Paving method of wall covering plate

A laying method and technology of covering panels, applied in covering/lining, architecture, building structure, etc., can solve the problems of reducing the usable area, increasing the thickness of the wall, hidden dangers to personnel health, etc., so as to improve the thermal insulation performance and sound insulation performance, reduce the The effect of the loss of the usable area and the elimination of the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

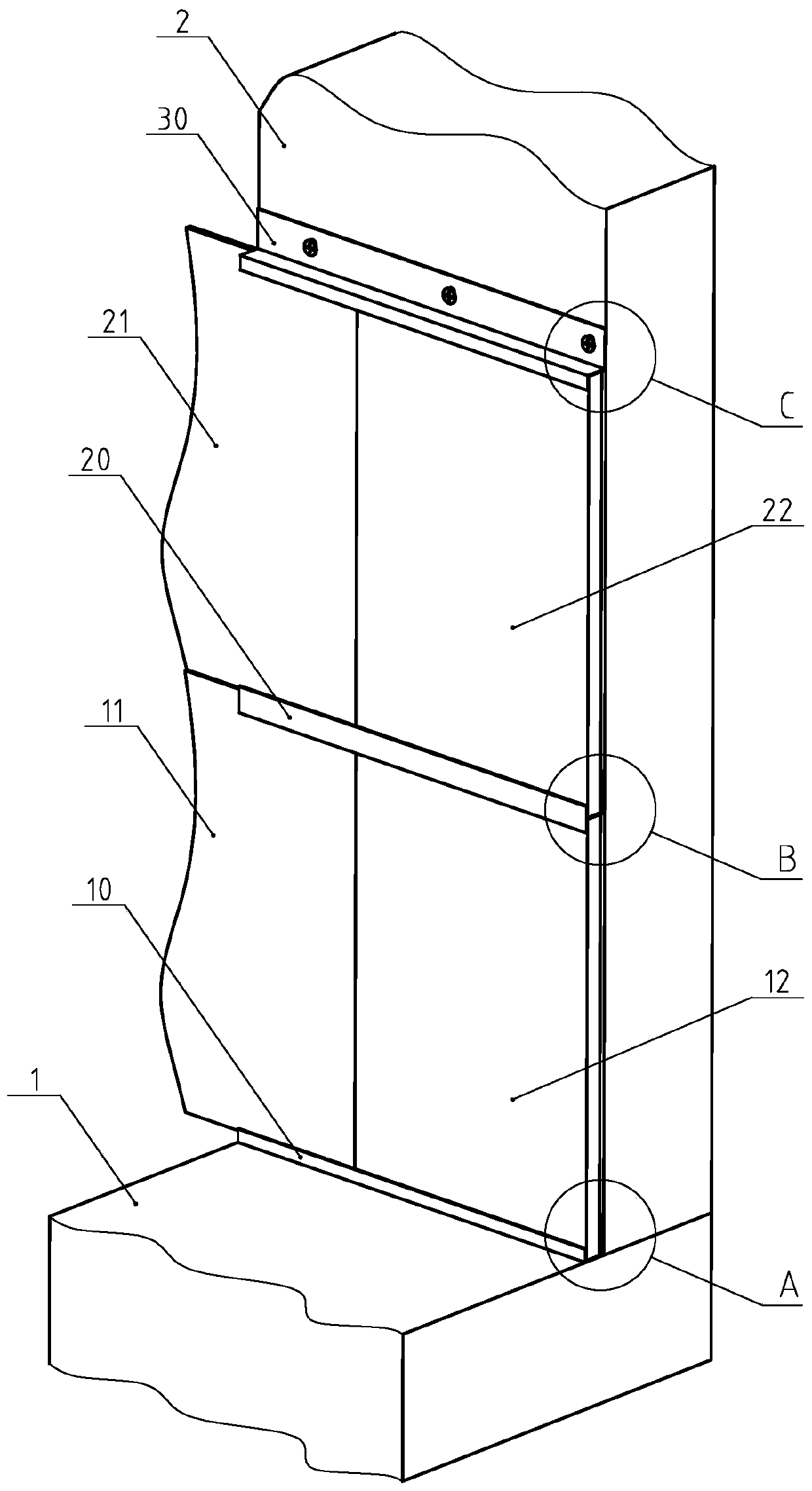

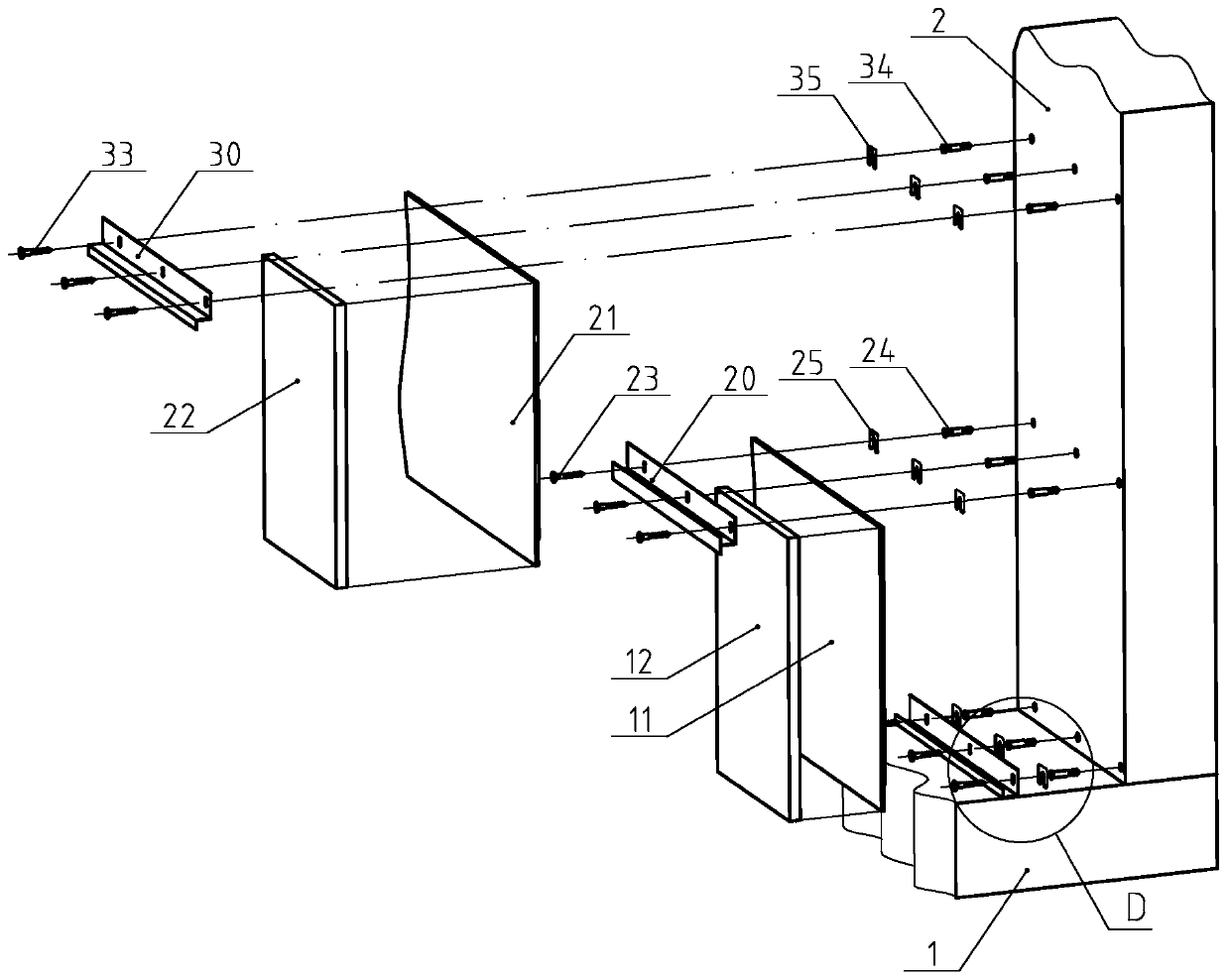

[0059] Such as figure 1 Shown is a completed schematic diagram of a method for laying a wall covering panel disclosed in the present invention. The wall covering panel of this embodiment takes tiles as the implementation object, and the size of the tiles is 600 mm in width, 1200 mm in height, and 11 mm in thickness. . The lower edge of the first ceramic tile is fixed on the wall surface 2 by the first bead 10, and the upper edge of the first ceramic tile is fixed on the wall surface 2 by the second bead 20, and the first ceramic tile and the wall surface 2 are sandwiched between the first ceramic tile and the wall surface 2. One pearl cotton 11. The lower edge of the second ceramic tile is fixed on the wall 2 by the second bead 20, the upper edge of the second ceramic tile is fixed on the wall 2 by the third bead 30, and the second ceramic tile and the wall 2 are clamped Two pearl cotton 21, the thickness of pearl cotton is 5 millimeters. This embodiment takes the laying of...

Embodiment 2

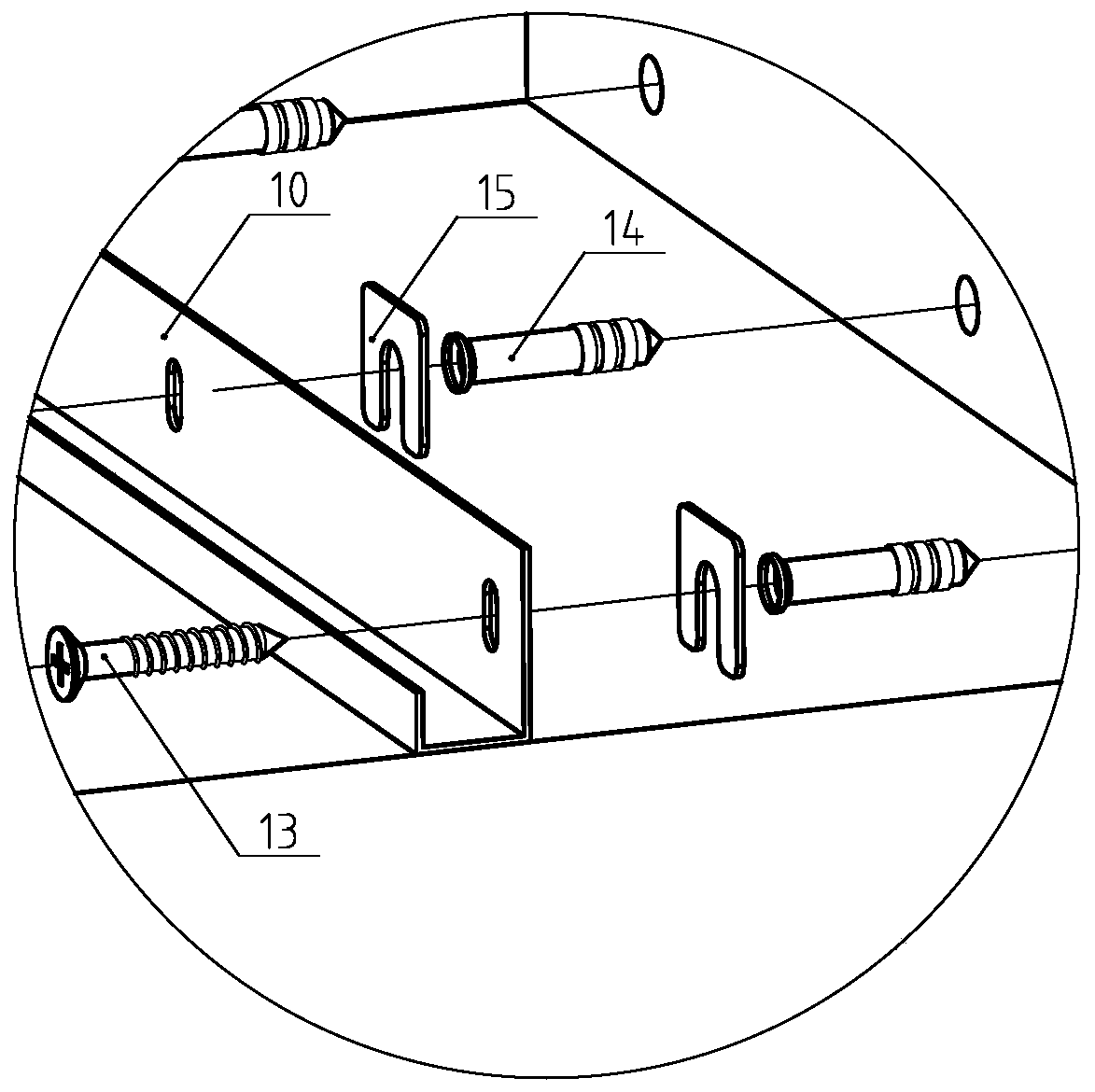

[0084] The laying method disclosed in Embodiment 2 is to drill holes while assembling, which is suitable for laying small-area walls. Embodiment 2 is to fasten the first bead 10 in Embodiment 1 to the ground 1, and set the For fastening the expansion casing of the first bead 10, the laying method includes the following steps:

[0085] d1. Place the auxiliary line. Place the auxiliary line on the ground 1 so that the wall covering board is laid along the auxiliary line. The auxiliary line can be placed on the ground 1 by means of the ink fountain.

[0086] d2. place the first bead 10, adjust the first bead 10, make the first panel 16 of the first bead 10 close to the ground 1, make the second panel 17 of the first bead 10 cooperate with the wall surface 2, the first bead 10 The third panel 18 is in close contact with the auxiliary line. The laying method disclosed in the present invention can be carried out on the blank surface. Since the blank surface has not been leveled, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com