UV coating material and edge sealing process thereof

A coating and pigment technology, applied in the field of UV coating and its edge sealing technology, can solve problems such as affecting human health, easy to breed bacteria, slow construction speed, etc. The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

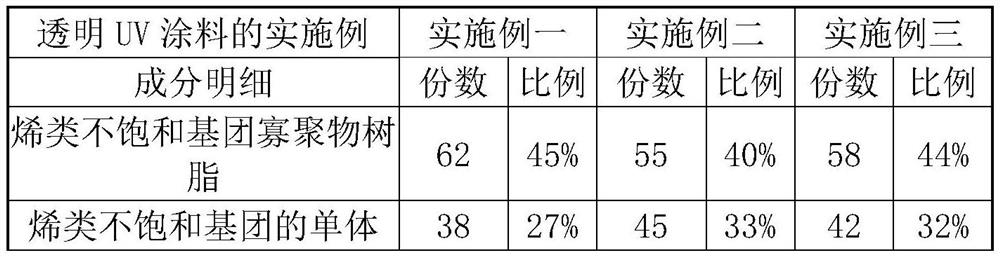

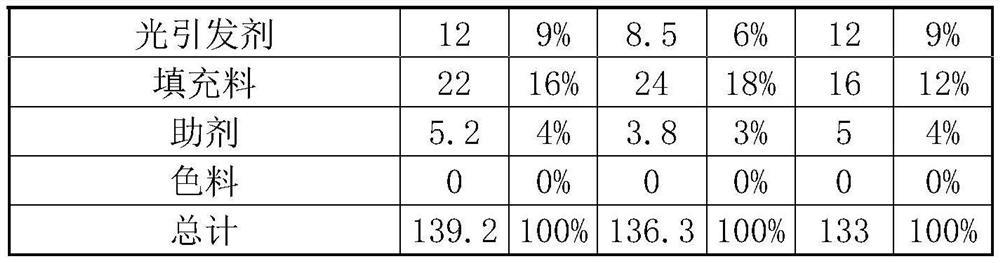

[0041] Specific examples are shown in the following table:

[0042]

[0043]

[0044] Preferably, the ethylenically unsaturated group oligomer resin is an epoxy acrylate oligomer with 1-6 acrylic groups, a polyester acrylate oligomer, a polyurethane acrylate oligomer, A mixture of one or more of modified epoxy acrylate oligomers, amino acrylate oligomers, silicone-modified acrylate oligomers, and fluorine-modified acrylate oligomers.

[0045] Preferably, the ethylenically unsaturated group monomer is isooctyl acrylate, hydroxyethyl methacrylate, hydroxyethyl acrylate, dipropylene glycol acrylate, tripropylene glycol diacrylate with 1 to 6 acrylate groups. ester, 1,6-hexanediol diacrylate, trimethylolpropane triacrylate, glycerol trihydroxypropyl ether triacrylate, trimethylolpropane trimethacrylate, pentaerythritol triacrylate, dipentaerythritol A mixture of one or more of the above five acrylates.

[0046] Preferably, the photoinitiator is 2-hydroxy-2-methyl-1-phenyl-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com