Compound acidifying liquid containing nitric acid and boratofluroic acid and its use method

A technology of fluoboric acid and acidizing fluid, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc. It can solve the problems of poor plugging removal effect, achieve the effects of preventing corrosion, ensuring construction safety, and excellent corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

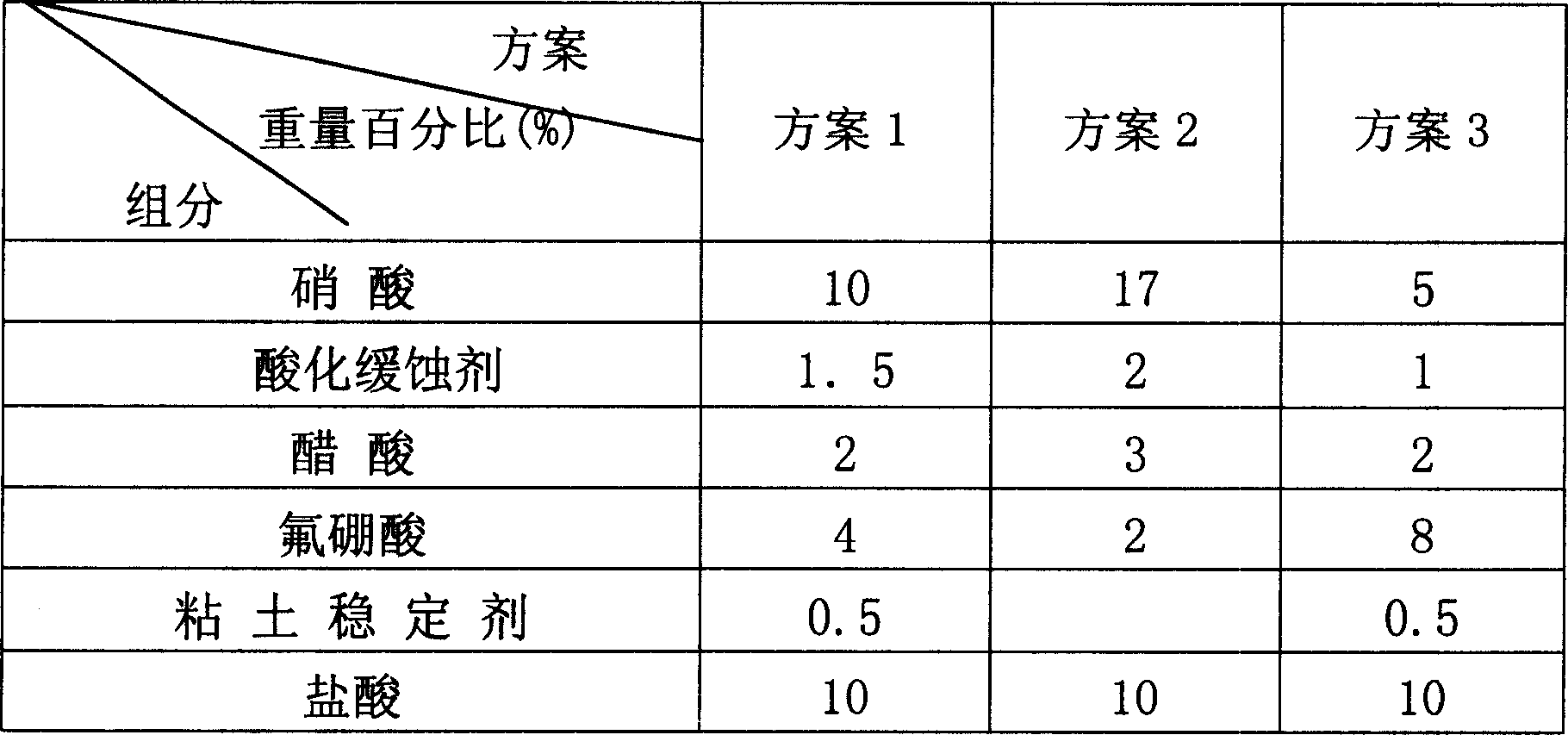

[0032] Example 1. A water injection well in the No. 1 mine of the No. 3 Oil Production Plant in Daqing. The well depth of the sandstone oil layer is 1215 meters, the formation temperature is 50° C., the quartz content is 75%, the shale content is 8%, and the feldspar content is 17%. The effective thickness of the perforation is 1.6 meters, and the water absorption is 1 meter under the water injection pressure of 15.5 MPa 3 / day, less than 30 meters 3 / Day of dispensing requirements. After analysis, the decline in water injection capacity was due to mixed clogging caused by metabolites of sulfate-reducing bacteria and clay swelling. Use scheme 1 in the above table to carry out acidification and deblocking. The amount of compound acidizing fluid per meter of formation is 4 meters 3 , with an average displacement of 0.4 m 3 / min, the replacement fluid is water. The residence time of the acid solution in the formation is 6 hours, and the acidified residual liquid is directl...

Embodiment 2

[0033] Example 2. A water injection well in the No. 1 mine of the No. 3 Oil Production Plant in Daqing. The depth of the sandstone reservoir is 985 meters, the formation temperature is 40° C., the content of quartz is 75%, the content of shale is 5%, and the content of feldspar is 20%. The effective thickness of the perforation is 5 meters, and the water absorption is 5 meters under the water injection pressure of 13.7MPa 3 / day, while the allocation requirement is 80 meters 3 / day. After analysis, the main reason for the decline of water injection capacity is the metabolites of sulfate-reducing bacteria, and the migration of clay particles is the secondary reason. Use scheme 2 in the above table to carry out acidification and deblocking. The amount of compound acidizing fluid per meter of formation is 2 meters 3 , with an average displacement of 0.4 m 3 / Minute. The acid liquid stays in the formation for 8 hours, and after the well is opened and blown out, it is discharg...

Embodiment 3

[0034] Example 3, a water injection well in the No. 1 mine of the No. 3 Oil Production Plant in Daqing, the depth of the sandstone reservoir is 1545 meters, the formation temperature is 55°C, the content of quartz is 55%, the content of mud is 20%, the content of feldspar is 20%, and the content of carbonate is 5%. . The effective thickness of the perforation is 12 meters, and the water absorption is only 5 meters under the water injection pressure of 15.2MPa 3 / day, while the allocation requirement is 30 meters 3 / day. After analysis, the main reason for the decline of water injection capacity is the migration and swelling of clay particles, and the scaling and bacterial metabolites are the secondary reasons. Use the acidizing solution of Scheme 2 in the above table to get rid of the blockage. The amount of compound acidizing fluid per meter of formation is 6 meters 3 , use water as a replacement solution. During construction, the average displacement is 0.35 meters 3 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com