A magnetic hollow micro-nano material and its preparation method and application

A micro-nano and micro-nano ball technology, applied in the field of magnetic hollow micro-nano materials and their preparation, and the field of preparing magnetic hollow micro-nano materials, can solve the problems of strict requirements on instrument accuracy, cumbersome steps, long time consumption, etc., to achieve structural and The formation mechanism is novel, the production equipment is simple, and the production cycle is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The invention also discloses a preparation method of magnetic hollow micro-nano material, the specific steps include:

[0049] (1) Dissolving copper salt, nickel salt and ethylenediamine in alkali solution, stirring and reacting at room temperature for 20-40 minutes, to obtain mixture 1;

[0050] (2) Add hydrazine hydrate to mixture 1, feed oxidizing gas at the same time, heat and stir, wait for the reaction to be completed, drop to room temperature, obtain mixture 2;

[0051] (3) The mixture 2 was centrifugally filtered, washed three times, and then dried to finally obtain the magnetic hollow micro-nano material disclosed in the present invention.

[0052] In order to further optimize the above-mentioned technical scheme, in the reaction system of step (1), the ratio of the addition amount of nickel salt to copper salt is (1~20):1, and the concentration of nickel salt is 0.5~8.0mol / L, ethylene two The concentration of amine is 2-8 mol / L.

[0053] In order to further ...

Embodiment 1

[0058] Prepare 900mL of 7.0M NaOH solution in a 1L beaker, cool to room temperature, and then add 7.8mL of 0.5mol / L Cu(NO 3 ) 2 ·3H 2 O, 4.2mL 0.5mol / L Ni(NO 3 ) 2 ·6H 2 O, 9mL ethylenediamine (EDA) was successively added into the beaker, after stirring for 20-40min, 1.5mL hydrazine hydrate (N 2 h 4 ·H 2 O), then stirred for 20 to 40 minutes, passed into an oxidizing gas at 90°C (air flow rate was 20mL / min) and continued to heat and stir (stirring speed 1200 rpm) for 5 hours, took it out and cooled it to room temperature naturally, and used distilled water, Wash each with absolute ethanol 3 times, centrifuge and dry in a vacuum oven at 40°C to obtain magnetic hollow micro-nanotubes.

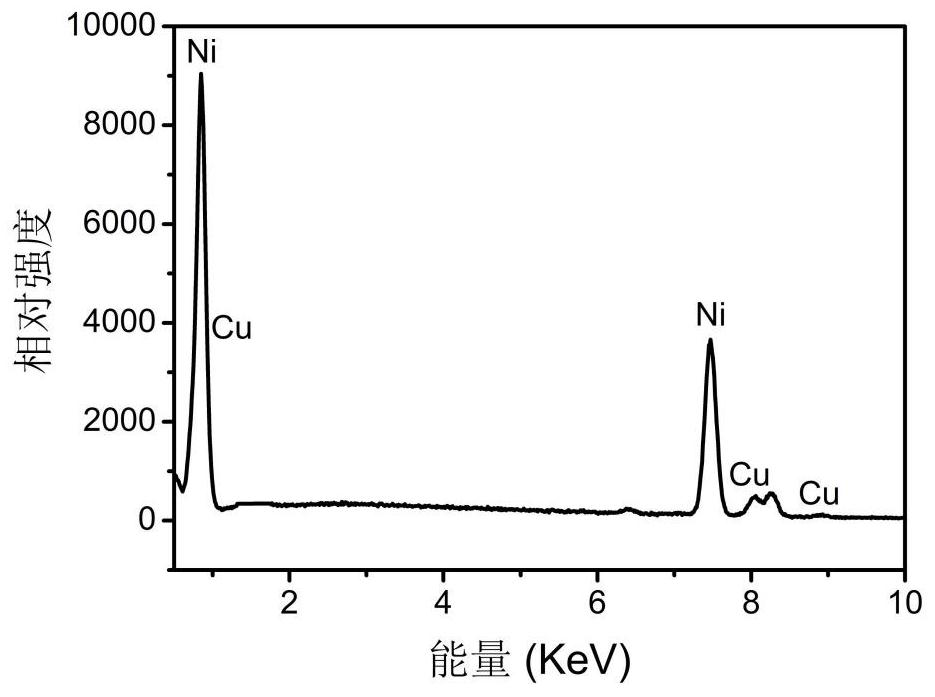

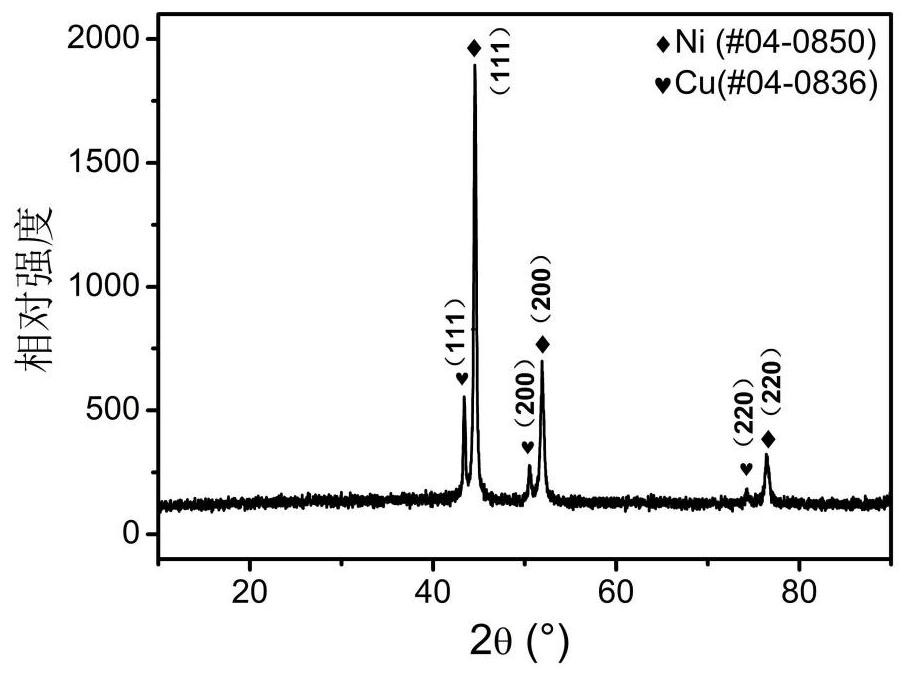

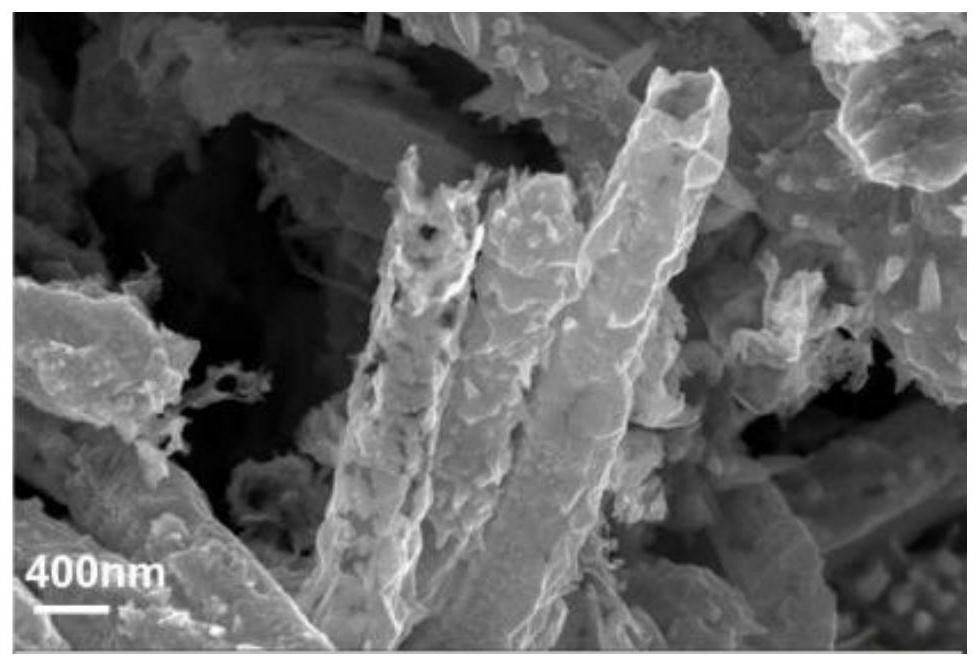

[0059] The composition, phase, morphology and static magnetic properties of the obtained product measured under energy spectrum, XRD, scanning electron microscope and VSM are as follows: Figure 1~4 shown. It can be seen that the product is a homogeneous and monodisperse hollow micro-nan...

Embodiment 2

[0062] Compared with the preparation steps disclosed in Example 1, the only difference is that the reaction temperature is 80° C., and the rest of the preparation steps and process parameters are the same.

[0063] The composition, phase and morphology of the obtained product measured under energy spectrum, XRD and scanning electron microscope are as follows: Figure 6-8 shown. It can be seen that the product is a homogeneous and monodisperse hollow micro-nanotube. Wherein, the diameter of the hollow micro-nanotube is 490-690 nm, the wall thickness is 25-110 nm, the length is about 3-11 μm, and the atomic ratio of Cu / Ni is 0.00685.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com