Vacuum type microwave rotary roller drying device

A technology of rotary drum and drying equipment, which is applied in the direction of drying solid materials, lighting and heating equipment, dehydration/drying/thickened sludge treatment, etc. Uniformity and other issues, to achieve the effect of improving equipment use efficiency, equipment drying environment safety, and short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

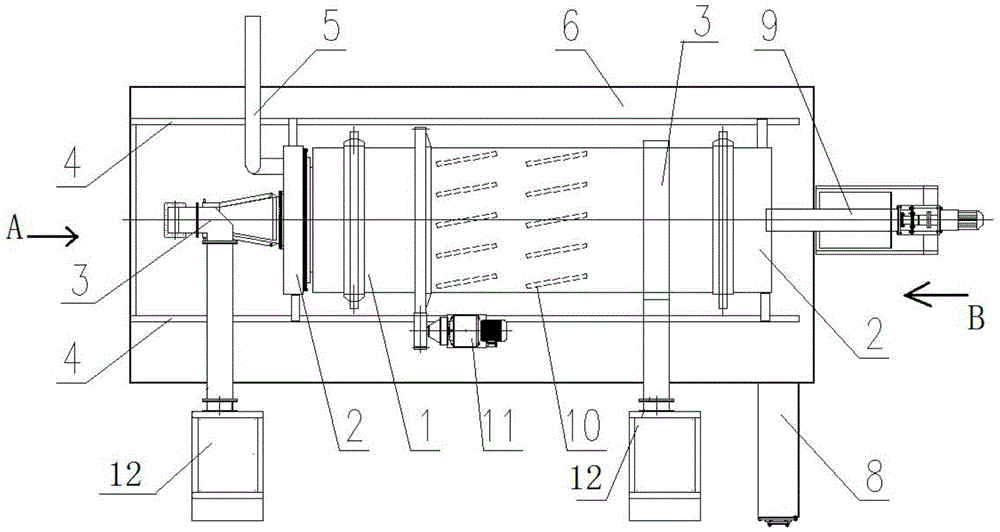

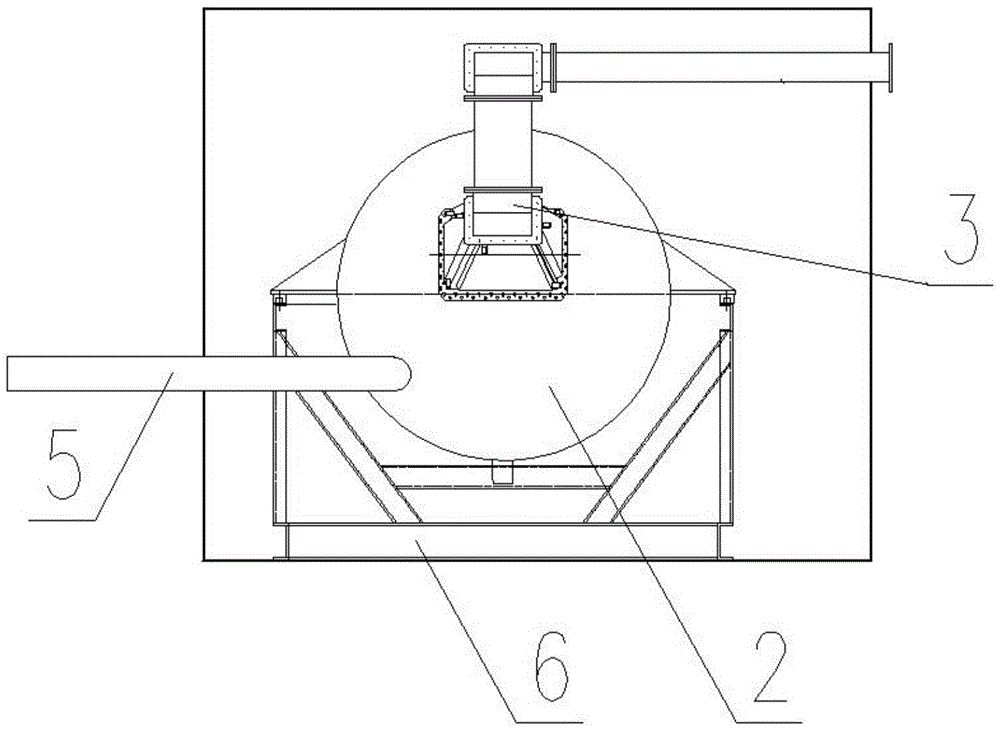

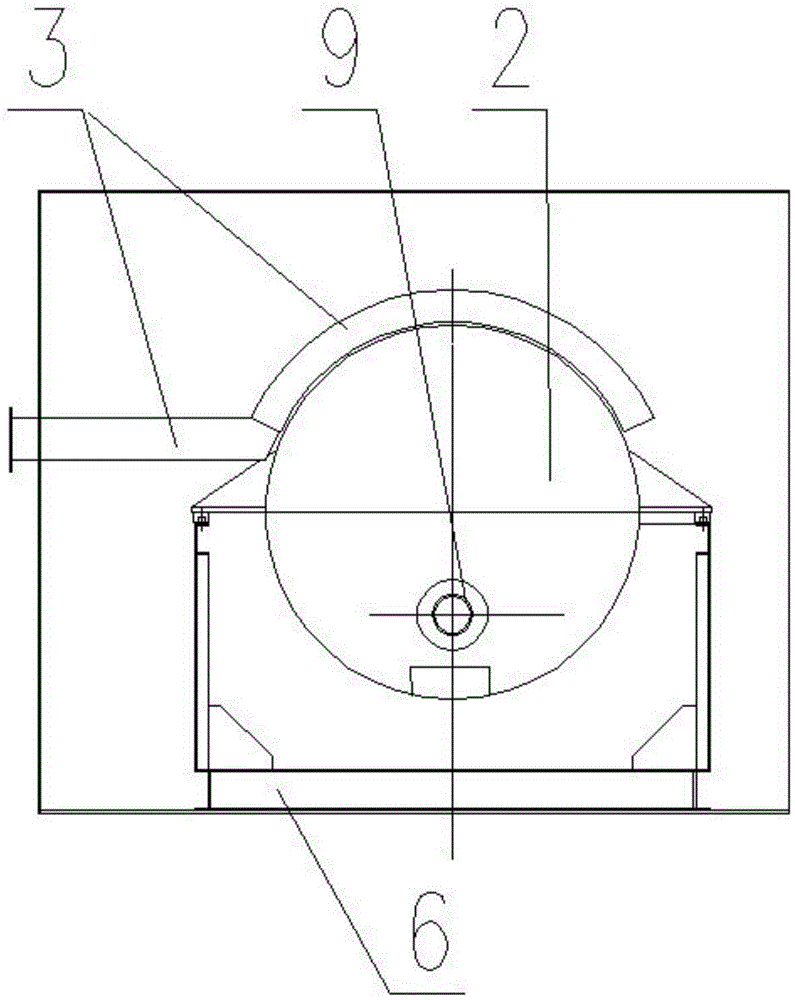

[0025] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

[0026] Such as Figure 1 to Figure 3 Shown, a kind of vacuum type microwave rotary drum drying equipment, it comprises airtight box body (6), is installed in the rotary drum (1) in airtight box body (6), is installed in the sealing cover ( 2), the material feed port (9) installed on one end of the rotary drum (1); the rotary drum (1) is equipped with a microwave feeding port (3) in the axial direction and in the circumferential direction, and the microwave feeding port (3) ) is connected with microwave generator (12), described rotary drum (1) is driven to rotate by motor (11), offers vacuum exhaust port (5) and material discharge port ( 8), the vacuum exhaust port (5) is connected with a cooler, and the cooler is connected with the storage tank; the material inlet (9) and the material outlet (8) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com