Method for producing deoxygenated water with low-temperature heat as heat source and negative-pressure thermal deaerator system with low-temperature heat as heat source

A low-temperature heat and deaerator technology, applied in chemical instruments and methods, heating water/sewage treatment, water/sewage treatment, etc., can solve fuel consumption, increase refining and chemical enterprise operating costs, energy consumption and pollutant discharge, etc. problems, achieve the effect of reducing energy consumption, saving steam consumption, and improving liquid-vapor mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

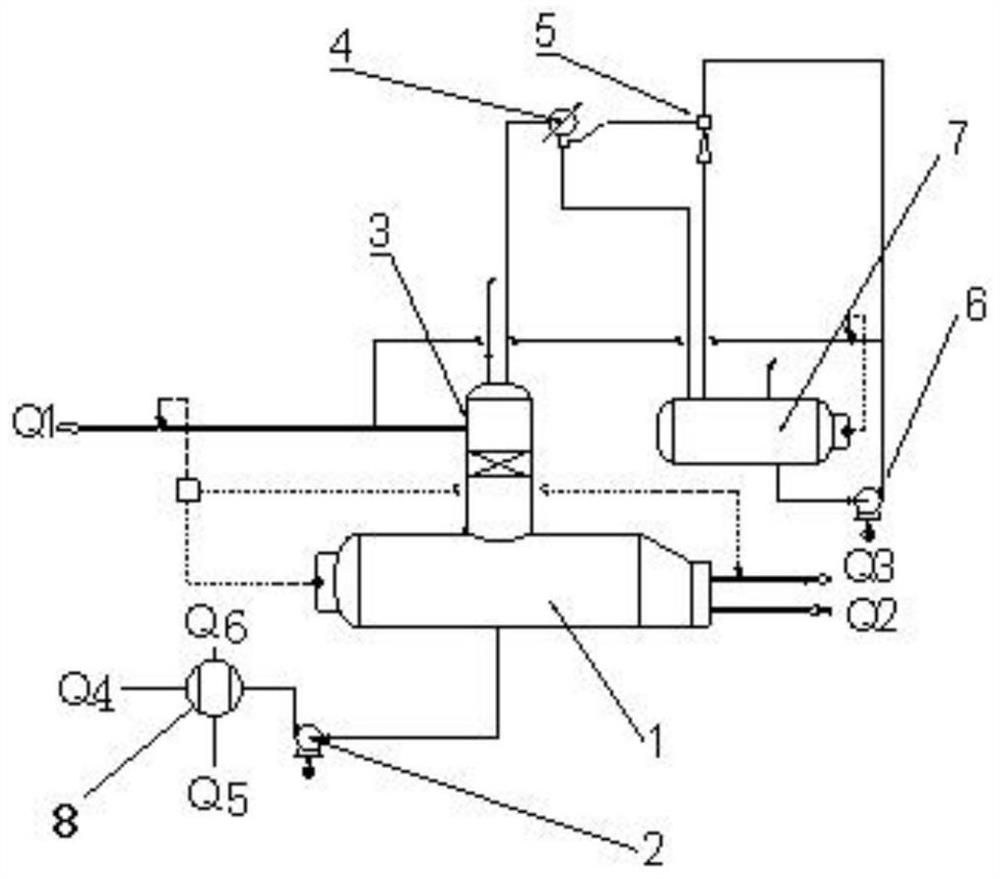

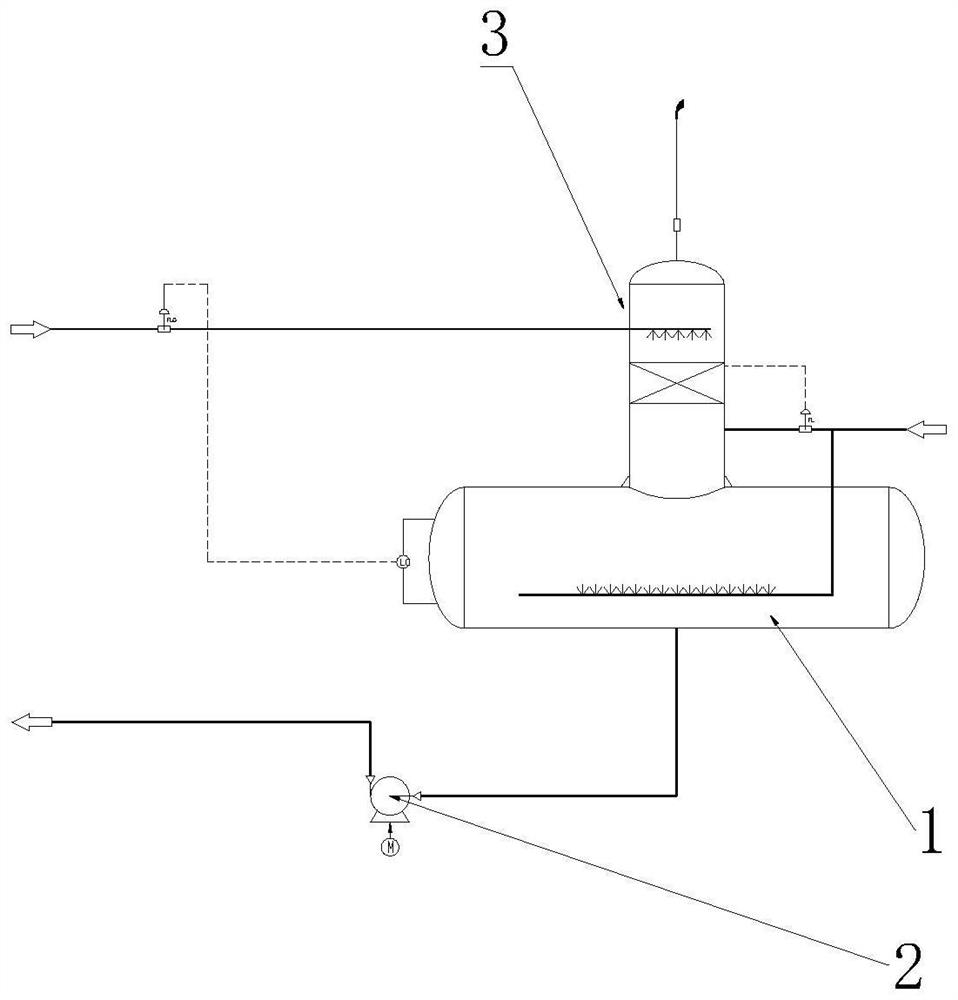

[0105] according to figure 1 The schematic diagram of the negative pressure thermal oxygen removal system with low temperature heat as the heat source is shown. When the output of oxygenated water is small, the steam generator 1 and a stripper 3 are combined into one structure, and the vacuum device 5 is a first-level hydraulic Evacuator, the side of the stripper 3 is connected to the desalted water pipeline Q1, and the gas outlet on the top surface of the stripper 3 is communicated with the tower top condenser 4, and the tower top condenser 4 is connected with the hydraulic evacuator; the steam The deoxygenated water outlet of the generator 1 is connected to the deoxygenated water pump 2, and the deoxygenated water pump 2 is connected to the deoxygenated water-low temperature heat exchanger 8, and the deoxygenated water after pressurization and heat exchange is sent to the downstream steam generating device. One end of the low-temperature heat medium heat exchange tube bundle...

Embodiment 2

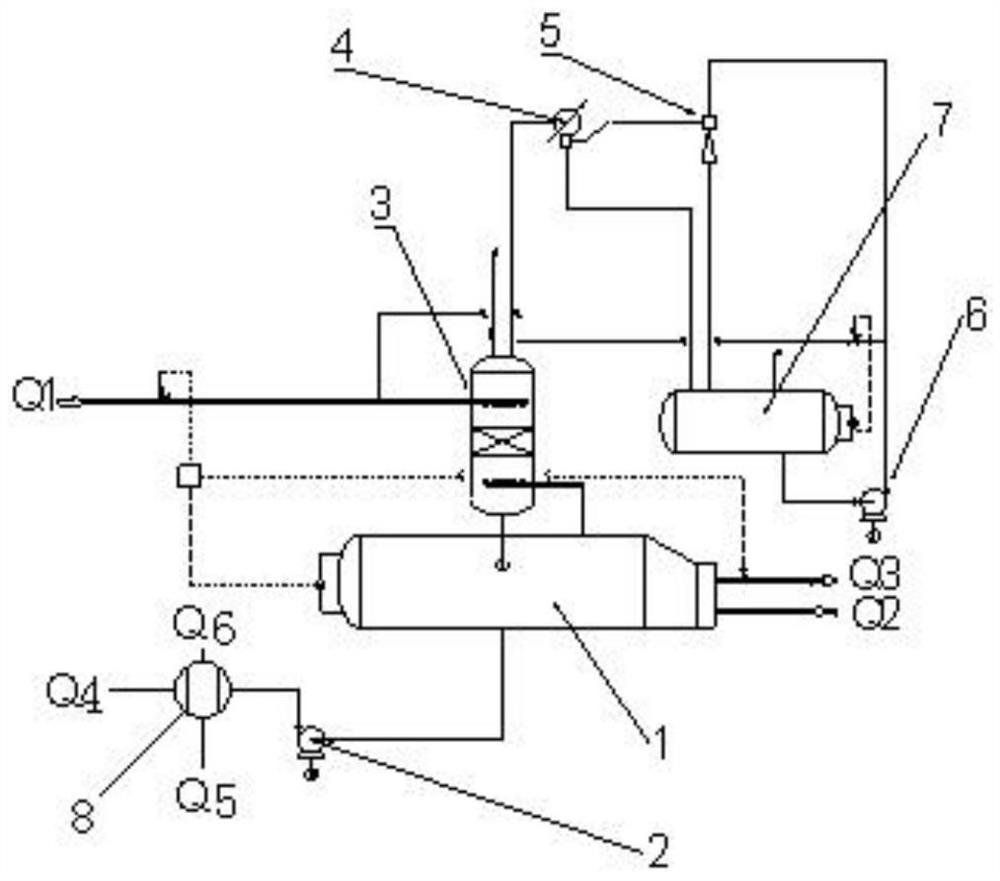

[0108] according to figure 2 The schematic diagram of the negative pressure thermal oxygen removal system using low-temperature heat as the heat source is basically the same as that of Example 1, except that when the equipment is large in size and its layout is limited by the installation space, steam generators 1 and 1 Two strippers 3 are combined into a split structure, the deoxygenated water outlet of the stripper 3 is communicated with the deoxygenated water inlet of the steam generator 1, and the steam inlet of the stripper 3 is connected with the steam generator The steam outlet of device 1 is connected.

[0109] In the present invention, the functions of the steam generator are as follows: 1. Use low-temperature heat to generate steam as a stripping medium; 2. The process of water vaporization on the heat exchange tube further strengthens the oxygen removal effect.

[0110] In the present invention, the operating pressure of the steam generator 1 determines the vapori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com