation method thereof

A carbonyl iron powder, composite material technology, applied in chemical instruments and methods, other chemical processes, radiation-absorbing coatings, etc. Thin, lightweight and other issues, to achieve the effect of good absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

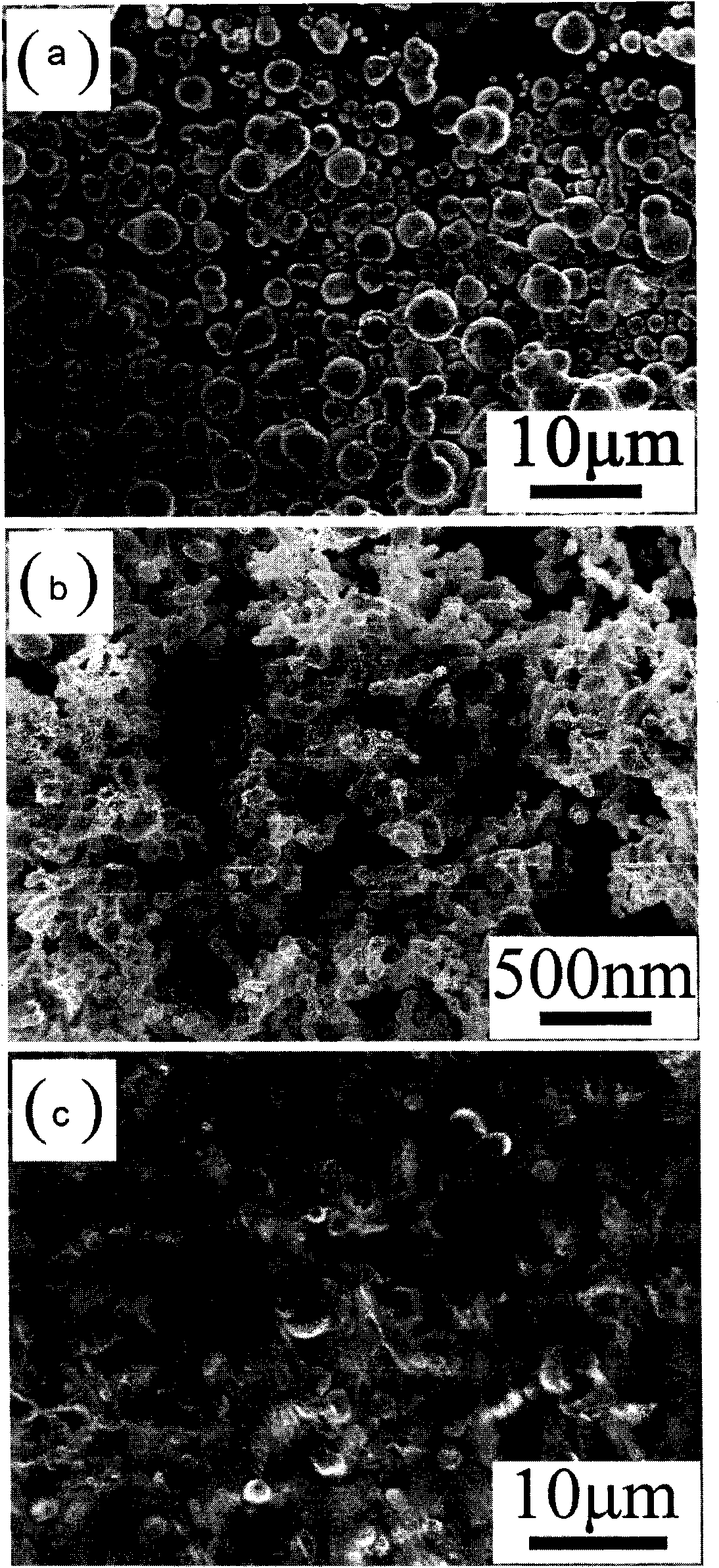

Image

Examples

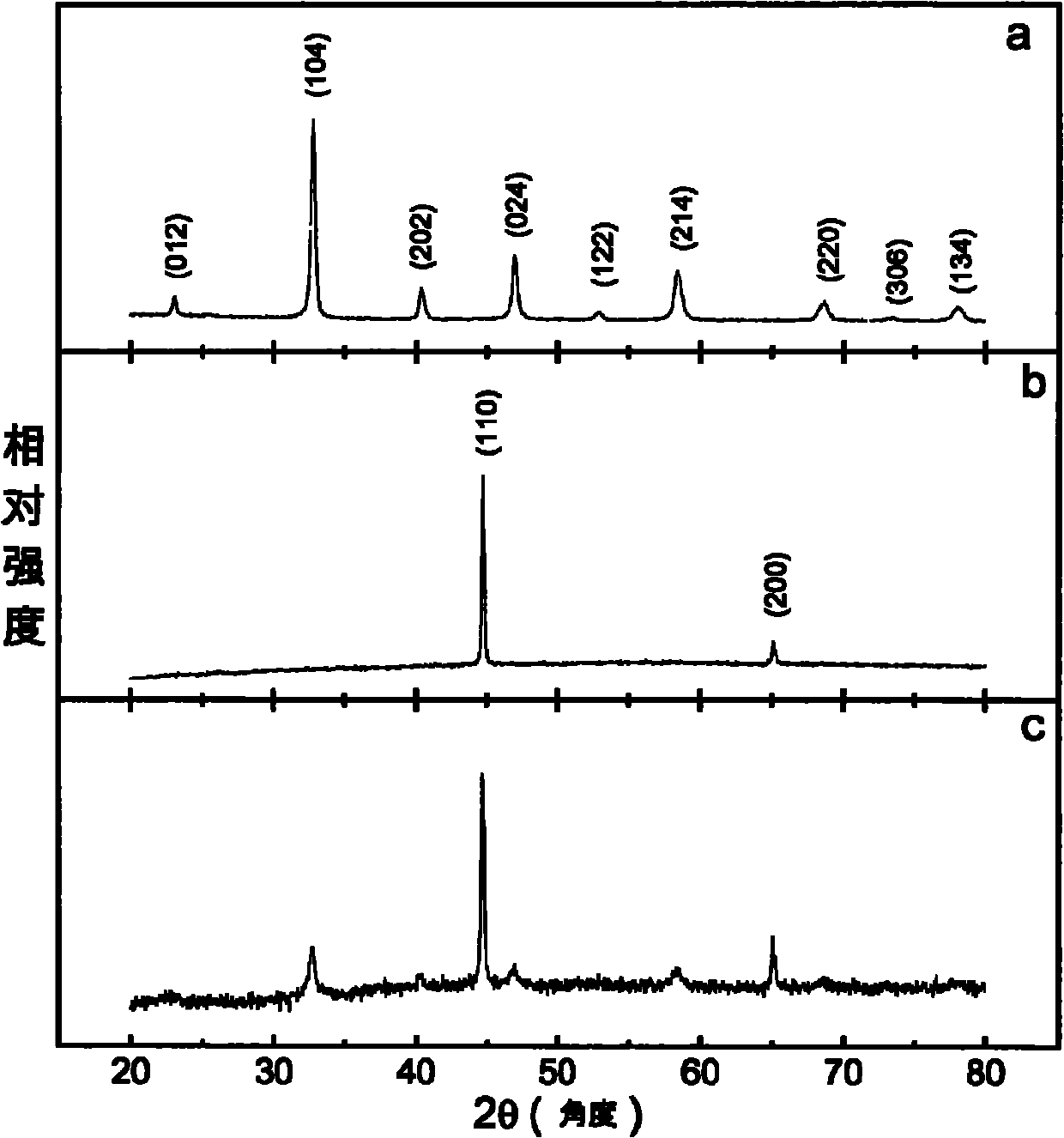

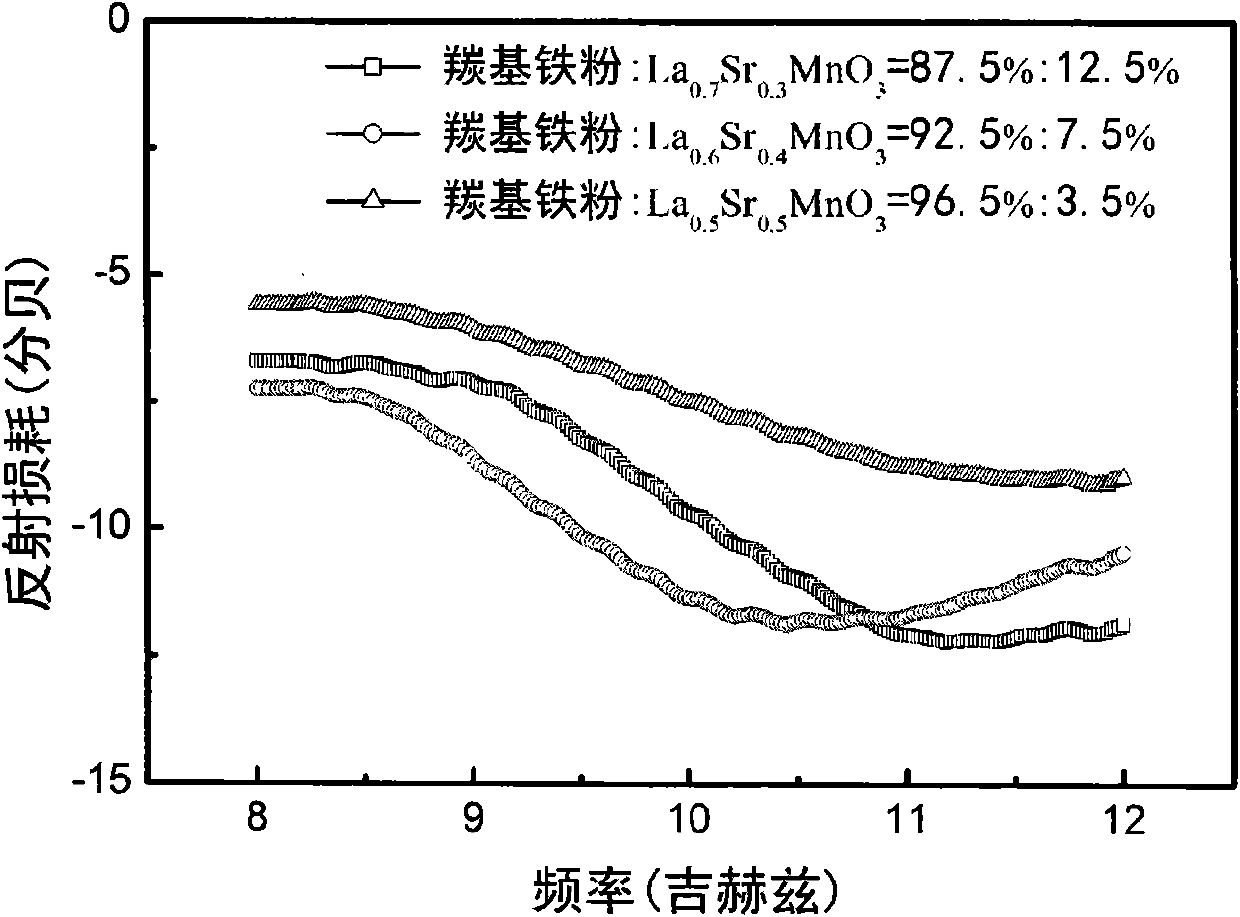

Embodiment 1

[0020] The concrete steps of preparation are:

[0021] Step 1, first lanthanum oxide, strontium carbonate and manganese carbonate according to La 1-x Sr x MnO 3 The stoichiometric ratio is added into the aqueous solution of nitric acid under stirring until it is completely dissolved to obtain a mixed solution; wherein, La 1-x Sr x MnO 3x in the powder is 0.25, the volume ratio of nitric acid:water in the nitric acid aqueous solution is 1:50, and the water is deionized water. Add citric acid to the mixed solution placed at 60° C. to obtain an intermediate solution, wherein the molar ratio between citric acid and manganese carbonate in the mixed solution is 2:1. Next, first add ammonia water dropwise to the intermediate liquid until its pH value is 6, and place it at 60°C to continue stirring until a gel is formed; then place the gel at 100°C to keep warm until the gel is dried, Obtain gel dry powder. Afterwards, the dry gel powder was pre-calcined at 200°C for 4 hours, a...

Embodiment 2

[0024] The concrete steps of preparation are:

[0025] Step 1, first lanthanum oxide, strontium carbonate and manganese carbonate according to La 1-x Sr x MnO 3 The stoichiometric ratio is added into the aqueous solution of nitric acid under stirring until it is completely dissolved to obtain a mixed solution; wherein, La 1-x Sr x MnO 3 x in the powder is 0.33, the volume ratio of nitric acid:water in the nitric acid aqueous solution is 1:63, and the water is distilled water. Add citric acid to the mixed solution placed at 69° C. to obtain an intermediate solution, wherein the molar ratio between citric acid and manganese carbonate in the mixed solution is 3.5:1. Next, add ammonia water dropwise to the intermediate solution until its pH value is 6.3, and place it at 69°C to continue stirring until a gel is formed; then place the gel at 115°C to keep warm until the gel is dried, Obtain gel dry powder. Afterwards, the dry gel powder was pre-calcined at 235°C for 3.5 hours...

Embodiment 3

[0028] The concrete steps of preparation are:

[0029] Step 1, first lanthanum oxide, strontium carbonate and manganese carbonate according to La 1-x Sr x MnO 3 The stoichiometric ratio is added into the aqueous solution of nitric acid under stirring until it is completely dissolved to obtain a mixed solution; wherein, La 1-x Sr x MnO 3 x in the powder is 0.4, the volume ratio of nitric acid:water in the nitric acid aqueous solution is 1:75, and the water is deionized water. Add citric acid to the mixed solution placed at 78° C. to obtain an intermediate solution, wherein the molar ratio between citric acid and manganese carbonate in the mixed solution is 5:1. Next, add ammonia water dropwise to the intermediate liquid until its pH value is 6.5, and place it at 78°C to continue stirring until a gel is formed; then place the gel at 130°C to keep warm until the gel is dried, Obtain gel dry powder. Afterwards, the dry gel powder was pre-calcined at 275°C for 3 hours, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com