Offshore platform thermal recovery fuel oil or fuel gas steam injection boiler

An offshore platform and steam injection boiler technology, which is applied in steam boilers, water-tube steam boilers, preheating, etc., can solve the problems of large floor space and inability to meet the needs of offshore platforms for oil extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing:

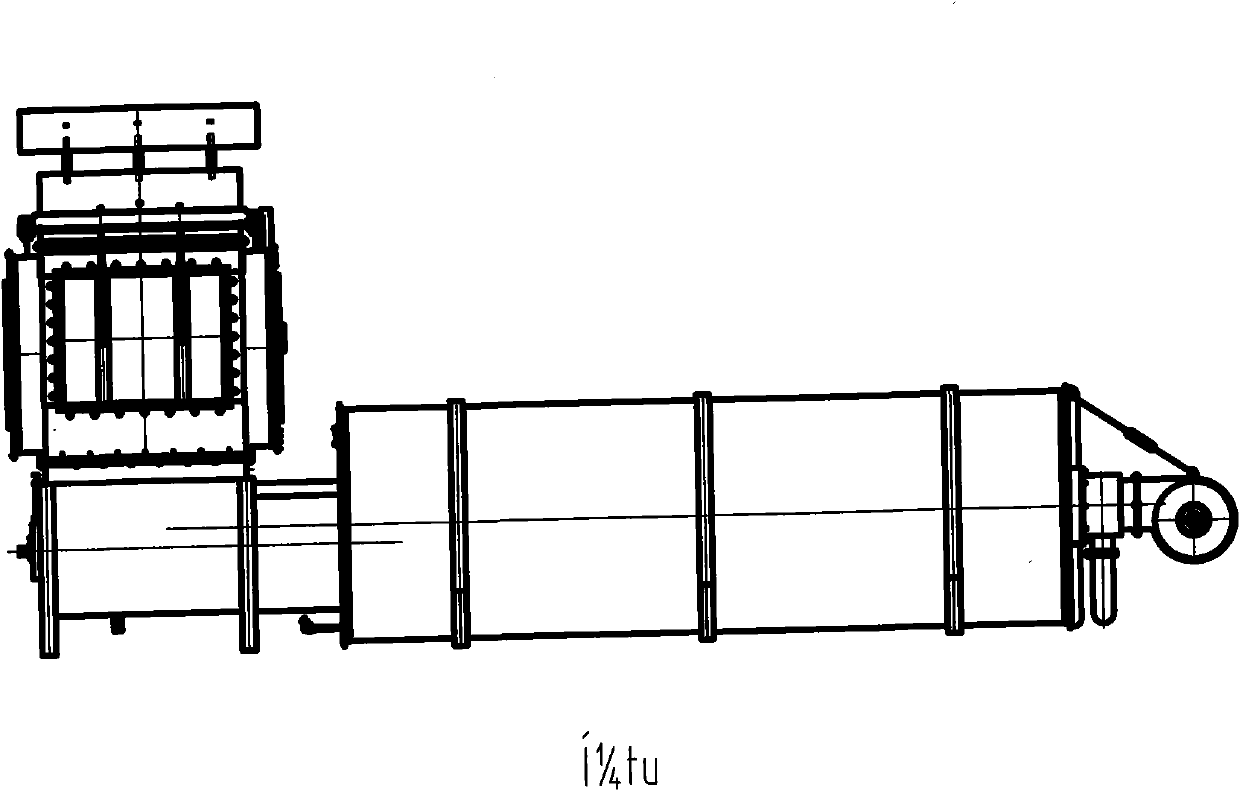

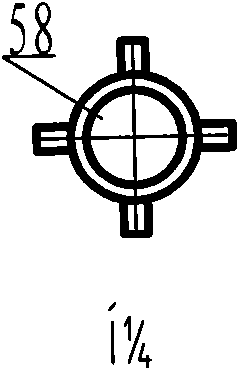

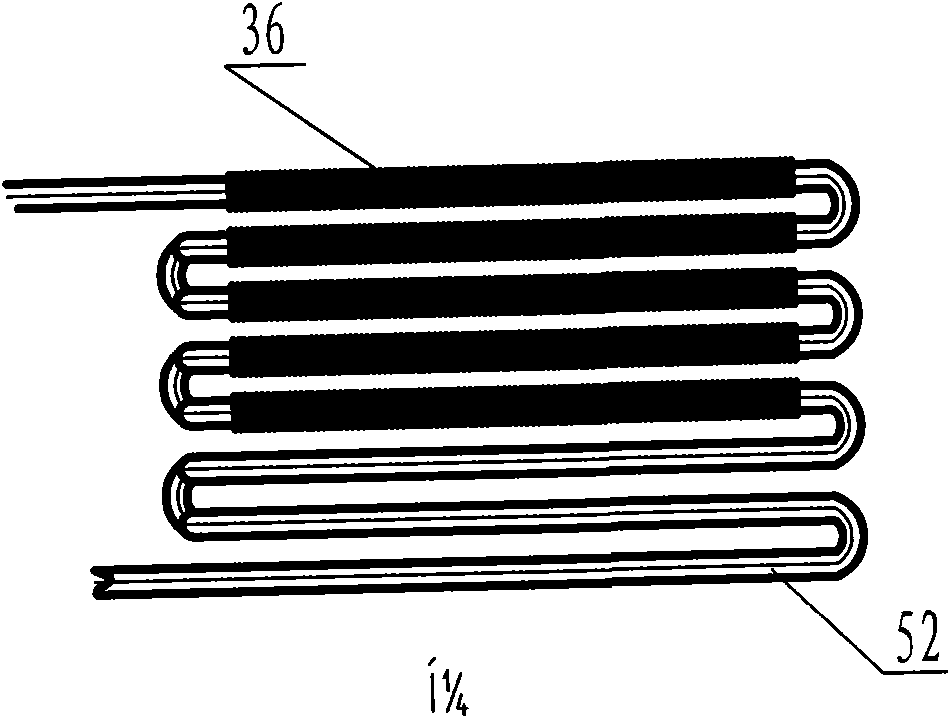

[0046] attached by figure 1 to attach Figure 26 As shown, the oil-fired oil or gas-fired steam injection boiler on the offshore platform mainly includes two parts of the boiler body and auxiliary equipment and connecting pipelines. The boiler body is the skeleton of the steam injection boiler and mainly includes the radiation section 2 1 and water heat exchanger 3; the auxiliary equipment mentioned is the necessary auxiliary equipment to ensure the normal operation of the boiler body, mainly including the steam-water system, the ventilation system, the combustion system and the automatic control system, and also includes the steam boiler connected between the systems. water line.

[0047] The radiant section 2 mainly includes a furnace wall 43 lined with an insulating layer and a tube bundle 34 inside the furnace wall, which is the main heating surface of the steam injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com