Method for extracting lactic acid from fermentation liquor through combination of molecular distillation and extraction

A technology of molecular distillation and fermented liquid, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., to achieve the effects of saving resources, strong extraction ability and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

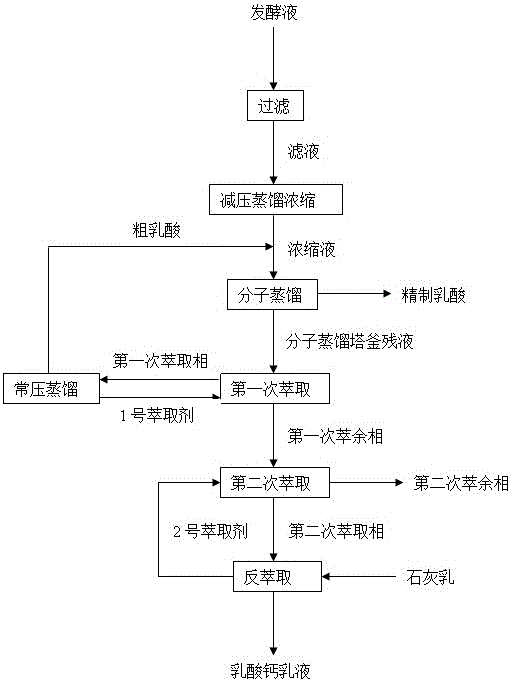

Image

Examples

Embodiment 1

[0013] The sterilized fermented liquid is filtered to remove solid impurities to obtain a filtrate; the filtrate is subjected to vacuum distillation to remove low boilers and part of the water to obtain a concentrated liquid, and the mass fraction of lactic acid in the concentrated liquid is 50%; the concentrated liquid is subjected to molecular distillation to obtain refined lactic acid and Molecular distillation tower residue; the mass ratio of isopropyl ether and isopropyl acetate is a mixture of 1:1 as the No. 1 extractant, and the molecular distillation tower residue is extracted for the first time using No. 1 extractant. The volume ratio of extractant and molecular distillation tower still raffinate is 5:1, obtains upper phase and lower phase, and upper phase is the extraction phase for the first time, and lower phase is the raffinate phase for the first time; pressure distillation to obtain the overhead distillate and the residual liquid in the atmospheric distillation t...

Embodiment 2

[0015] The sterilized fermentation broth is filtered to remove solid impurities to obtain a filtrate; the filtrate is subjected to vacuum distillation to remove low boilers and part of the water to obtain a concentrated solution, and the mass fraction of lactic acid in the concentrated solution is 70%; the concentrated solution is subjected to molecular distillation to obtain refined lactic acid and Molecular distillation tower residue; the mass ratio of isopropyl ether and isopropyl acetate is a mixture of 5:1 as the No. 1 extractant, using No. 1 extractant to extract the molecular distillation tower residue for the first time, No. 1 The volume ratio of extractant and molecular distillation column bottom liquid is 10:1, and upper phase and lower phase are obtained, and upper phase is exactly the extraction phase for the first time, and lower phase is the raffinate phase for the first time; pressure distillation to obtain the overhead distillate and the residual liquid in the a...

Embodiment 3

[0017] The sterilized fermented liquid is filtered to remove solid impurities to obtain a filtrate; the filtrate is subjected to vacuum distillation to remove low boilers and part of the water to obtain a concentrated liquid, and the mass fraction of lactic acid in the concentrated liquid is 60%; the concentrated liquid is subjected to molecular distillation to obtain refined lactic acid and Molecular distillation tower residue; the mass ratio of isopropyl ether and isopropyl acetate is a mixture of 3:1 as the No. 1 extractant, using No. 1 extractant to extract the molecular distillation tower residue for the first time, No. 1 The volume ratio of extractant to molecular distillation tower still raffinate is 8:1, and upper phase and lower phase are obtained, and upper phase is the extraction phase for the first time, and lower phase is the raffinate phase for the first time; pressure distillation to obtain the overhead distillate and the residual liquid in the atmospheric distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com