Method for preparing nano-silver wire with high length-diameter ratio

A technology of nano-silver wire and high aspect ratio, which is applied in the field of preparation of high-aspect-ratio nano-silver wire, can solve the problems of complex reaction conditions, long dropping time, poor conductivity, etc., and achieve simple preparation process and uniform length Good, easy-to-reproduce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

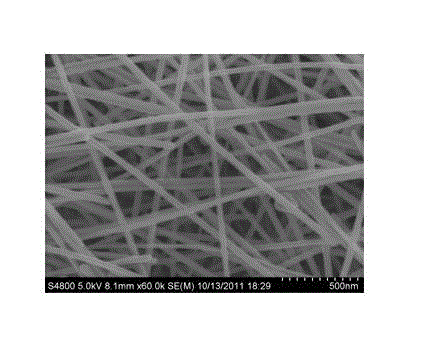

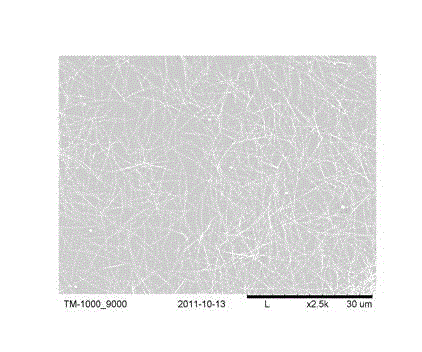

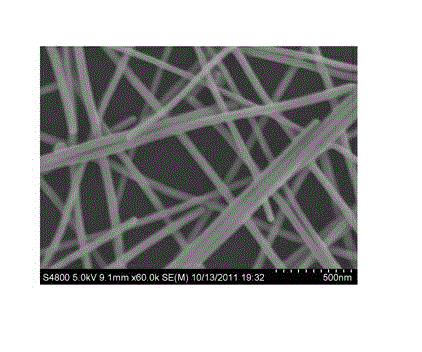

[0075] The present invention provides two preparation methods of high aspect ratio nano-silver wires, the first method is: the following substances

[0076] 1) At least one polyhydroxy liquid organic compound;

[0077] 2) Silver nitrate;

[0078] 3) Polyvinylpyrrolidone (PVP) with a K value of 30 or above;

[0079] 4) At least one chloride compound that is soluble in polyhydroxy liquid organic matter and can produce chloride ions after dissolution;

[0080] 5) At least one hydrogen-containing compound, which is soluble in polyhydric liquid organic matter and can generate hydrogen ions after dissolution;

[0081] To form a reaction solution, the amount of the above substances needs to meet the following conditions: the molar concentration of silver nitrate is not higher than 0.1mol / L, the molar concentration of polyvinylpyrrolidone is not higher than 1.0mol / L, and the molar ratio of chloride ions to silver ions is at 1:10000~1:100, the molar ratio of hydrogen ion to silver i...

Embodiment 1

[0130] 1. Prepare the polyhydroxy liquid organic matter solution as follows:

[0131] A: Concentration is the ethylene glycol solution of the silver nitrate of 0.2mol / L;

[0132] B: Ethylene glycol solution with a concentration of 0.4mol / L polyvinylpyrrolidone (PVP, K30);

[0133] 2. Take 1000ml of ethylene glycol solution of silver nitrate prepared above and 1000ml of ethylene glycol solution of polyvinylpyrrolidone (PVP, K30), mix them well, stir them well, and add 37.5% of them under the condition of 60℃ 0.05g of concentrated hydrochloric acid and 0.1g of concentrated nitric acid with a concentration of 65%, continue to stir evenly to form a reaction precursor, and heat the precursor solution by microwave to make it react at a temperature of 155°C for a reaction time of more than 10 minutes, so that The chemical reaction in the solution is completed or partially completed, and the nano-silver wire or the dispersion liquid of the nano-silver wire is obtained after solid-liq...

Embodiment 2

[0135] 1. First, prepare the ethylene glycol solution with the following concentration:

[0136] A: concentration is the silver nitrate ethylene glycol solution of 0.2mol / L;

[0137] B: Ethylene glycol solution of polyvinylpyrrolidone (PVP) with a concentration of 0.4mol / L;

[0138] 2. Take 1000ml of the above-mentioned ethylene glycol solution of polyvinylpyrrolidone (PVP), and add 0.1g of diphenylphosphine chloride and 0.05g of concentrated hydrochloric acid with a concentration of 37.5% to it, mix and stir well to form a mixed solution ;

[0139] 3. Use an oil bath to heat the mixed solution so that the temperature of the solution reaches 120°C, add the standby silver nitrate solution to it, and after the dropwise addition, make the whole solution continue to react at 140°C for more than 60 minutes to make the solution The chemical reaction that takes place is completed to form a solution of silver nanowires, and the silver nanowires or dispersion liquid of silver nanowir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com