Cooking part device of cocoon cooking machine

A technology of cooking section and cocoon cooking machine, which is applied in mechanical treatment, silk fiber production, textile and papermaking, etc., can solve the problems of damage to the glue point of silk strands, overcooking, uneven temperature of silk cocoons, etc., and achieve the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

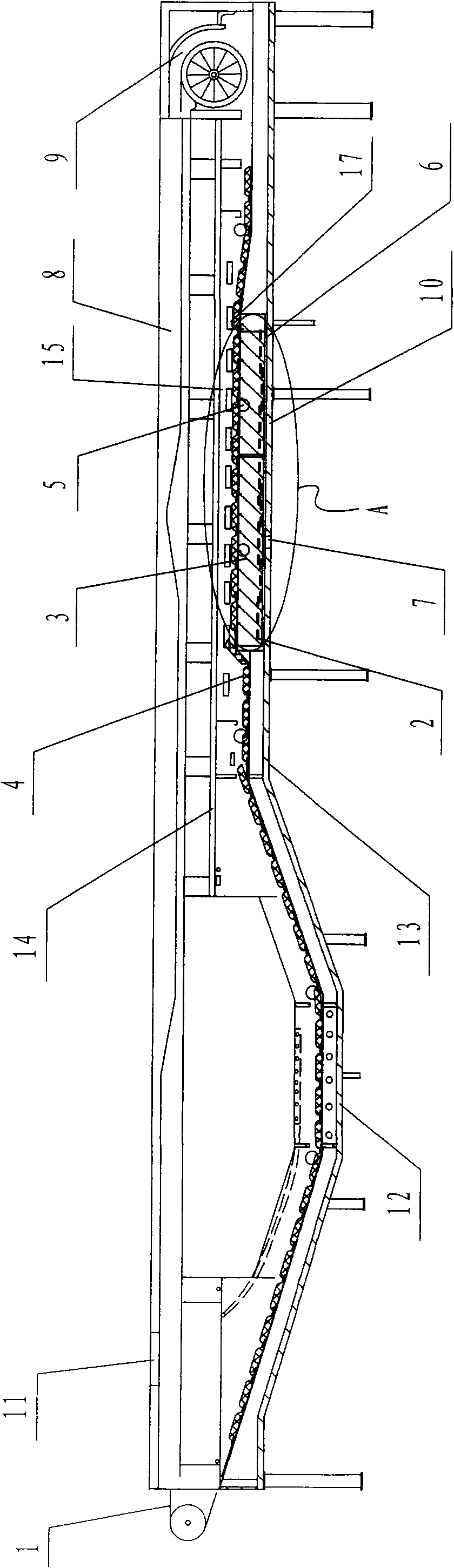

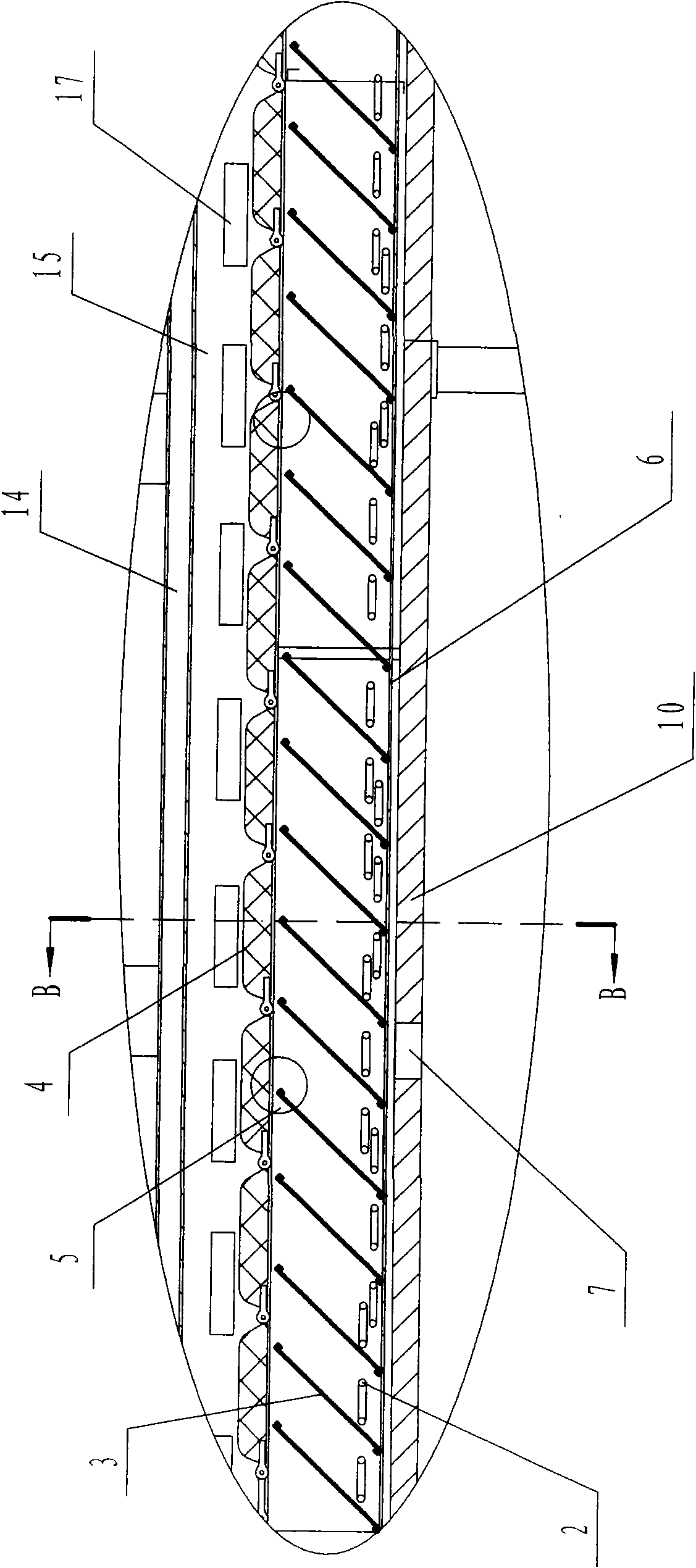

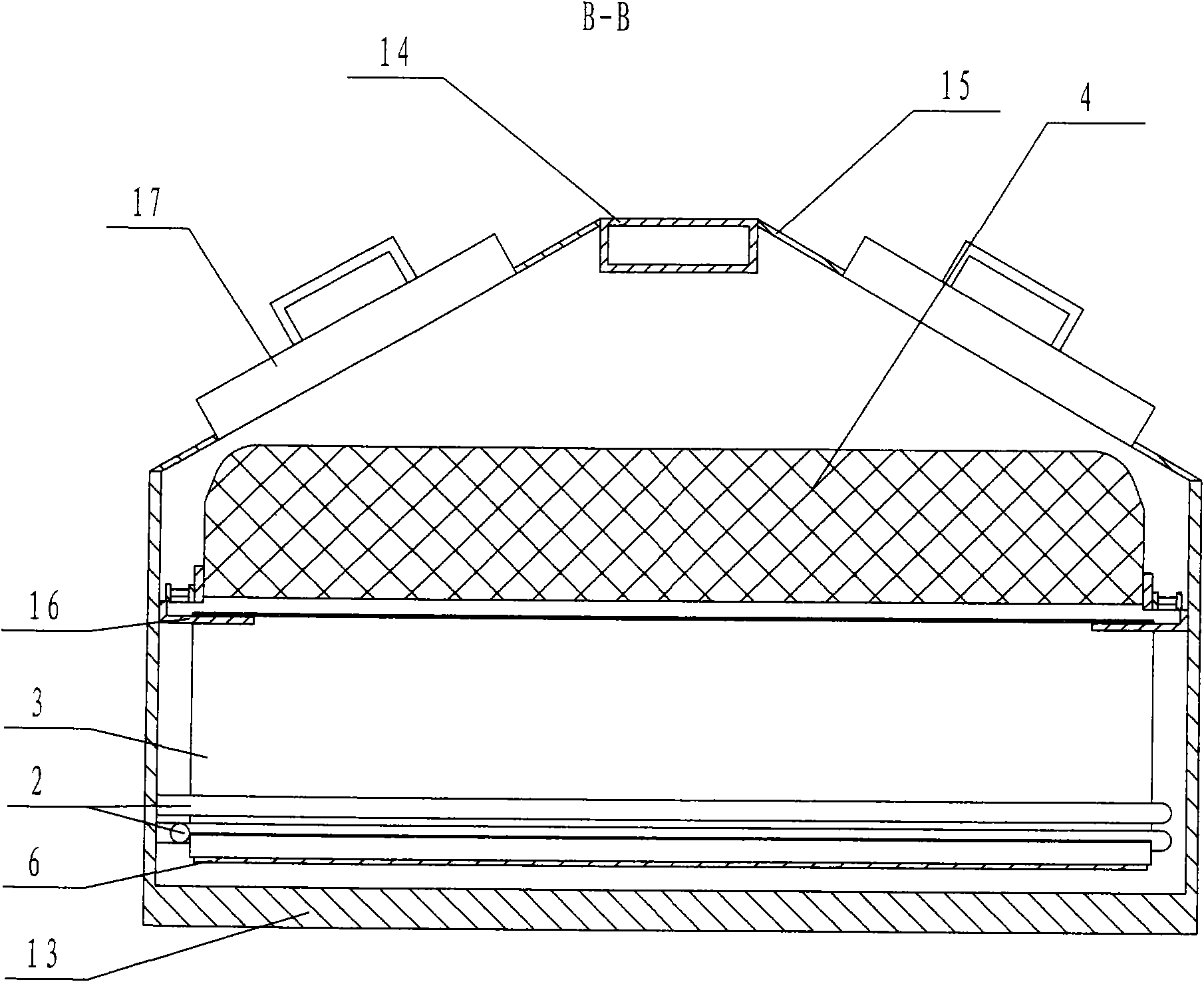

[0017] like figure 1 , figure 2 and image 3 The cooking device of a cocoon cooking machine is shown, which includes a tank body 13, a cooking chamber 10 located in the tank body 13, a beam 14, a reflective plate 6 arranged at the bottom of the cooking chamber 10, and a height of the cooking chamber 10. The steam elbow 2 on the reflecting plate 6, the cover plate 15 connected to the beam 14 at the top of the cooking chamber 10, and the windows 5 arranged on the two straight walls of the cooking chamber 10, the windows 5 are mainly used to observe the inside of the cooking chamber 10 In real time, the beam 14 is located in the middle of the top of the cooking chamber 10 and is connected to the tank body 13, the length of the straight pipe of the steam elbow 2 is less than the width of the reflector 6, and the bottom of the steam elbow 2 is provided with several steam injection holes, the two straight walls of the cooking chamber 10 are provided with several symmetrical hooks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com