Process for pretreatment of coke oven gas and partial oxidation preparation of synthetic raw gas

A process method and technology of coke oven gas, which is applied in the chemical modification of combustible gas, purification/transformation of combustible gas, petroleum industry, etc., to achieve the effects of low investment, sufficient heat utilization and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

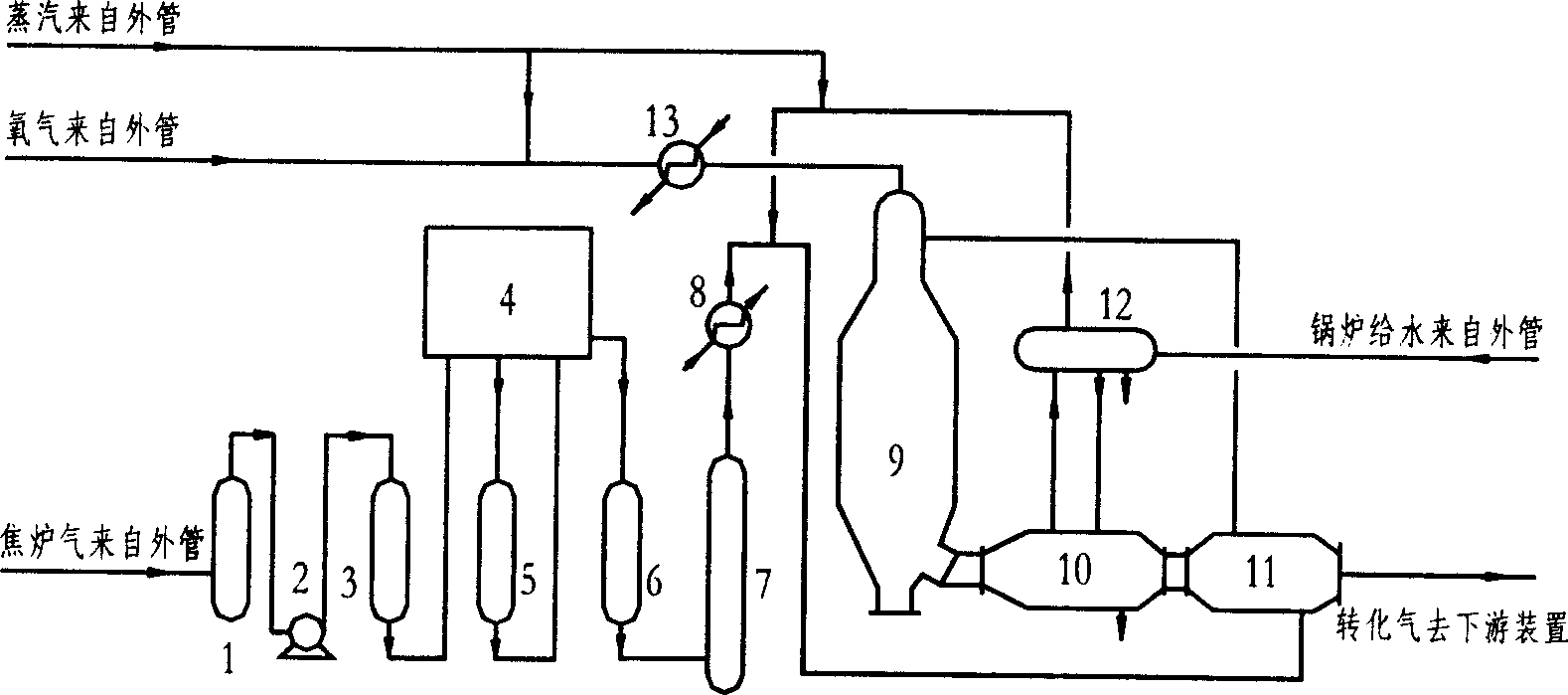

[0030] The process flow and main parameters of the 350,000-ton ammonia synthesis plant designed by the present invention using coke oven gas as raw material.

[0031] Process description:

[0032] 1. Electric tar capture: The coke oven gas from the boundary area passes through the electric tar capture device 1 to remove the tar in the coke oven gas to less than 0.2PPM

[0033] 2. Naphthalene removal from coke oven gas: the coke oven gas after electric tar removal is boosted to 1.3bar by blower 2, and the temperature is 40°C. The gas is compressed to 3.1bar (bar) by the feed gas compressor 4 in one stage, and the coke oven gas with a temperature of 160±10°C enters the fine naphthalene removal tank 5 after heat exchange, and the naphthalene in the coke oven gas after two-stage naphthalene removal is reduced to 60 mg / Nm 3 When it drops below 0.1PPm, the coke oven gas is cooled to normal temperature and then returns to the raw gas compressor 4.

[0034] 3. Deoxidation and desul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com