Brine-desalination method

A water desalination and raw water technology, applied in the field of salt water desalination, can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

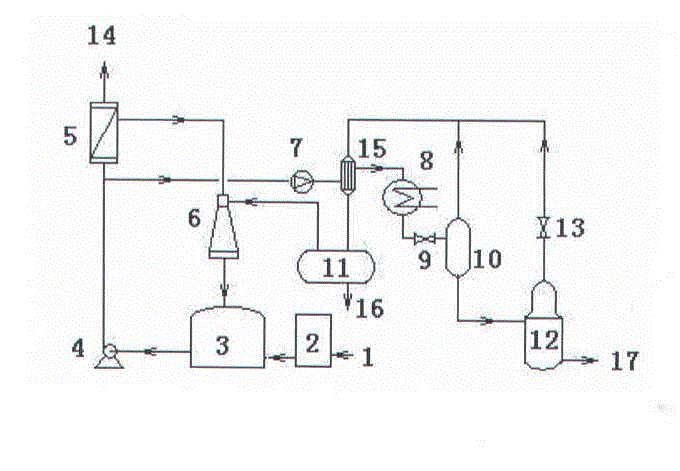

[0016] a. The brine 1 is pretreated by mechanical impurity removal filtration, microfiltration, ultrafiltration, and security filter 2 and then enters the intermediate water tank 3, and then enters the reverse osmosis membrane treatment device 5 through the booster pump 4 for membrane filtration to obtain membrane treatment clean water 14;

[0017] b. The purified water 14 treated by the membrane can be stored or put into use. The remaining concentrated brine is discharged in two ways, one way enters the Venturi jet pump for high-speed injection, enters the middle water tank 3 for circulation treatment, and the other way passes through the check valve 7 (to prevent pipeline The internal fluid flows backwards), after being heated by the heat exchanger 15 and the heater 8 (the heating device 8 provides heat energy for the evaporation of water vapor, various forms of heating furnaces can be used, and power plants with conditions can use waste heat steam as a heat source, light Su...

Embodiment 2

[0020] The raw water treated in this embodiment is brackish water, which can be used in areas with long sunshine hours.

[0021] a. The brackish water 1 enters the intermediate water tank 3 after being pretreated by mechanical impurity removal filtration, microfiltration, ultrafiltration, and security filter 2, and then enters the reverse osmosis membrane treatment device 5 through the booster pump 4 for membrane filtration to obtain Membrane treatment water purification 14;

[0022] b. The purified water 14 treated by the membrane is stored or put into use, and the remaining concentrated brine is discharged in two ways, one way enters the Venturi jet pump for high-speed injection, enters the middle water tank 3 for circulation treatment, and the other way passes through the check valve 7 (to prevent the water from entering the pipeline) Fluid backflow), after being heated by the heat exchanger 15 and the heater 8 (here is a solar water heater), the throttle valve 9 (plays...

Embodiment 3

[0025] The raw water processed in this embodiment is sea water;

[0026] a. The seawater (1) enters the intermediate water tank (3) after being pretreated by mechanical impurity removal filtration, microfiltration, ultrafiltration, and security filter (2), and then enters the nanofiltration membrane treatment device (5) through the booster pump 4 ) to perform membrane filtration to obtain membrane-treated purified water 14;

[0027] b. The purified water 14 treated by the membrane is put into use, and the remaining concentrated brine is discharged in two ways, one way enters the Venturi jet pump for high-speed injection, enters the middle water tank 3 for circulation treatment, and the other way passes through the check valve 7 to prevent the fluid in the pipeline from backflowing, After being heated by the heat exchanger 15 and the heater 8 (the heating device 8 provides heat energy for the evaporation of water vapor, various forms of heating furnaces can be used, power plant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com