Method for separating and recycling copper, nickel and regenerative plastic from waste electroplating plastic

A technology of electroplating plastics, separation and recycling, which is applied in the direction of plastic recycling, recycling technology, process efficiency improvement, etc., and can solve problems that affect the strength, appearance and bonding performance of recycled plastics, waste of metal resources, and reduce the value of recycling. , to achieve the effect of easy industrial production, high income and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The ABS electroplating plastic used in this test was analyzed, and the composition is as follows:

[0026]

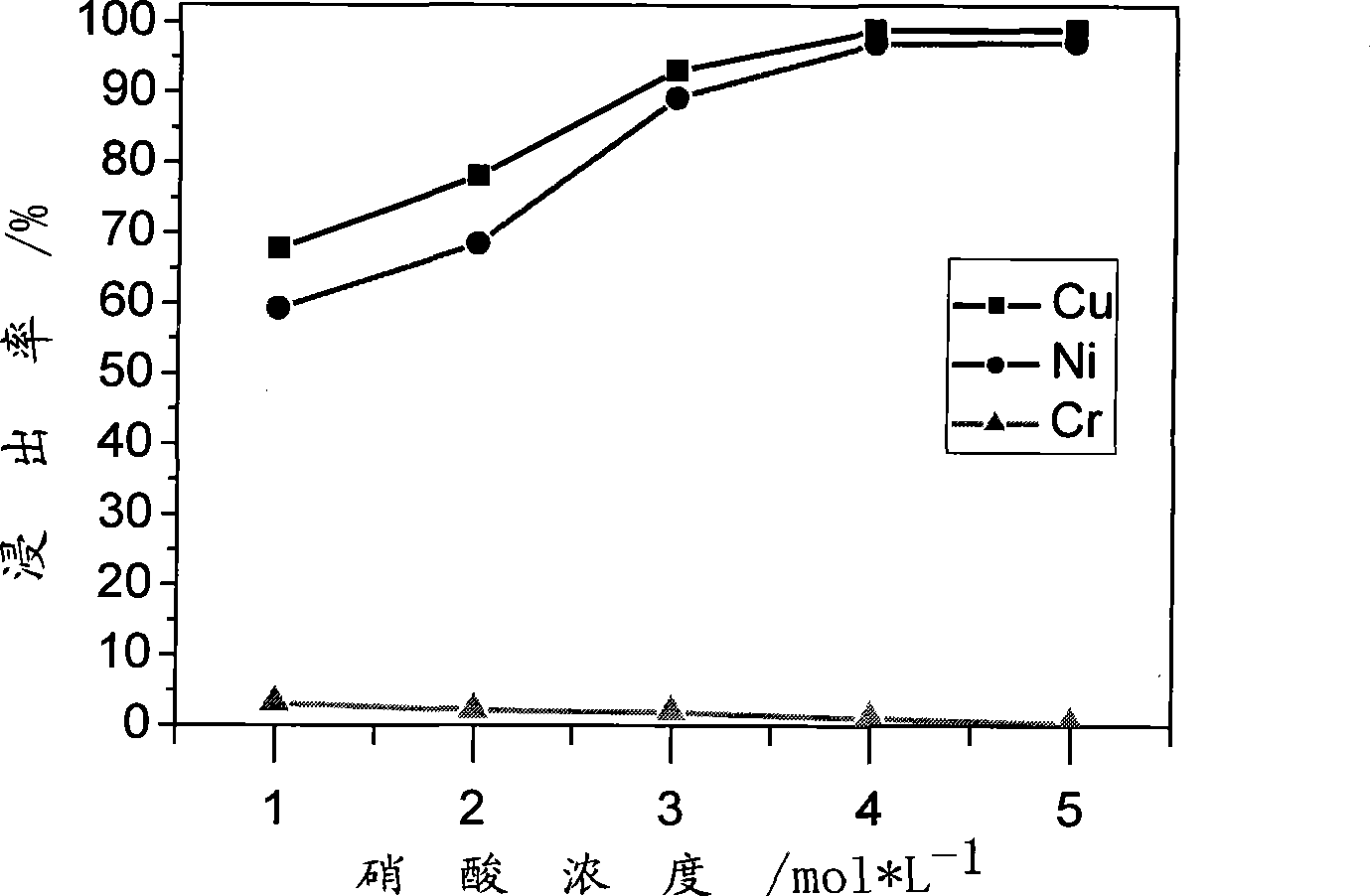

[0027] Take 1Kg of the above-mentioned electroplated plastics and process them into fragments with a particle size of less than 5mm with a crusher, put them into 1.5 liters of 4mol / L nitric acid solution, control the reaction temperature to 60°C, and the reaction time to 4h. 2.0L, each metal content in the solution is measured as follows:

[0028]

[0029] After calculation, the leaching rate of nickel is 98.35%, the leaching rate of copper is 99.05%, and the leaching rate of chromium is only 1.1%.

Embodiment 2

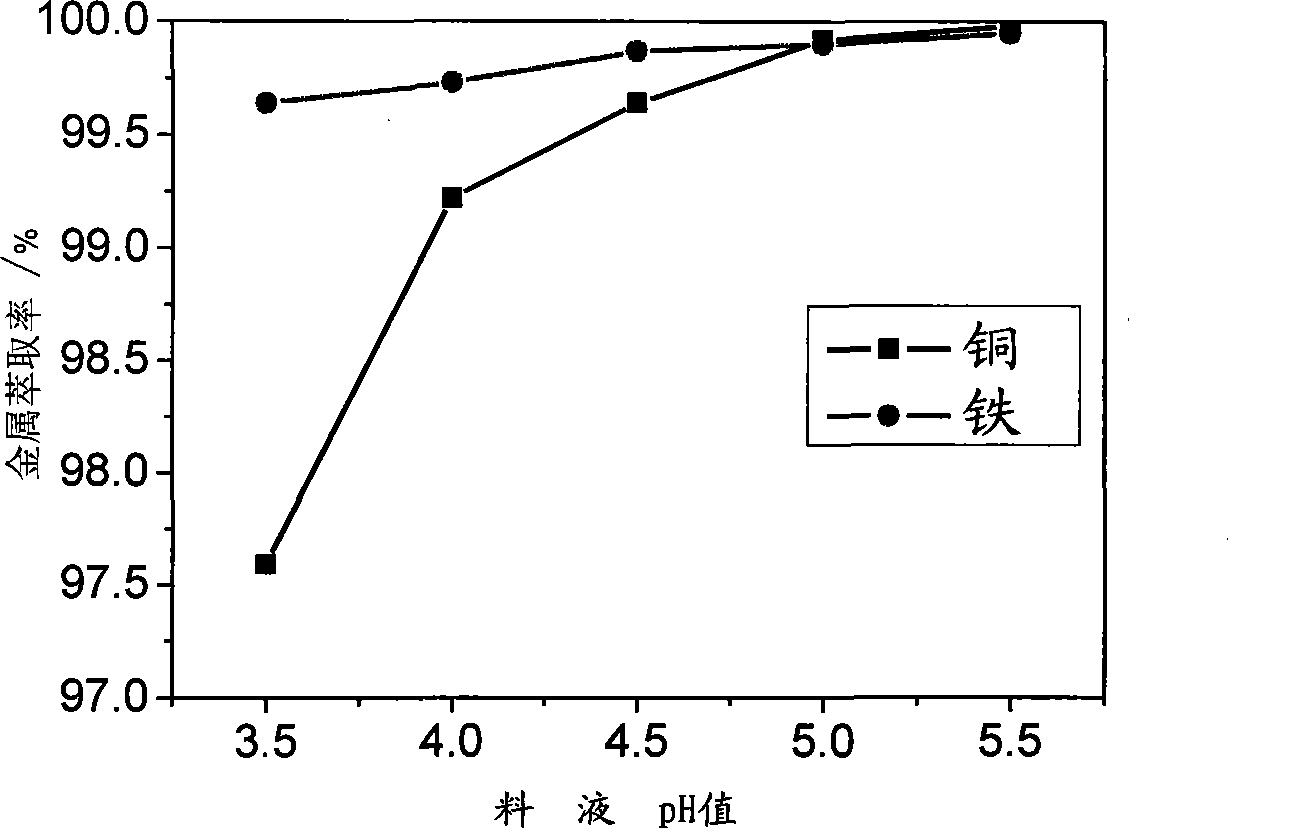

[0031] Take 1 L of the leaching solution in Example 1, adjust the pH value of the solution to 3.5, calculate according to the copper ion content in the solution, add 18.89 g of iron powder (1.05 times the theoretical amount), the reaction temperature is 75 ° C, mechanically stirred, and the reaction time is 3 h . After the reaction is finished, filter and wash, the solution is settled to the original volume, and the content of each metal is analyzed as follows:

[0032]

[0033] After calculation, the replacement rate of copper is 98.97%. After drying the filter residue and separating iron by magnetic separation, 21.01 g of sponge copper was obtained, and its copper content was analyzed to be 99.85%.

Embodiment 3

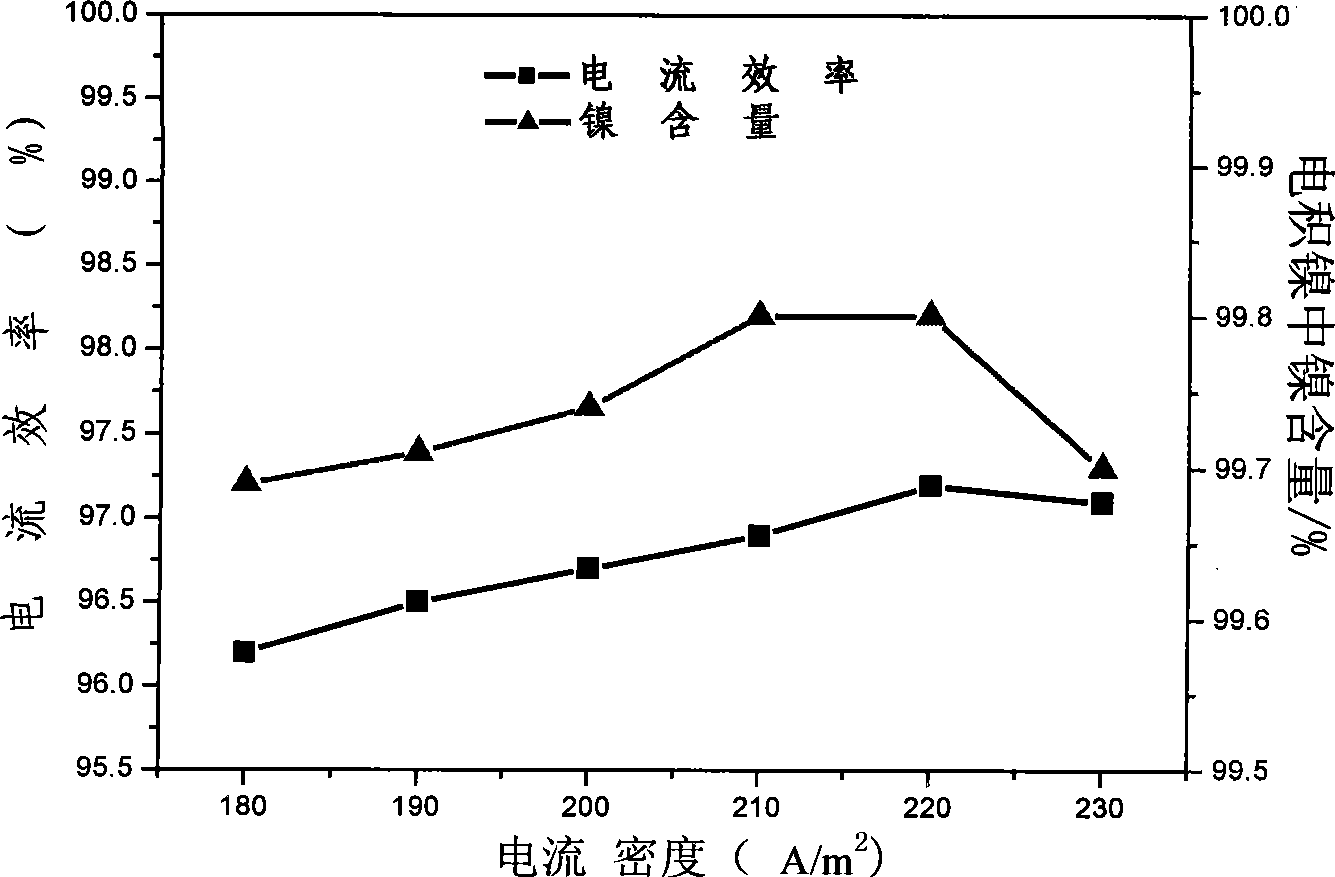

[0035] Take 1.0L of the solution in Example 2, put it in a 3L beaker, add 13.43g of sodium sulfate, adjust the pH value of the solution system to 2.5, control the water melting temperature to 95°C, and the mechanical stirring rate to 500r / min. After continuing the reaction for 2.5h, Filter, after filtering out the yellow jarosite precipitation, the filtrate is settled to the original volume, and the analysis of the filtrate components is as follows:

[0036]

[0037] After calculation, the removal rate of iron ions is 97.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com