Variable-temperature drying device of medium and high temperature heat pump

A high-temperature heat pump and temperature-variable drying technology, which is applied in the direction of drying gas arrangement, drying, and dryers, can solve the problems of thermal efficiency of biological pollution, long drying time and decline of low-temperature heat pumps, so as to improve thermal efficiency and overcome low drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with embodiment.

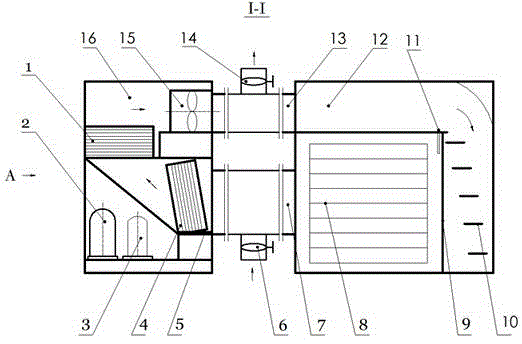

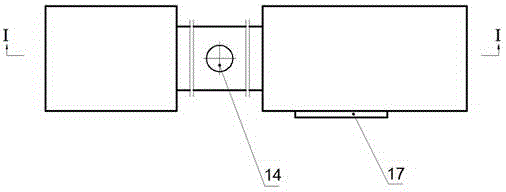

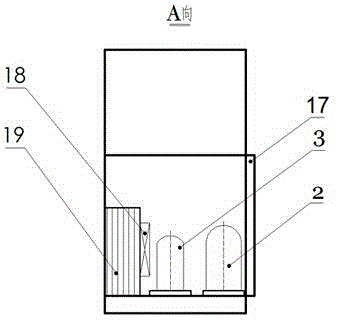

[0024] The present invention consists of a condenser 1, a compressor 2, a liquid storage tank 3, an evaporator 4, a water collecting tray 5, three ventilation pipes with an electric temperature and humidity control air valve 6, an air outlet pipe 7, a material rack 8, and a multi-hole air equalizer. Plate 9, air deflector 10, temperature and humidity sensor 11, drying compartment 12, air inlet pipe 13, three ventilation pipes with electric temperature and humidity control air valve 14, main fan 15, medium and high temperature heat pump box 16, feed door 17. Composed of auxiliary fan 18 and auxiliary condenser 19; the specific connection diagram is attached figure 1 , attached figure 2 And attached image 3 . Condenser 1, evaporator 4, auxiliary condenser 19, compressor 2, liquid storage tank 4, throttle valve, two-way valve are connected by copper pipes and placed in the heat pump box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com