Method and system for producing cyclohexanone from phenol

A technology for cyclohexanone and phenol, applied in the field of phenol production of cyclohexanone, can solve the problems of generating cyclohexanol by-products and the like, and achieve the effects of high conversion rate and yield, reducing side reactions and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

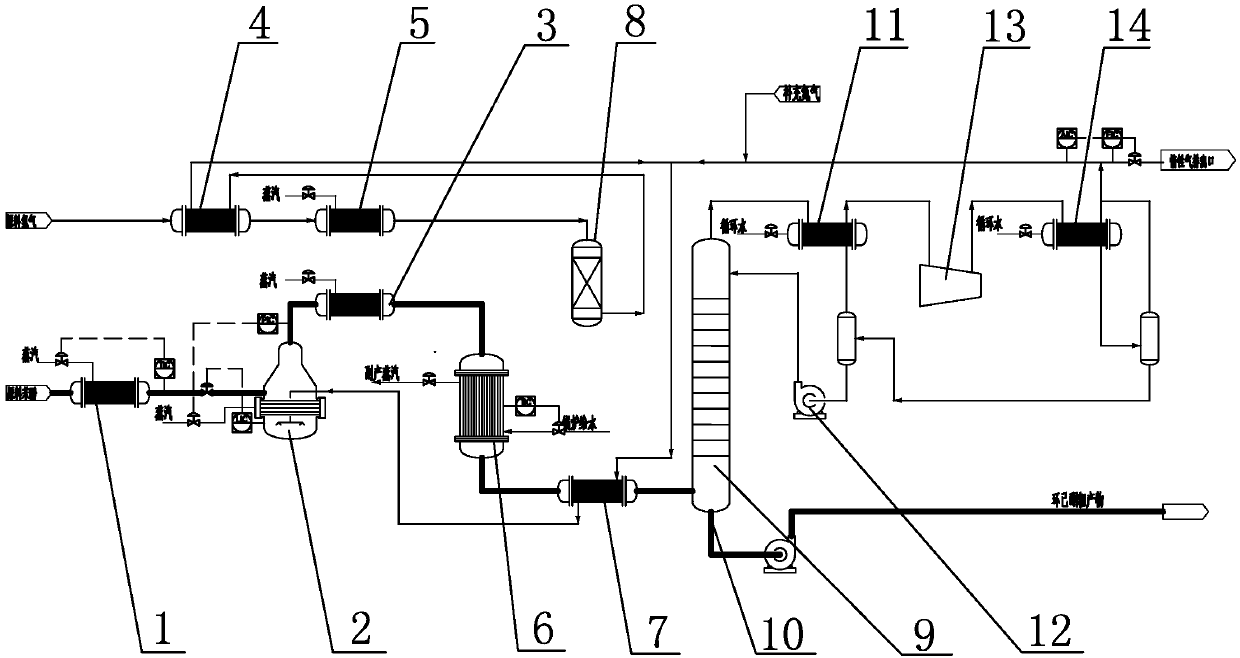

[0038] A method for producing pimelinketone from phenol, such as figure 1 shown, including the following steps:

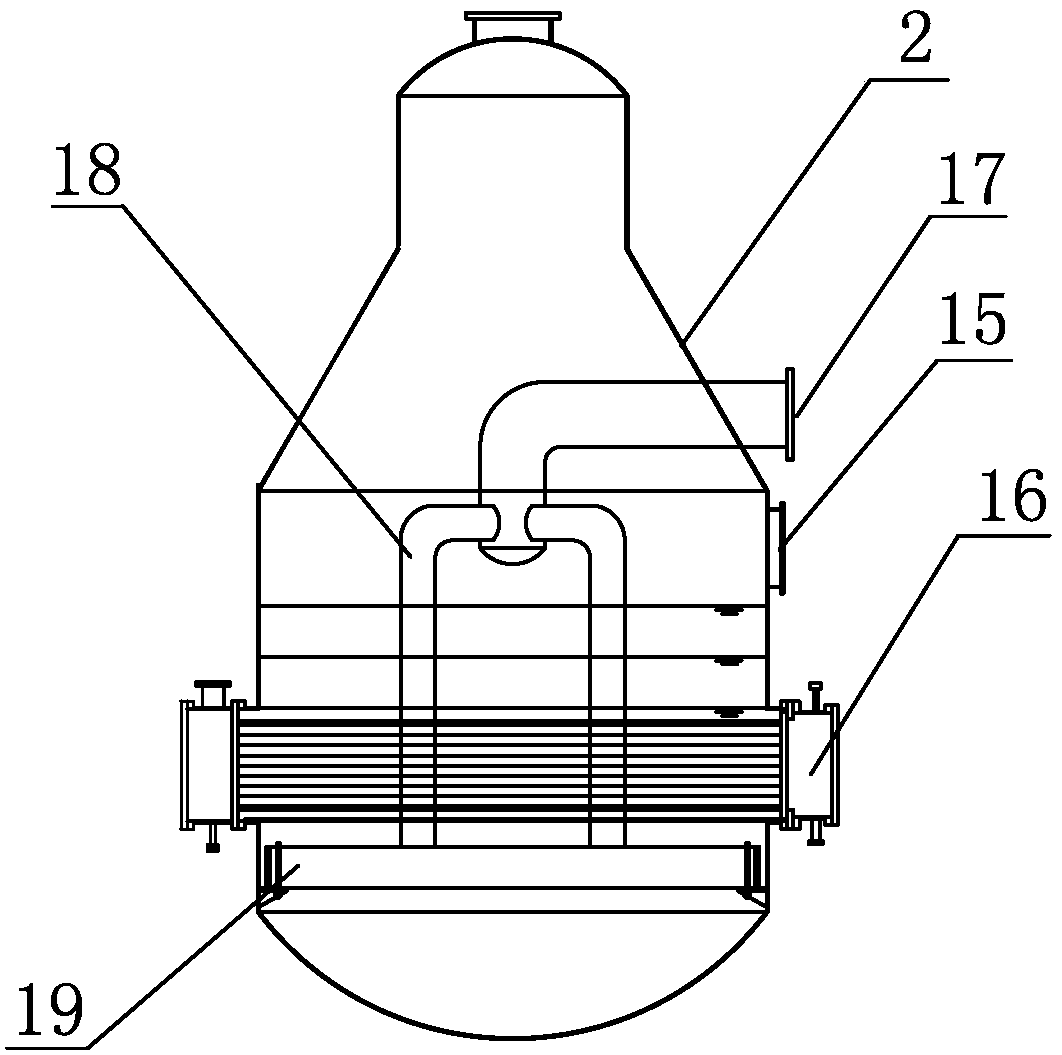

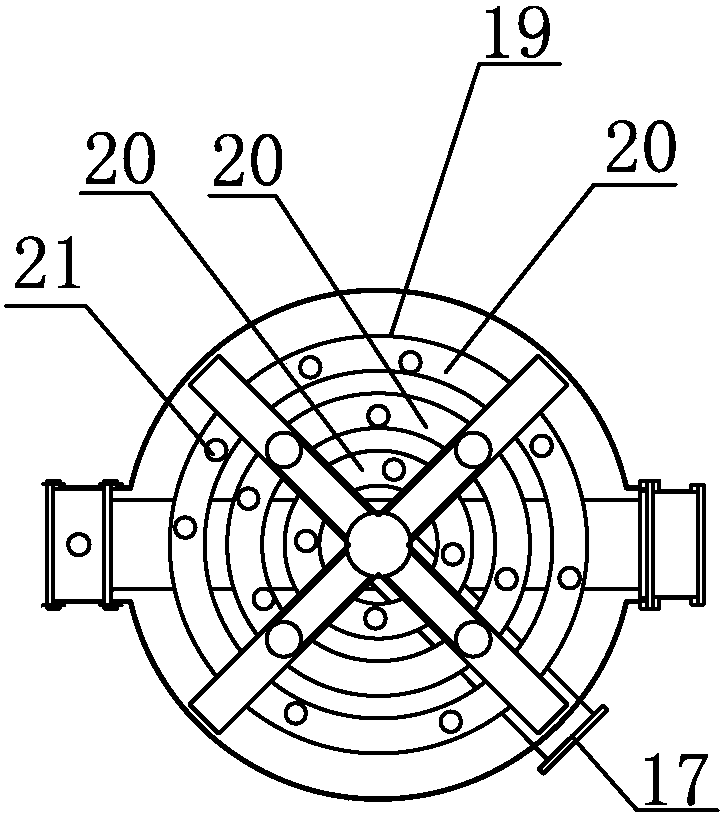

[0039] (1) The raw material phenol is heated to 130°C by the phenol preheater 1 and sent to the phenol vaporizer 2. In the phenol vaporizer 2, the top pressure of the phenol vaporizer 2 is controlled to 0.22MPaG, and the phenol is double-heated by decarbonized hydrogen partial pressure and steam. Function, phenol is vaporized into gas and mixed with decarburized hydrogen and sent to the raw material superheater 3. In the raw material superheater 3, the gas mixture composed of phenol and decarburized hydrogen is superheated to 185°C and then sent to the hydrogenation reactor 6, controlled The mol ratio of phenol and hydrogen in the gas mixture entering hydrogenation reactor 6 is 1:5; the mol ratio of hydrogen and nitrogen in the gas mixture entering hydrogenation reactor 6 is controlled to be 3:1;

[0040] (2) Control the temperature of the reaction material in the...

specific Embodiment 2

[0050] With above-mentioned embodiment 1, its difference is:

[0051] In step (1), the raw material phenol is heated to 120°C through the phenol preheater 1; the top pressure of the phenol vaporizer 2 is controlled to be 0.20MPaG; the gas mixture composed of phenol and decarburized hydrogen is superheated to 175 ℃; the molar ratio of phenol to hydrogen is 1:2, and the molar ratio of hydrogen to nitrogen is 5:1; during the preparation process of decarburized hydrogen: the raw material hydrogen with carbon oxide content of 20ppm is preheated by hydrogen preheater 4 After heating to 160°C, it is heated to 230°C by the hydrogen heater 5 and sent to the decarburization reactor 8; the decarburization reaction temperature is controlled at 235°C, and the pressure is controlled at 1.1MPaG.

[0052] In step (2), the temperature of the reaction material in the hydrogenation reactor 6 is controlled at 195° C., and the pressure is controlled at 0.1 MPaG.

[0053] In step (3), the hydrogen...

specific Embodiment 3

[0059] With above-mentioned embodiment 1, its difference is:

[0060] In step (1), the raw material phenol is heated to 140°C through phenol preheater 1; the top pressure of phenol vaporizer 2 is controlled to 0.25 MPaG; the gas mixture composed of phenol and decarburized hydrogen is superheated to 195 ℃; the molar ratio of phenol to hydrogen is 1:6, and the molar ratio of hydrogen to nitrogen is 2:1; wherein in the preparation process of decarburized hydrogen: the raw material hydrogen with carbon content of 30ppm is preheated to After 170°C, it is heated to 240°C by the hydrogen heater 5 and sent to the decarburization reactor 8; the decarburization reaction temperature is controlled at 245°C, and the pressure is controlled at 1.3MPaG.

[0061] In step (2), the temperature of the reaction material in the hydrogenation reactor 6 is controlled to be 180° C., and the pressure is controlled to be 0.2 MPaG.

[0062] In step (3), the hydrogenation reaction product is heat-exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com