Surfactant hydrothermal method for preparing leaf-shaped, tubular and paraphlomis-kwangtungensis-shaped BiVO4

A technology of surfactant and hydrothermal method, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., to achieve the effect of simple process, controllable crystal structure and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

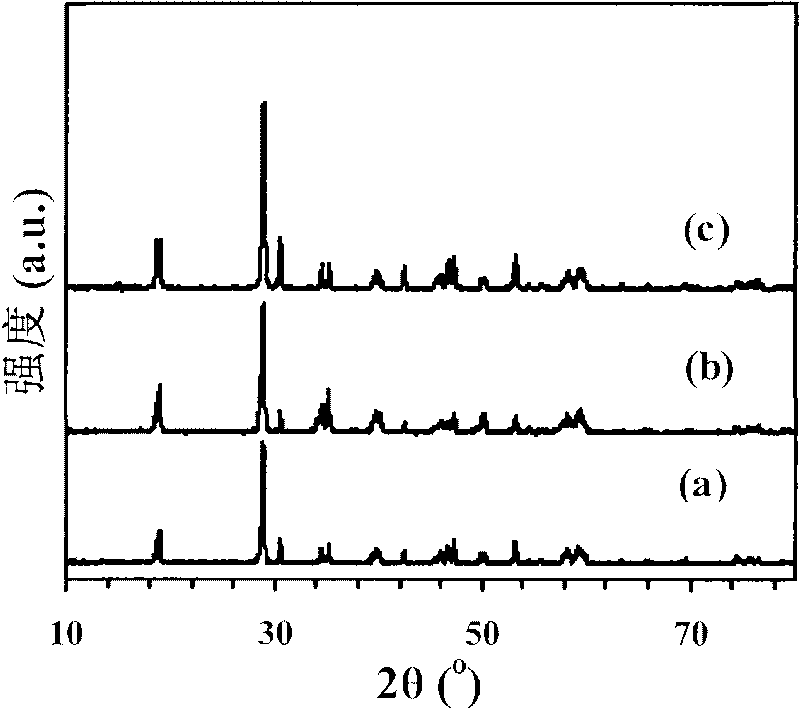

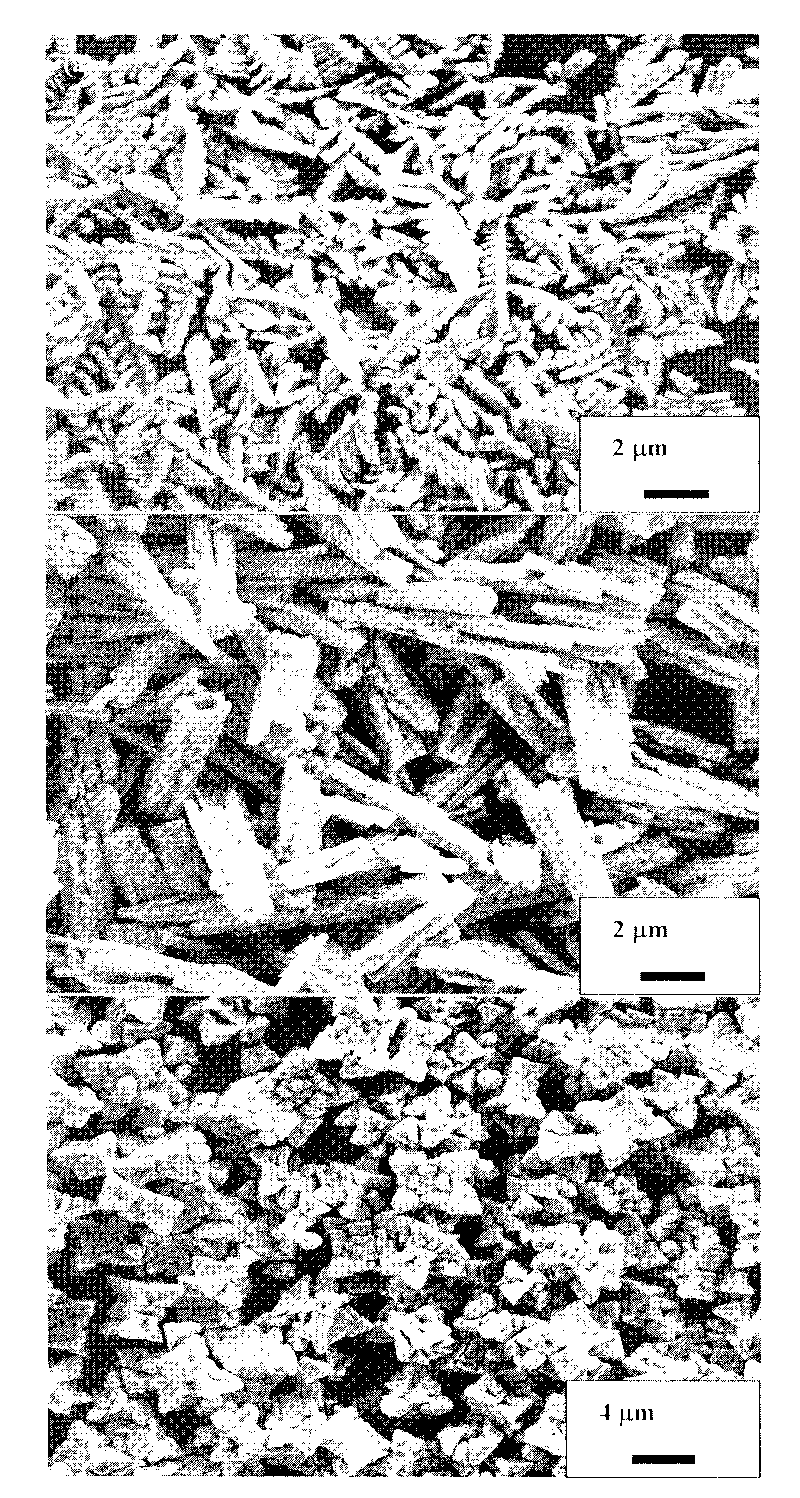

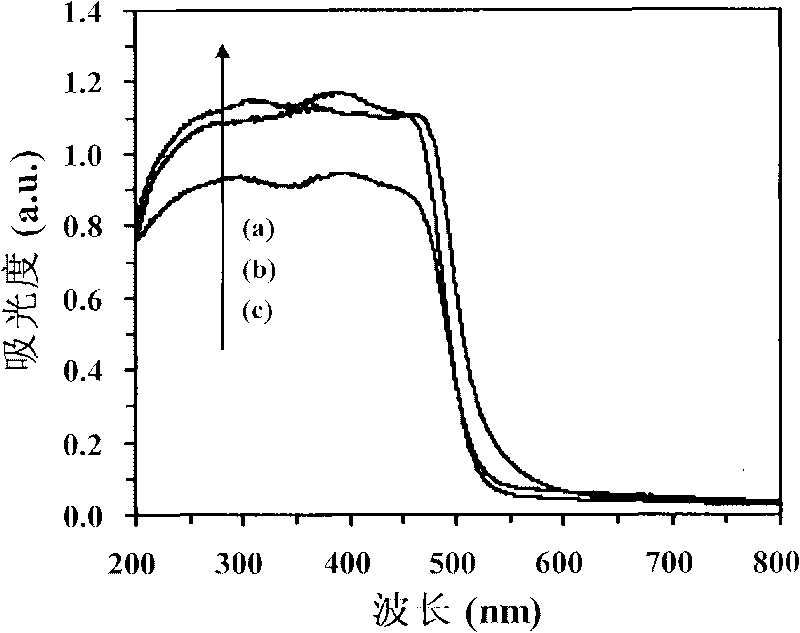

[0015] Embodiment 1: Under stirring condition, 1.972g triblock copolymer P123 (PEO 20 PPOs 70 PEOs 20 ) into 50mL HNO 3 solution (2mol / L), then add 10mmolBi(NO 3 ) 3 ·5H 2 O, add 10mmol NH at the end 4 VO 3 , to obtain a yellow solution after dissolving completely, adjust the pH value of the mixed solution to 9 with 14wt% ammoniacal liquor, transfer the gained solution to an autoclave (volume filling degree) equipped with a polytetrafluoroethylene liner (volume is 100mL) 80%) at a constant temperature of 180°C for 6 hours, after suction filtration, washing with water for 3 times and absolute ethanol for 3 times, the obtained yellow powder was dried at 60°C for 12 hours, and then dried in a muffle furnace at a temperature of 1°C / min in an air atmosphere. The rate was increased from room temperature to 400° C. and kept at this temperature for 4 hours, and leaf-shaped bismuth vanadate microparticles with a monoclinic crystal structure were obtained, and the absorption boun...

Embodiment 2

[0016] Example 2: Under stirring conditions, 1.972g P123 was added to 50mL HNO 3 solution (2mol / L), then add 10mmol Bi(NO 3 ) 3 ·5H 2 O, add 10mmol NH at the end 4 VO 3 , after dissolving completely, obtain yellow solution, adjust the pH value of mixed solution to 10 with the ammoniacal liquor of 14wt%, transfer gained solution in the autoclave (volume filling degree) that polytetrafluoroethylene liner (volume is 100mL) is housed 80%) at a constant temperature of 180°C for 6 hours, after suction filtration, washing with water for 3 times and absolute ethanol for 3 times, the obtained yellow powder was dried at 60°C for 12 hours, and then dried in a muffle furnace at a temperature of 1°C / min in an air atmosphere. The rate was increased from room temperature to 400° C. and kept at this temperature for 4 hours, and tubular bismuth vanadate microparticles with a monoclinic crystal structure were obtained, and the absorption boundary was 520 nm. Its XRD spectrum is shown in f...

Embodiment 3

[0017] Example 3: Under stirring conditions, 1.972g P123 was added to 50mL HNO3 solution (2mol / L), then add 10mmol Bi(NO 3 ) 3 ·5H 2 O, add 10mmol NH at the end 4 VO 3 , to obtain a yellow solution after dissolving completely, adjust the pH value of the mixed solution to 3 with 14wt% ammoniacal liquor, transfer the gained solution to an autoclave (volume filling degree) equipped with polytetrafluoroethylene liner (volume is 100mL) 80%) at a constant temperature of 80°C for 6 hours, after suction filtration, washing with water for 3 times and absolute ethanol for 3 times, the obtained yellow powder was dried at 60°C for 12 hours, and then dried in a muffle furnace at a temperature of 1°C / min in an air atmosphere. The rate was increased from room temperature to 400° C. and kept at this temperature for 4 hours, and octagonal-shaped bismuth vanadate microparticles with a monoclinic crystal structure were obtained, and the absorption boundary was 533 nm. Its XRD spectrum is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com