Biomass fuel combustion device

A biomass fuel and combustion device technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of large floor area, billowing black smoke, low boiler thermal efficiency, etc., and achieve less pollutant emissions, Promotes complete combustion and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

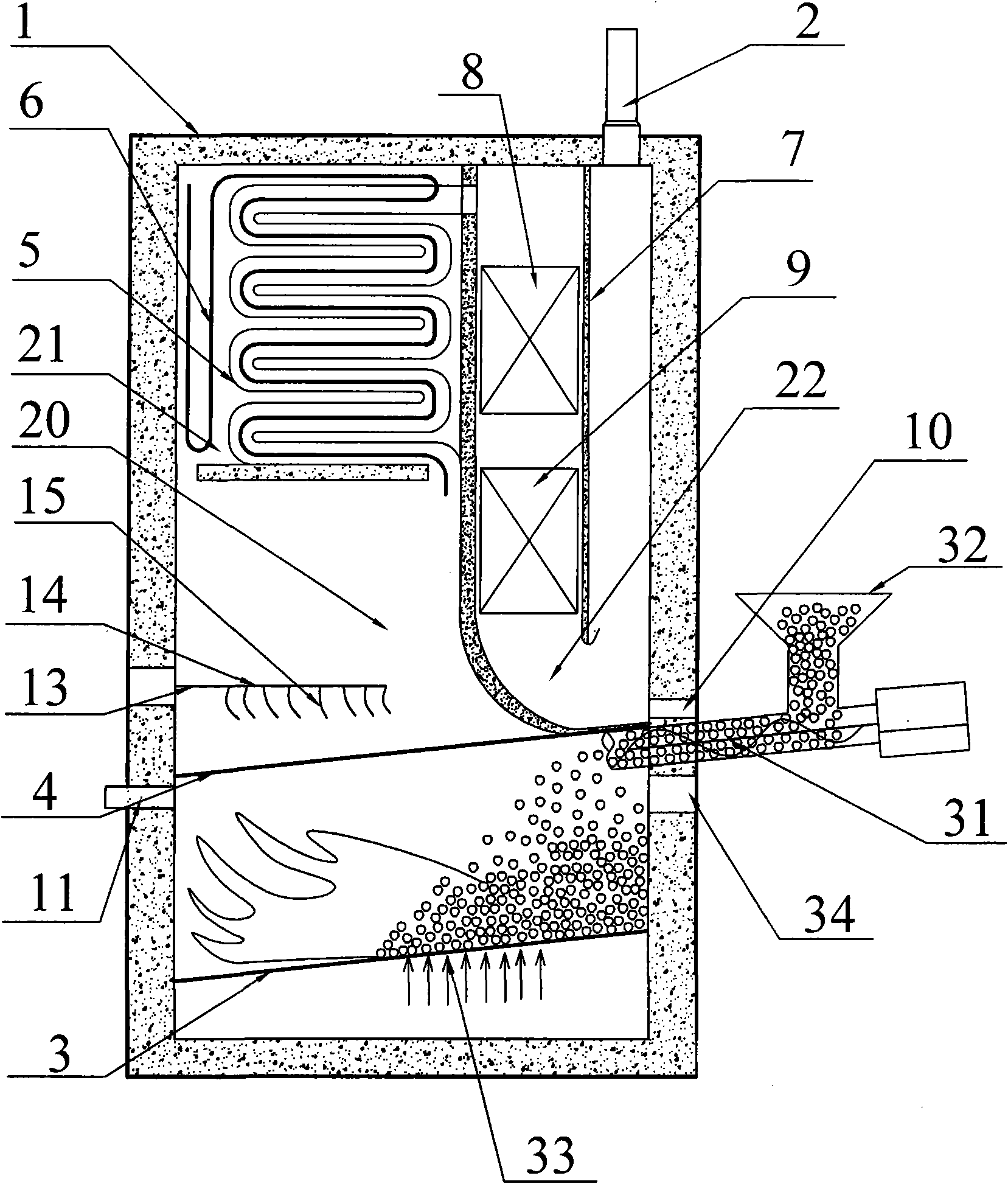

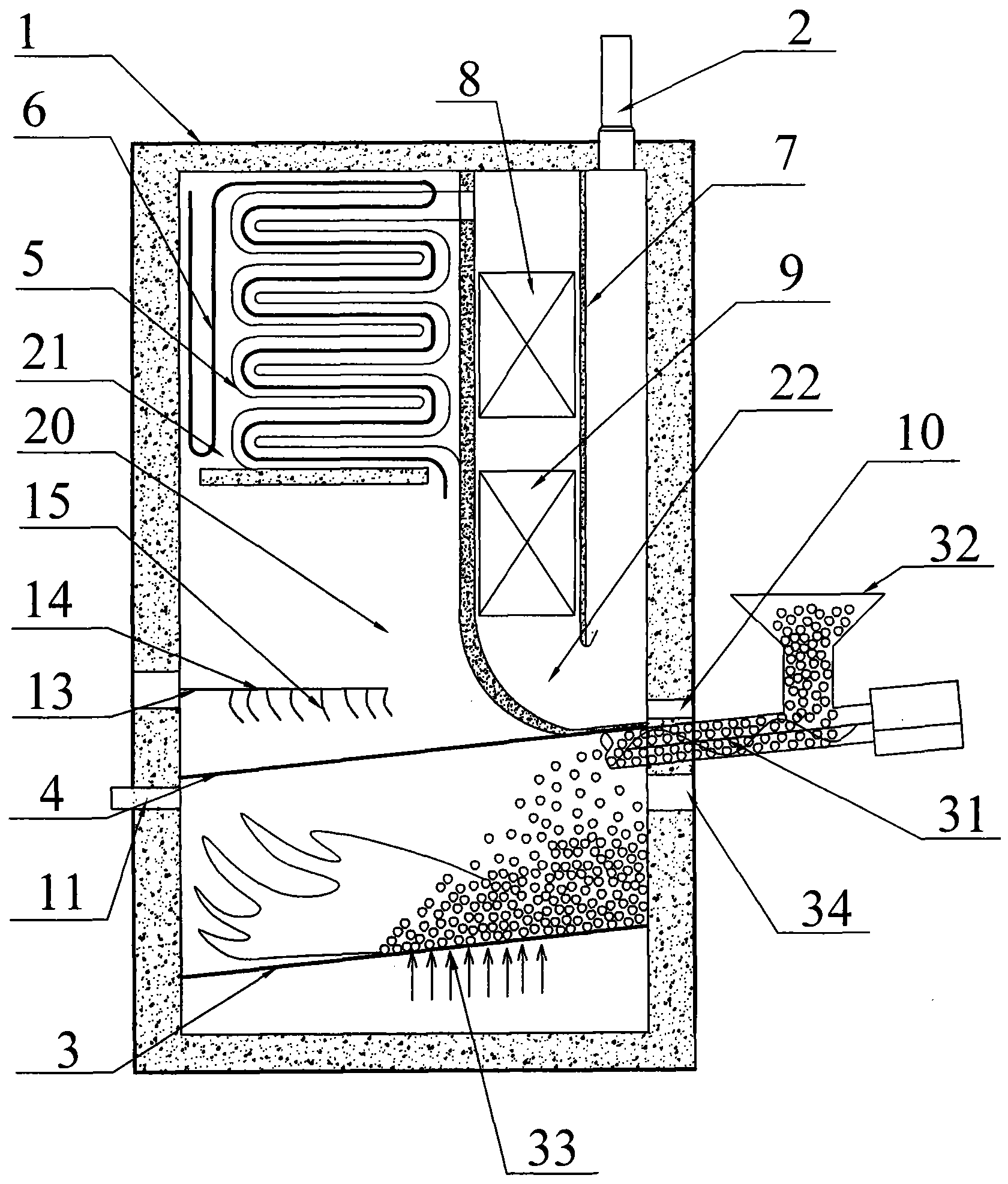

[0016] like figure 1 As shown, the present invention includes a vertical combustion furnace 1, the top of the vertical combustion furnace 1 is provided with a smoke exhaust passage 2, and the inside of the vertical combustion furnace 1 includes a combustion chamber 20, a heat exchange chamber 21, a flue gas Expansion chamber 22, the combustion chamber 20 is provided with an upper grate 3, a lower grate 4 and a tertiary air intake device, the upper grate 3 and the lower grate 4 adopt a membrane structure, which not only increases The heat transfer area also improves the conduction coefficient, and the heat transfer speed is fast. Therefore, the boiler furnace temperature field is evenly distributed and the thermal efficiency is high. On the side wall of the vertical combustion furnace 1 and between the upper grate 3 and the lower grate 4, a feeding device is provided. The feeding device includes a screw The feeder 31 and the hopper 32 arranged on the screw feeder 31, the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com