Optimal operation method and system for utility boiler based on CO

A power plant boiler, optimized operation technology, applied in the field of boiler systems and thermal power plants, can solve the problems of difficult to obtain uniform mixing of flue gas, unrepresentative oxygen value, large flue cross section, etc., to avoid excessive CO emission concentration. Low, improve economy and safety, reduce the effect of NOX emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

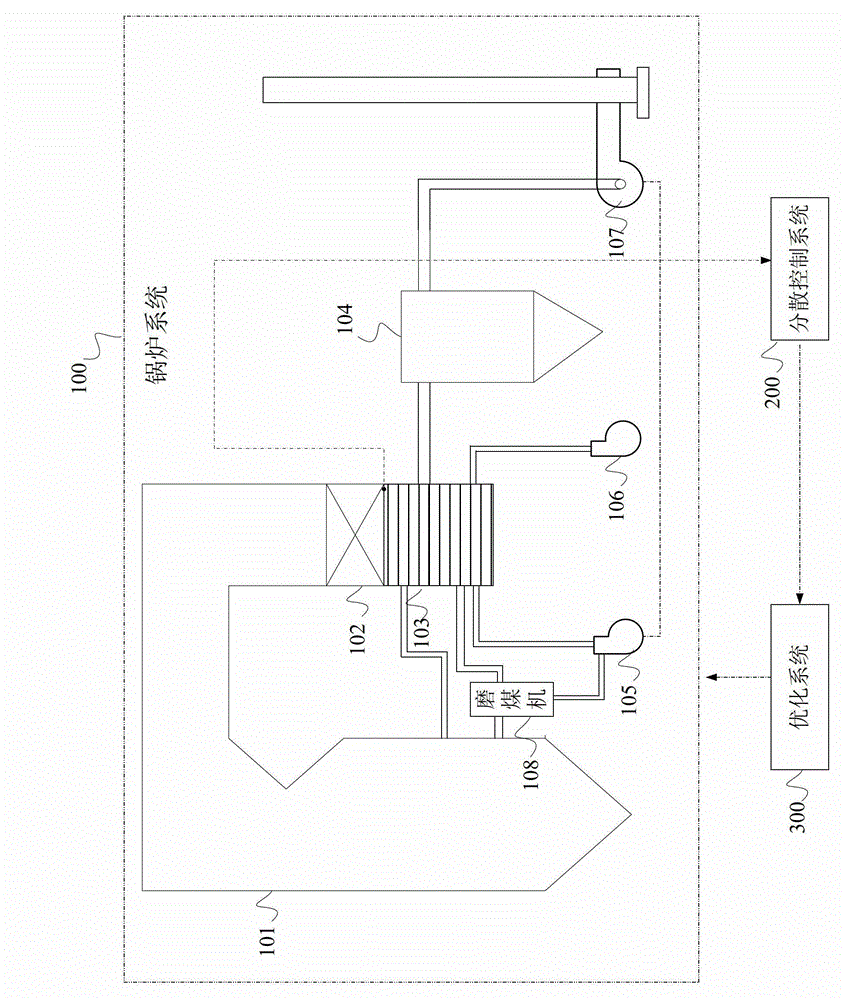

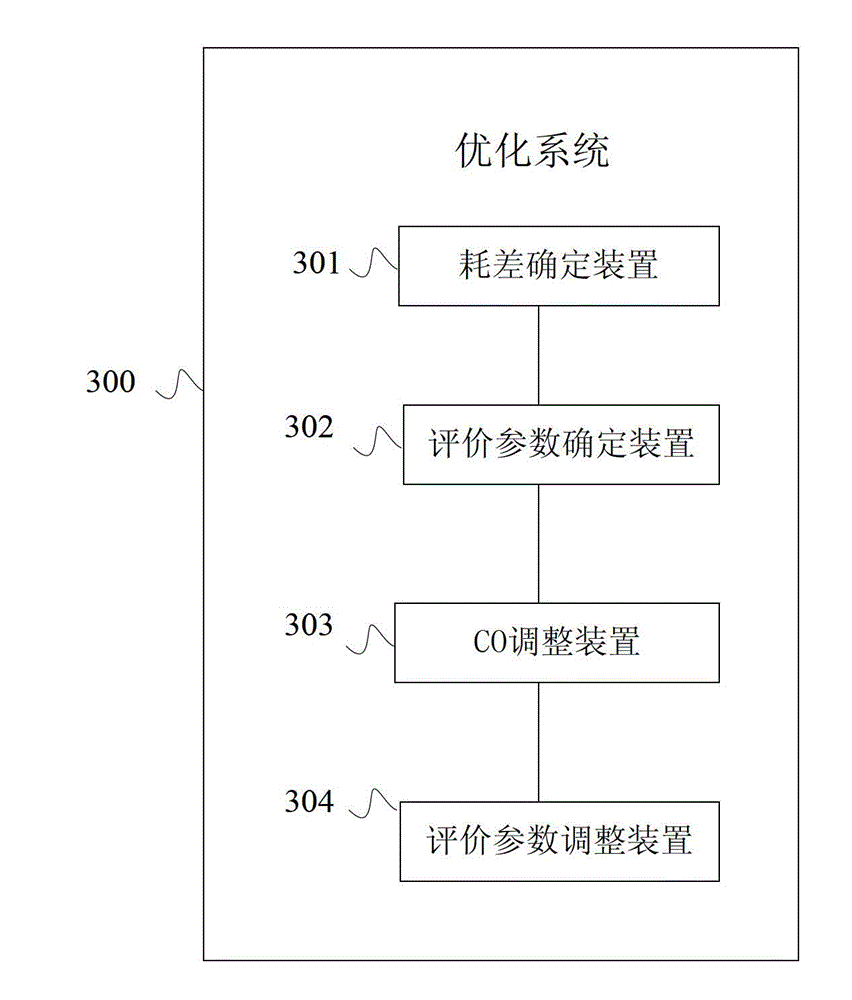

[0021] figure 1 A schematic structural diagram of a CO-based utility boiler optimization operation system provided for the embodiment network of the present invention, consisting of figure 1 It can be known that the system includes: boiler system 100, decentralized control DCS system 200, optimization system 300,

[0022] Wherein, the boiler system includes a furnace 101, an economizer 102, an air preheater 103, a dust collector 104, a primary fan 105, a blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com