Extraction of vanadium and molybdenum compound from refused materials containing vanadium and molybdenum etc. multiple elements

A technology of molybdenum compounds and waste materials, which is applied in the field of comprehensive utilization of waste resources, can solve problems such as lack of treatment plans, and achieve the effect of complete precipitation and stable pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

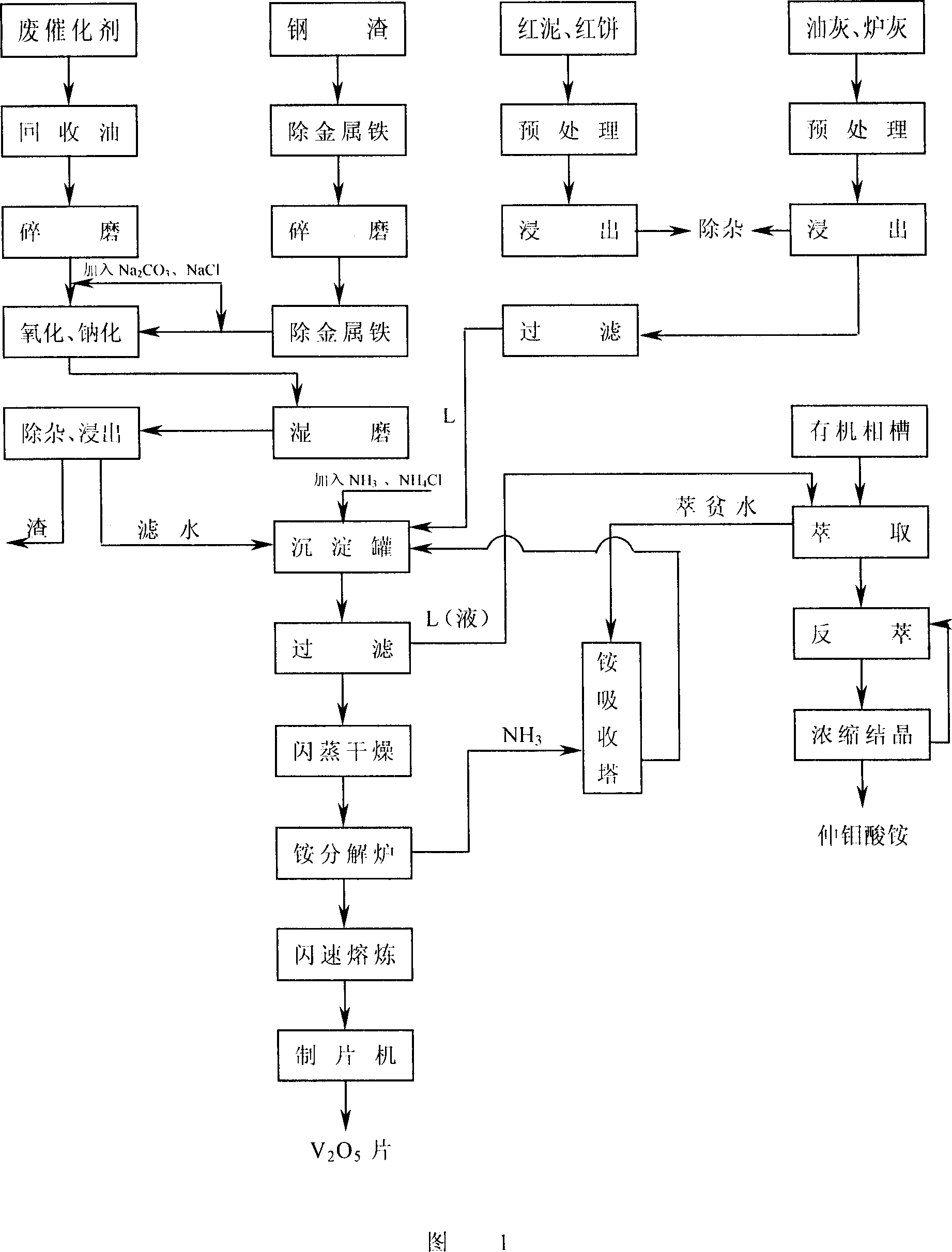

Image

Examples

Embodiment 1

[0068] The actual measurement of the material balance listed in the above table was completed under the conditions of flash drying temperature of 200°C, ammonia decomposition furnace temperature of 500°C and flash furnace temperature of 700°C.

[0069] The above examples are the results of three groups of material balance measurements. With this three-step vanadium production method, not only the product recovery rate is as high as 99%, but the finished vanadium is increased by 6-7 percentage points, and the unit oil consumption is also lower than that of the reverberatory furnace refining flake vanadium. A ton of fuel oil.

[0070] The production of vanadium pentoxide from vanadium-containing wastes does not pay attention to the recovery of decomposed ammonia and water ammonium in the formulation of processes at home and abroad. The method adopted is to further decompose most of the decomposed ammonia into H 2 and N 2 A small part of high-altitude emissions. The pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com