Optimized reaction technology producing ethylene-glycol by adding hydrogen in oxalate

A technology of oxalate ester and ethylene glycol, which is applied in organic chemistry, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of increased equipment investment, complex processing equipment process, large heat load of air cooler, etc., and achieve equipment saving The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

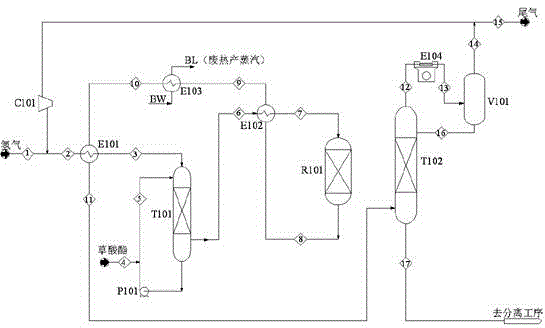

[0030] Charge 4 L of Cu / SiO in the middle of the hydrogenation reactor 2 Catalyst, both ends of the reactor are equipped with fillers of the same particle size as the catalyst, such as porcelain rings, diethyl oxalate is used as the raw material, the hydrogenation reaction temperature is 220 ° C, and the reaction pressure is 3.0 MPa (gauge pressure).

[0031] The system fills in hydrogen 1 with a flow rate of 1.3 Nm 3 / h, the temperature is 60°C, the pressure is 3.2MPa, after mixing with the recycle gas, 2 passes through the heat exchange of E101 to reach 139°C, and enters from the top of the T101 vaporization tower.

[0032] The raw material diethyl oxalate 4 added to the system has a flow rate of 2kg / h, a pressure of 3.05MPa, and a temperature of 139.0°C. It is mixed with the oxalate ester circulating in the vaporization tower tank and then mixed with the mixed gas and flows into the vaporizer for vaporization.

[0033] The mixed gas 6 flow rate from the vaporizer is 42.5Nm ...

Embodiment 2

[0035] Charge 4 L of Cu / SiO in the middle of the hydrogenation reactor 2 Catalyst, the two ends of the reactor are equipped with fillers of the same particle size as the catalyst, such as porcelain rings, diethyl oxalate is used as the raw material, the hydrogenation reaction temperature is 210 ° C, and the reaction pressure is 2.51 MPa (gauge pressure).

[0036] The system fills in hydrogen 1 with a flow rate of 1.27 Nm 3 / h, the temperature is 83°C, the pressure is 2.53MPa, after being mixed with the recycle gas, 2 passes through the E101 heat exchange to reach 140.0°C, and enters from the top of the T101 vaporization tower.

[0037] The raw material diethyl oxalate 4 fed into the system has a flow rate of 2.0kg / h, a pressure of 2.53MPa, and a temperature of 140.0°C. After mixing with the oxalate ester circulated in the vaporization tower, 5 and the mixed gas 3 flow into the vaporization tower for vaporization.

[0038] The flow rate of mixed gas 6 coming out of the vaporiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com