Suspension type automatic blanking vertical and horizontal dual-purpose heat accumulation energy-saving reduction furnace

A vertical and horizontal dual-purpose reduction furnace technology, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of high energy consumption, thermal creep deformation and scrapping of reduction tanks, low production efficiency, etc. Furnace structure, high labor intensity of workers, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

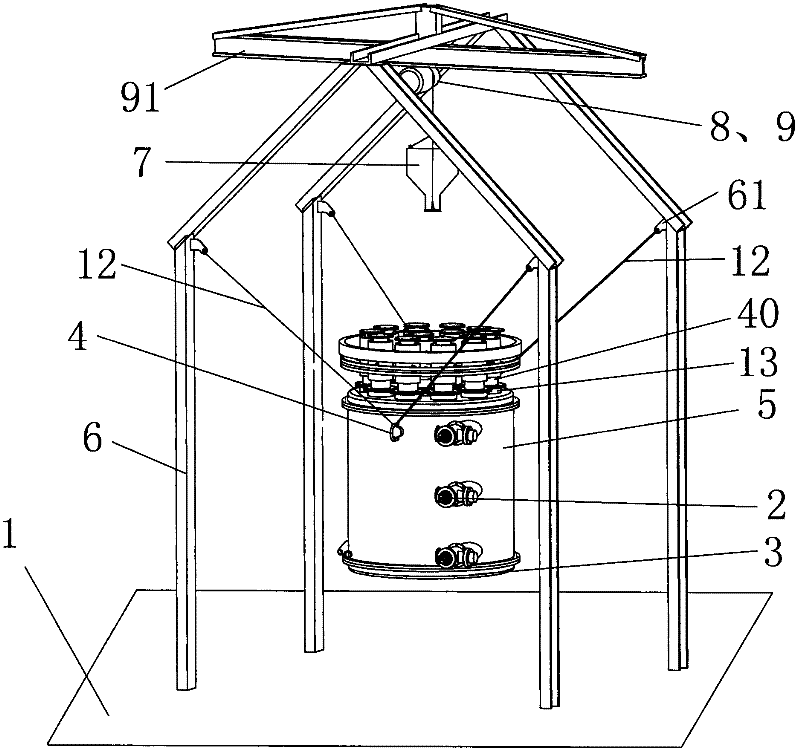

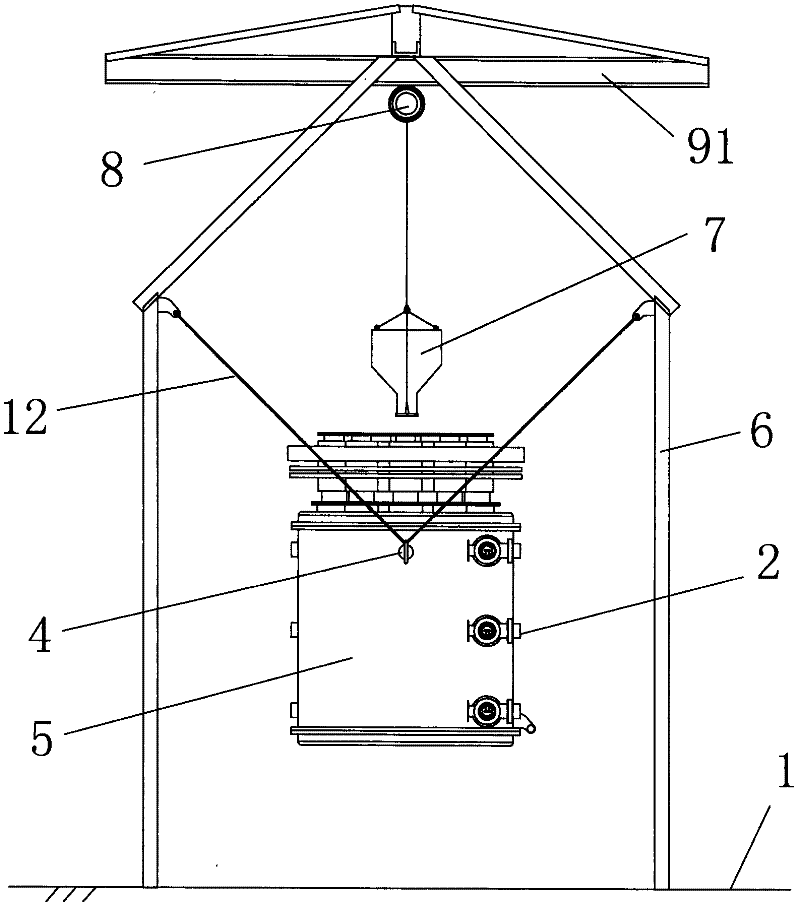

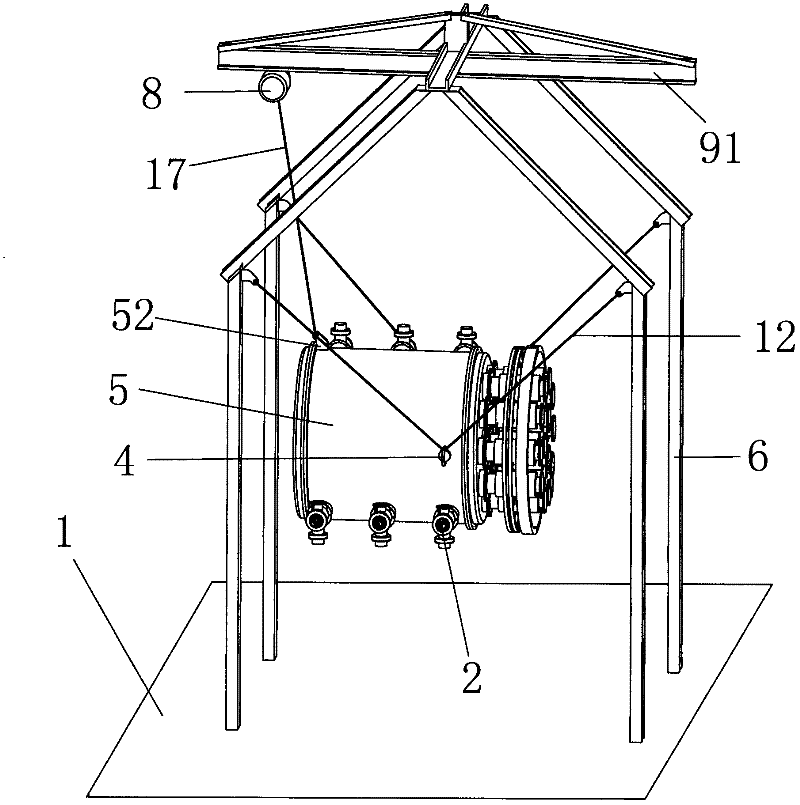

[0041] As shown in the figure, this reduction furnace is a suspension type, and the metal furnace body of the reduction furnace can be turned over. When the mouth of the reduction tank is facing up, the electric hoist can be used to mechanically load the material. When the mouth of the reduction tank is facing down, the end cover is removed, that is It can be unloaded by self-weight, and it can be fired horizontally or vertically. It is mainly composed of a reduction furnace metal furnace body, a reduction tank, a burner, a suspension device, a walking mechanism, a charging mechanism and a regenerator heat exchange device.

[0042] Such as Figure 1-4 As shown, the suspension device is mainly used for suspending the metal furnace body 5 of the reduction furnace, on which a walking mechanism 9 and a charging mechanism 7 for feeding materials are also arranged....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com