A single-page printing side shifting device

A single-page, board-moving technology, applied in the direction of transportation and packaging, thin material handling, object separation, etc., can solve the problems of high heat of equipment, waste of time, unfavorable printing, etc., to achieve the effect of meeting the printing task

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

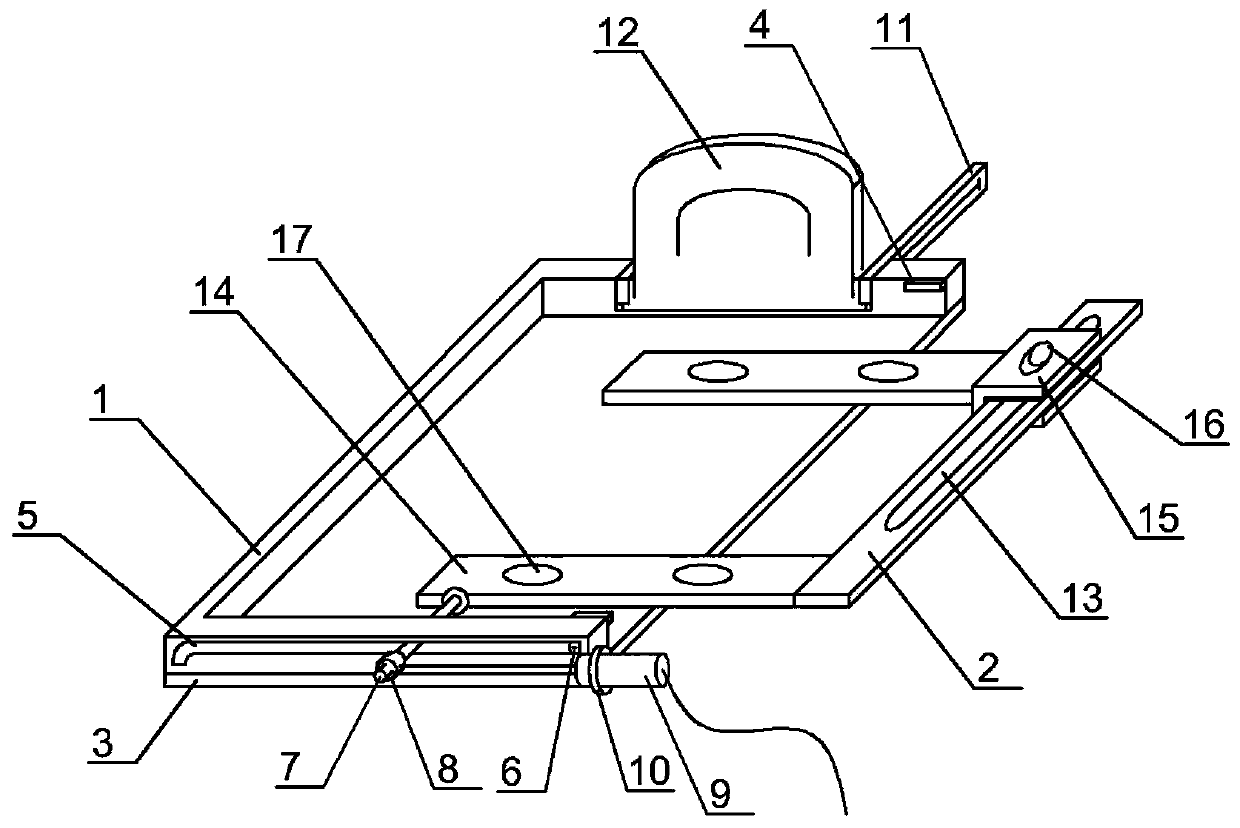

[0016] A side shift device for single-page printing, comprising a side shift main body 1 and a suction side shift main body 2, the side shift main body 1 is fixed on a single-page support base plate 3, and a single-page spacer is provided on the inner wall of the side shift main body 1 4. The front side of the side-moving main body 1 is provided with a side-moving chute 5 , and the right end of the side-moving chute 5 is provided with a spring extrusion piece 6 , and the side-moving linkage rod 7 passes through the side-moving chute 5 , the side shifting sleeve 8 is set on the side shifting linkage rod 7, the side shifting sleeve 8 is connected with the electric telescopic rod 9, and the electric telescopic rod 9 is fixed on the right wall of the side shifting main body 1 through a fixed connection ring 10.

[0017] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com