Energy-saving electrothermal tunnel kiln

A technology of tunnel kiln and electric heating, which is applied in the field of energy-saving electric heating tunnel kiln, which can solve the problems that the heat cannot be recovered, prolonging the contact heat transfer time between the heat transfer medium and the surface of the product, and limiting the energy saving of the electric heating tunnel kiln.

Inactive Publication Date: 2011-05-04

袁锐

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the existing technology, in order to improve the heat transfer effect, a fan for stirring the hot air is installed on the roof of the inner kiln to increase the flow rate of the hot air on the surface of the product. Although it is more energy-saving than the original technology, there are still the following technical problems that cannot be solved. One The stirring fan can only make the hot air flow, but it cannot prolong the heat transfer time between the hot air and the surface of the product, because the stacking method of the products on the kiln car in the prior art is different from the previous one, and the products that have not been heat-treated are packaged according to the finished product. The stacking method of cubes is stacked, and the pallets made of wood are placed on the kiln car to simplify the process. In order to meet the same process requirements and save energy, it is necessary to increase the heat evenly to the six sides of the cube products. and prolong the heat transfer time between the heat transfer medium and the surface of the product. The second is that due to intermittent production, the heat taken away by the kiln product after heat treatment cannot be recovered. These two technical defects limit the further energy saving of the electric heating tunnel kiln.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

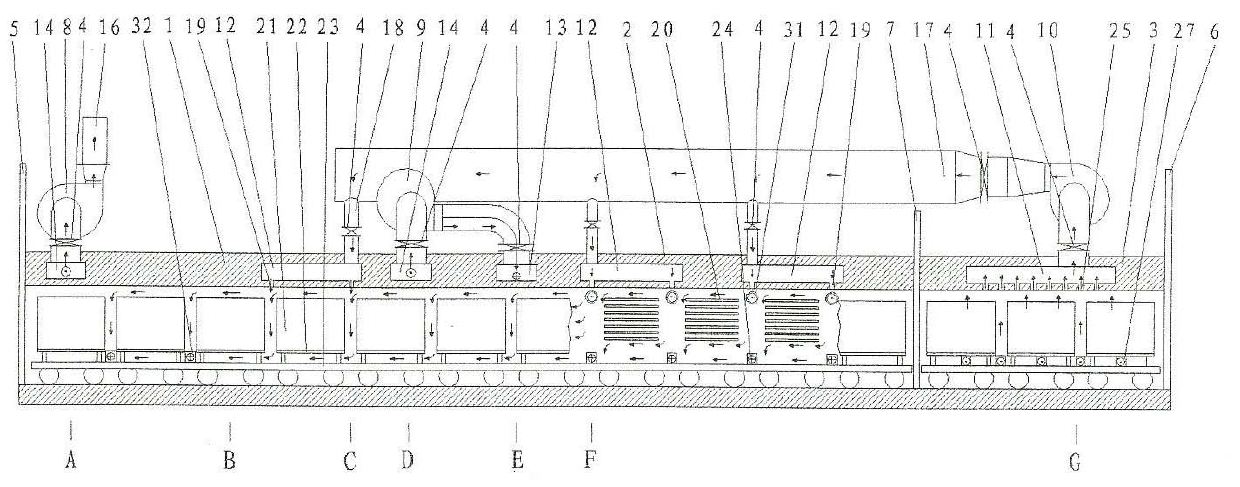

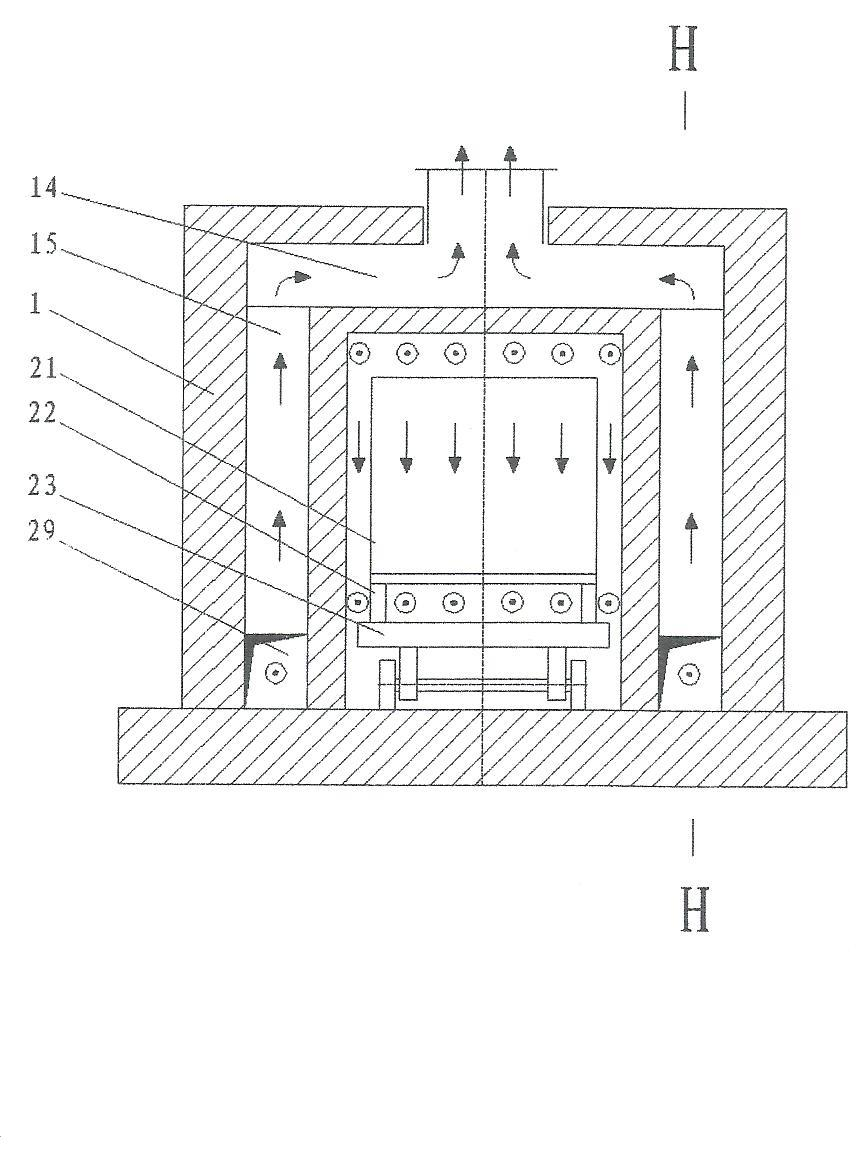

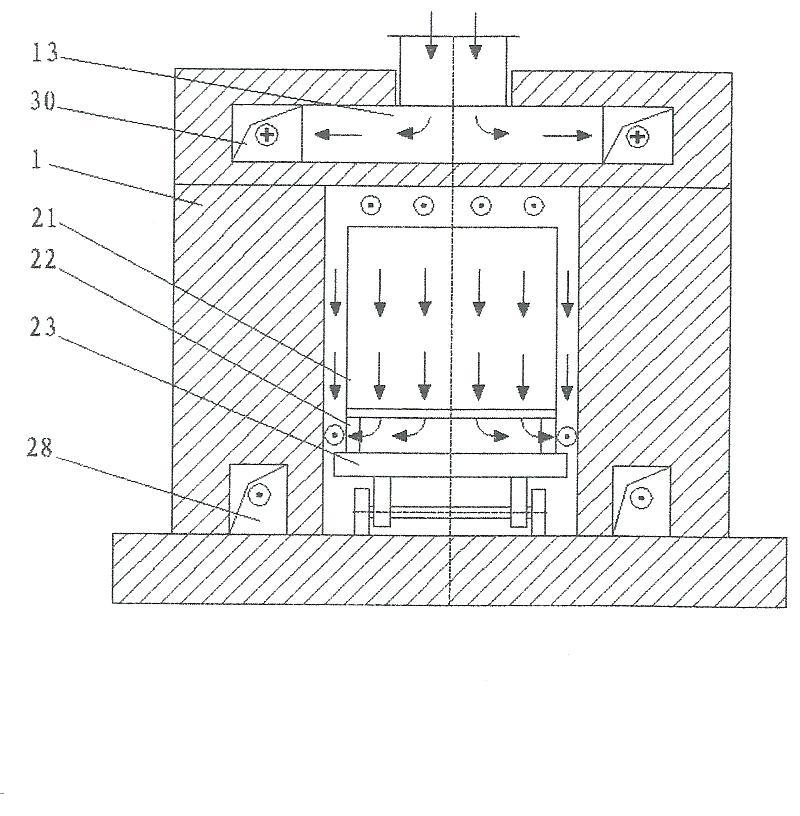

The invention relates to an energy-saving electrothermal tunnel kiln, which is characterized in that: a circulating fan is arranged on the kiln top in a heating and thermal-insulation zone of the tunnel kiln; the air inlet of the circulating fan is connected with a valve, an air suction chamber, an air suction vertical duct, a lower circuiting air duct and a circulating air suction hole in turn; the air outlet of the circulating fan is connected with a valve, a circulating air inlet chamber, an upper circulating air duct and a circulating air spray nozzle in turn; electrical heating elements are arranged besides the sides walls in the kiln in the heating and thermal-insulation zone; a blower is arranged on the kiln top in a cooling zone of the tunnel kiln; and an exhaust fan is arranged on the kiln top in an preheating zone of the tunnel kiln. In the energy-saving electrothermal tunnel kiln, the kiln body is made of a high-quality thermal-insulation material to reduce the radiation loss on the surface of the kiln body, the thermal efficiency is 3 percent lower than that of an intermittent kiln, the after heat of products subjected to heat treatment in the tunnel kiln is recovered to preheat kiln products to raise the temperature of the kiln products by 50 DEG C, and the power saving rate reaches 16 percent.

Description

technical field The invention belongs to an electric heating kiln for heat treatment of refractory products, in particular to an energy-saving electric heating tunnel kiln. Background technique At present, domestic electric kilns used for heat treatment of refractory products are traditionally produced in an intermittent manner. At regular intervals, a row of kiln cars that have completed heat-treated products in the kiln is pulled out, and then pushed into a row of kiln cars that have not yet been heat-treated. The heating and holding temperature is 200~250°C, and the products are heated by electric heating elements installed next to the two walls of the kiln. Because part of the heat emitted by the heating element is transferred to the product by radiation heat transfer, the other part is transferred to the hot air by radiation heat transfer, and the hot air is transferred to the product by convection. In the existing technology, in order to improve the heat transfer eff...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27B9/06F27B9/30F27D17/00

Inventor 袁奕明袁锐

Owner 袁锐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com