Patents

Literature

43results about How to "Realize heating and drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cultivation soil refining equipment used for garden potted cultivation

InactiveCN111036324AReasonable structureSimple designGrowth substratesCulture mediaAgricultural scienceElectric machine

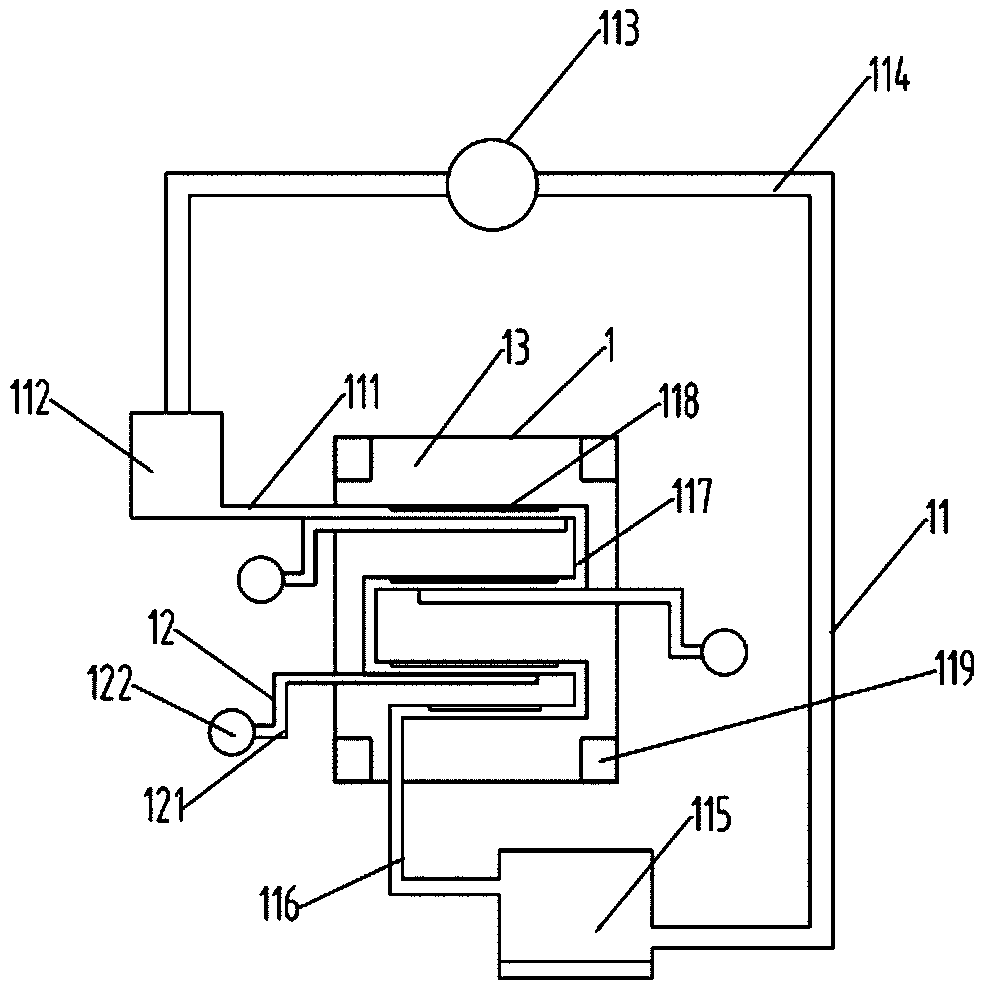

The invention discloses cultivation soil thinning equipment used for garden potted cultivation. The equipment comprises a seal cover, a motor, a control switch, a scraping plate, a heating pipe, a push plate and a refining box. The seal cover is opened, cultivation soil can further enter the refining box, the control switch is used for starting the motor, the motor rotates to drive a smashing blade on a smashing rotating shaft to rotate to carry out smashing and refining on the cultivation soil in the refining box, the heating pipe is used for heating, heating drying of the cultivation soil inthe refining box can be further achieved, the phenomenon that due to the too large humidity, the cultivation soil is adhered, and smashing and refining effects are affected can be avoided, wet air generated by heating in the refining box is further discharged through a feeding opening of the refining box, after smashing and refining are finished, the scraping plate is driven by the smashing rotating shaft to scrap down the adhered cultivation soil on the inner side of a protection cover, the push plate is driven by the smashing rotating shaft to push the cultivation soil on the bottom of theinner side of the refining box, and the cultivation soil in the refining box is completely discharged out through a discharging pipe.

Owner:NINGBO CITY COLLEGE OF VOCATIONAL TECH

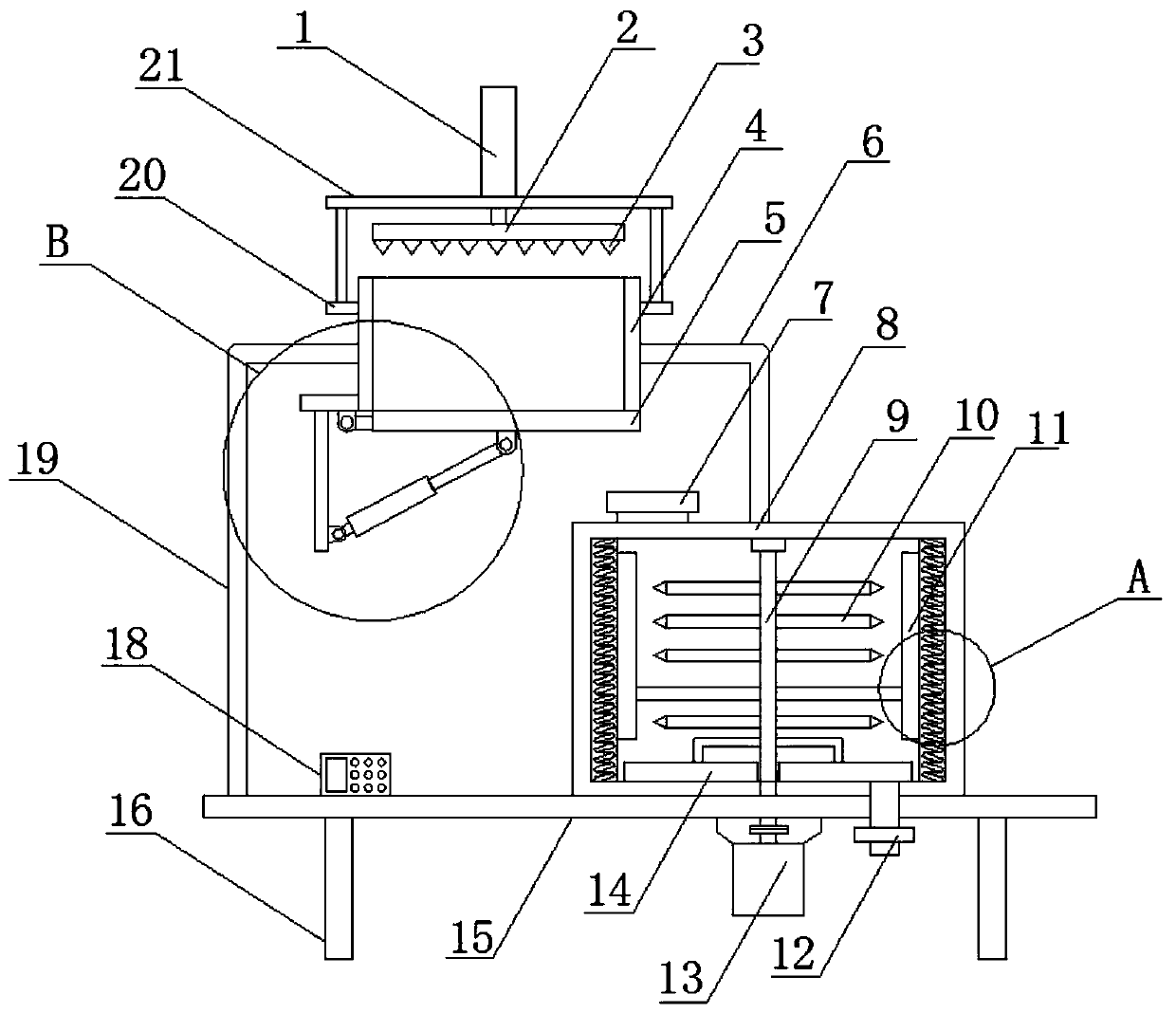

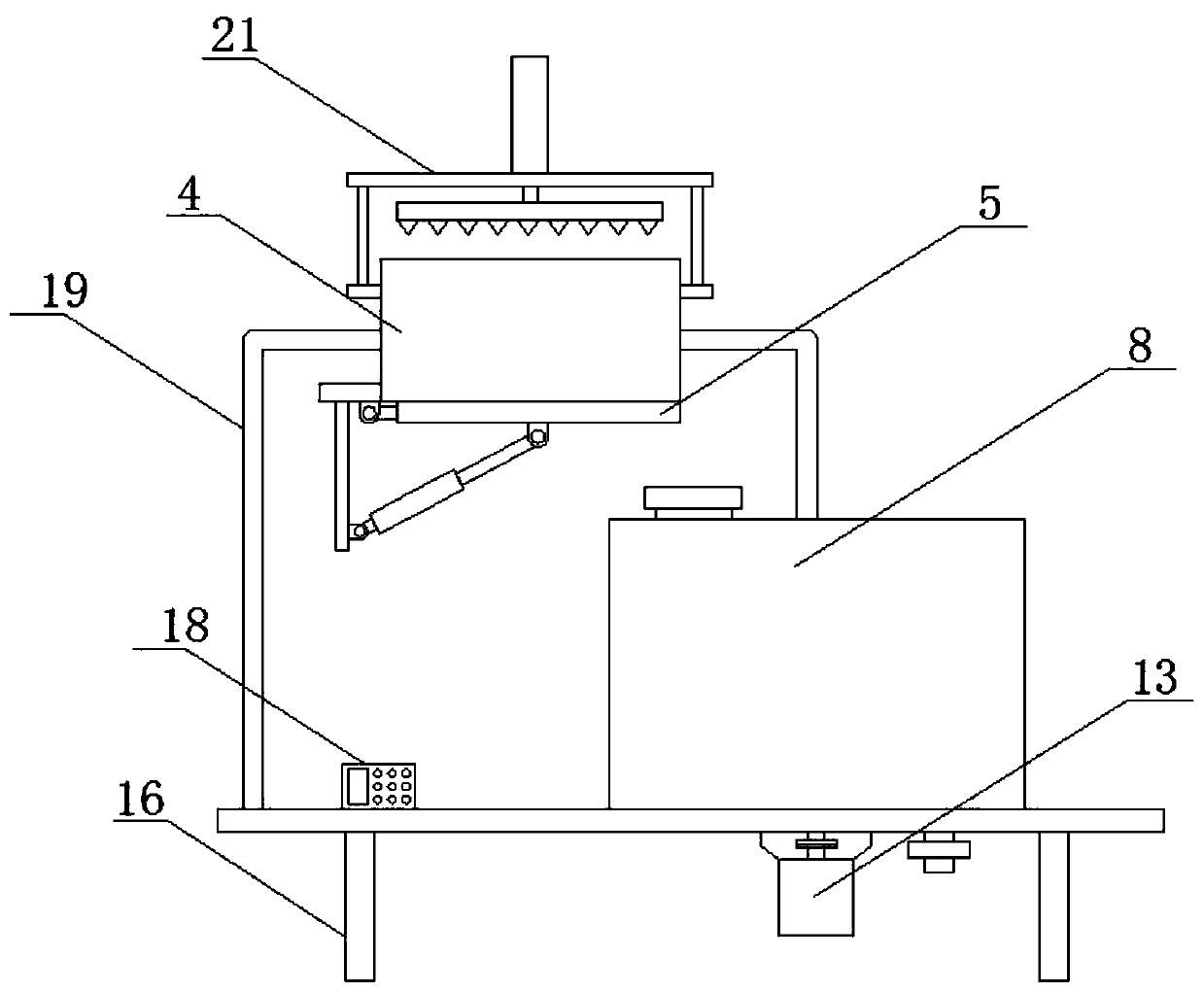

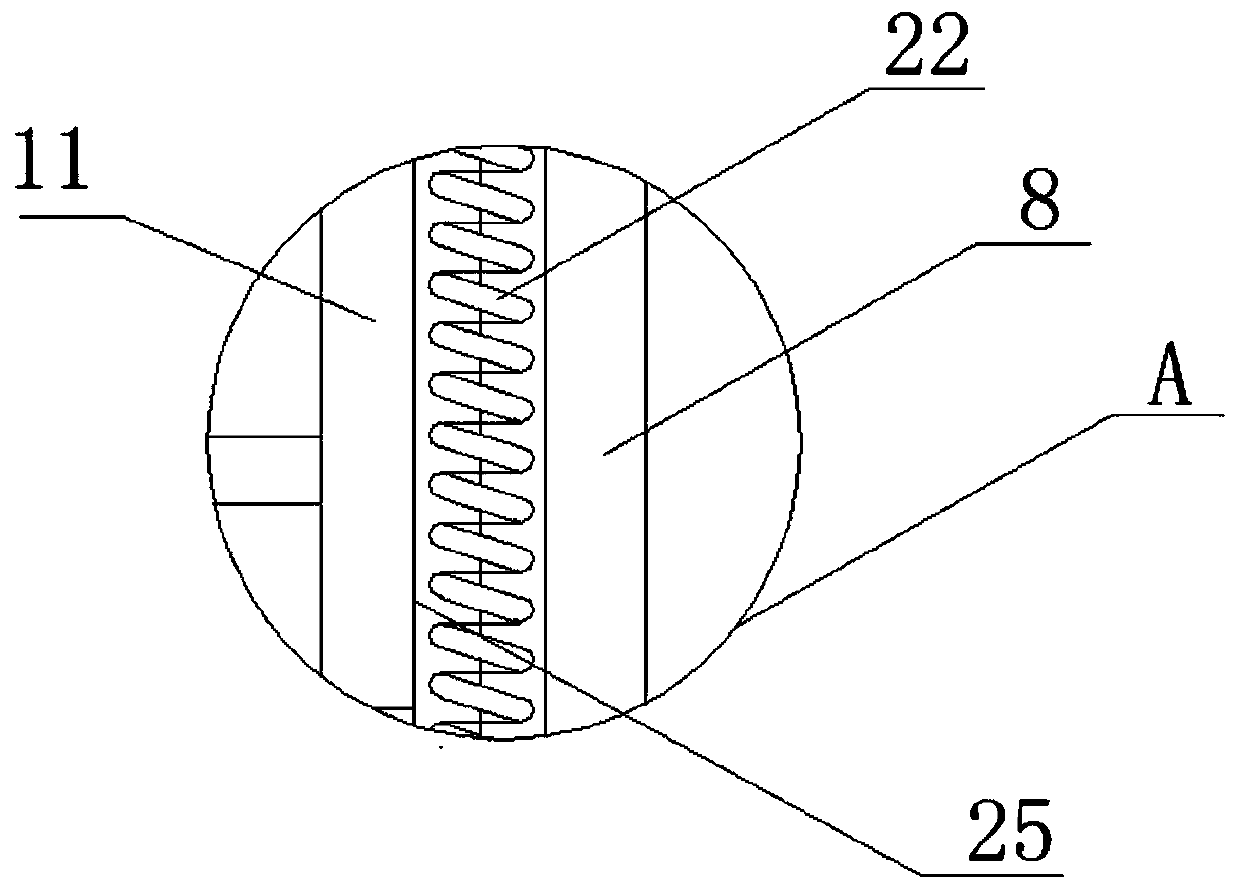

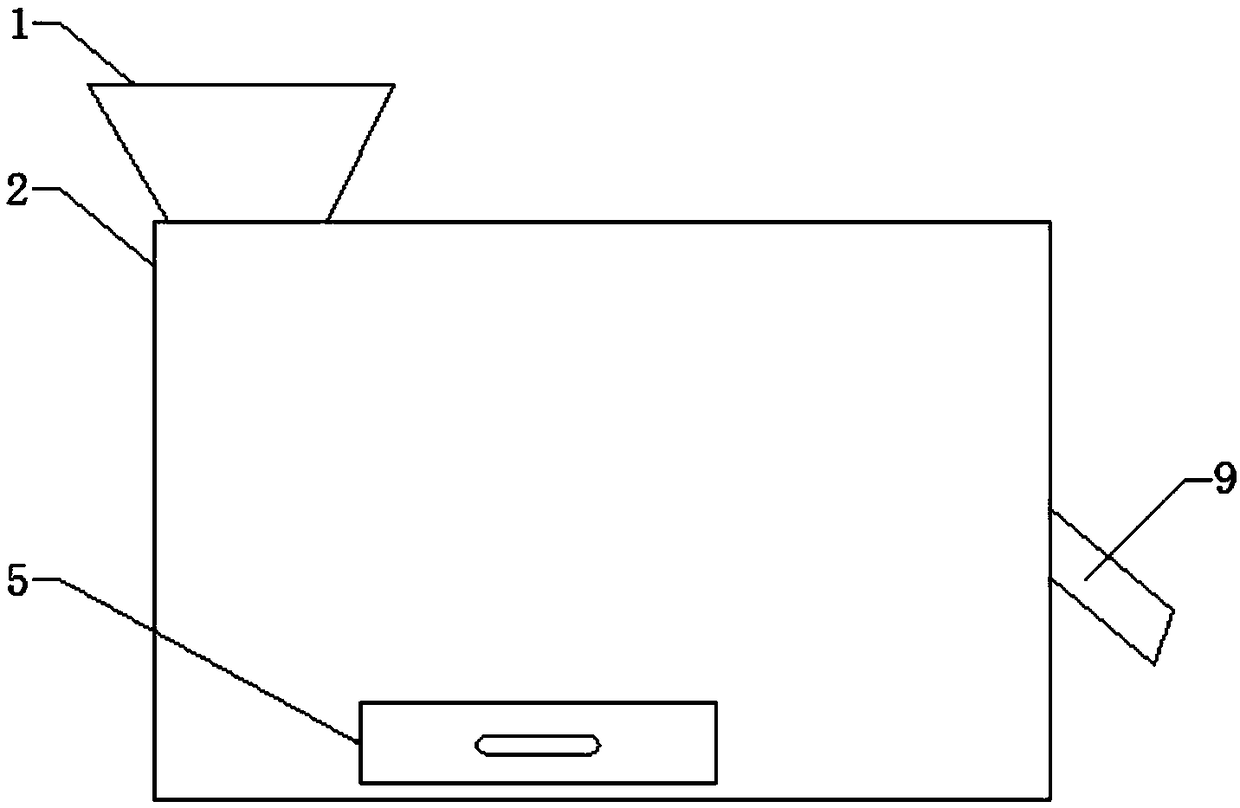

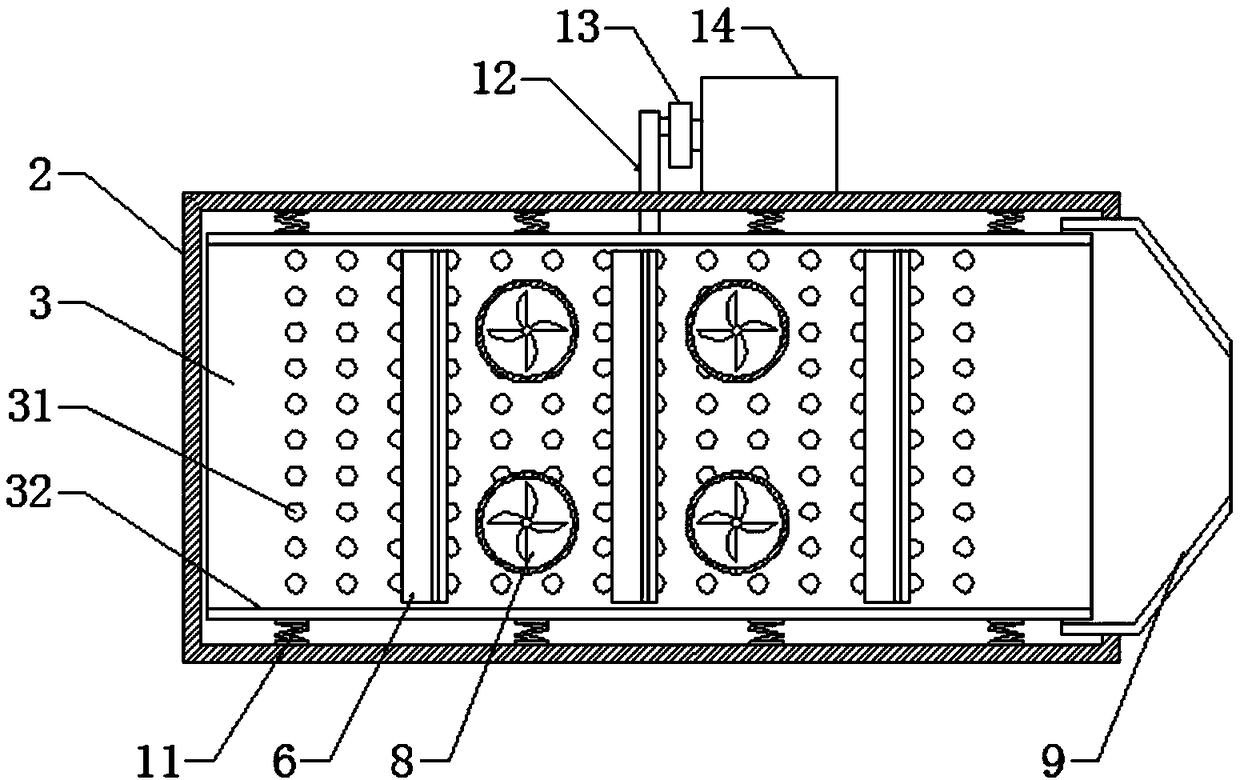

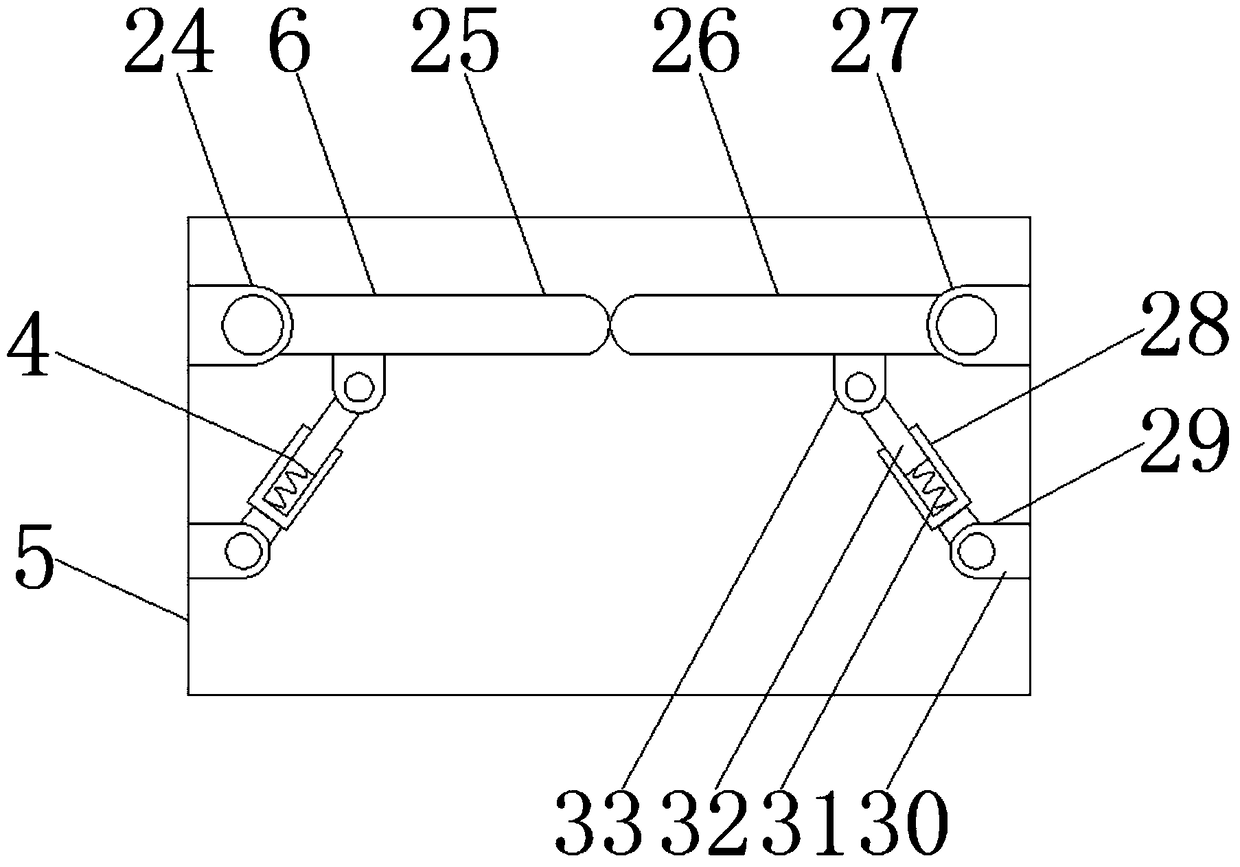

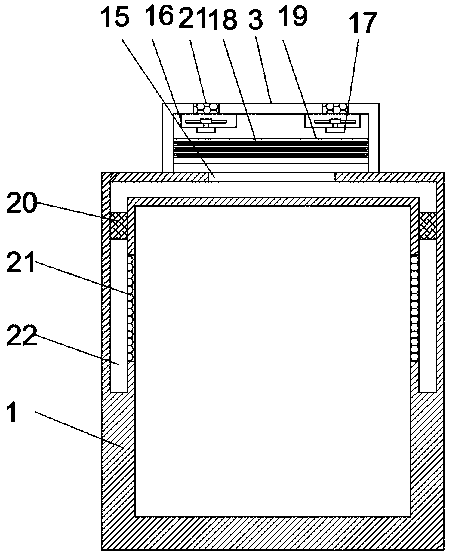

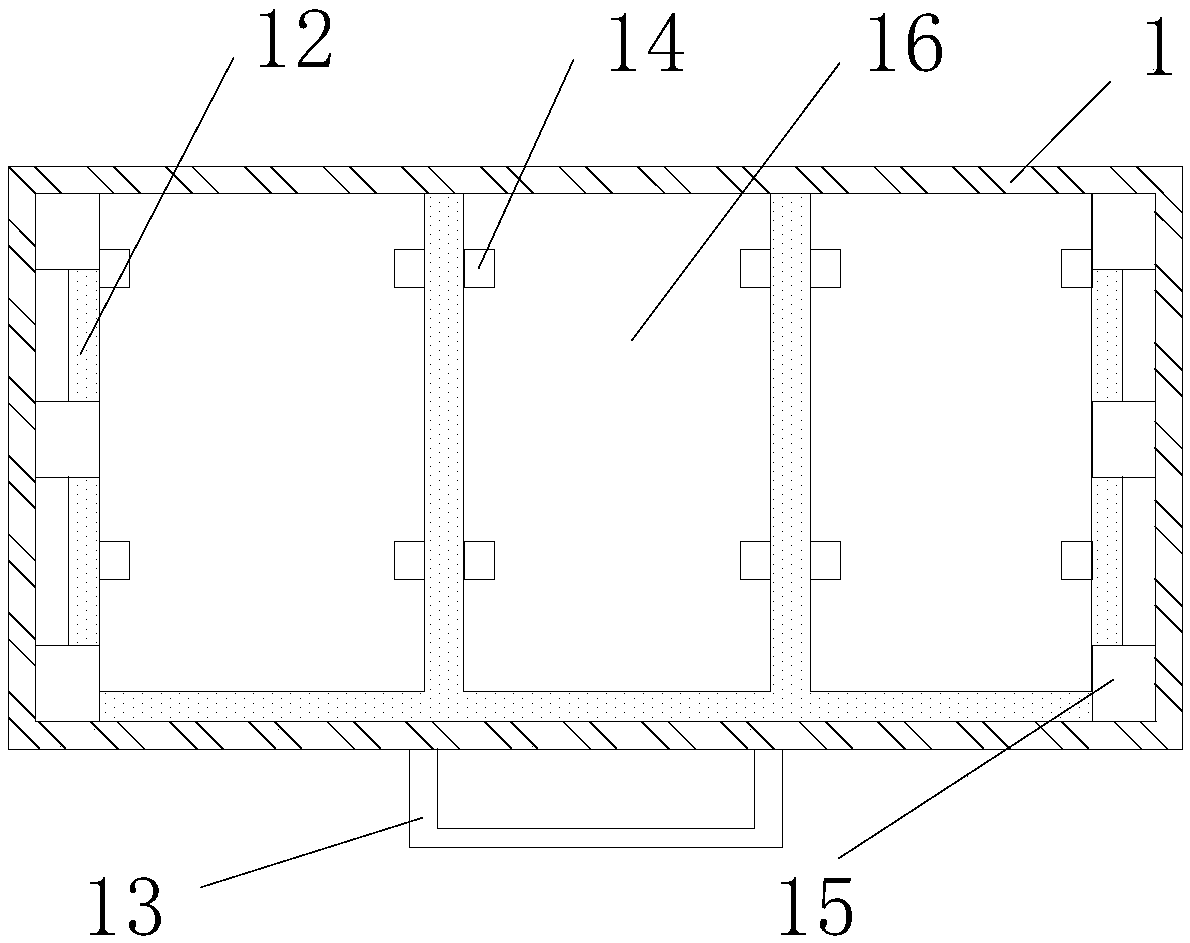

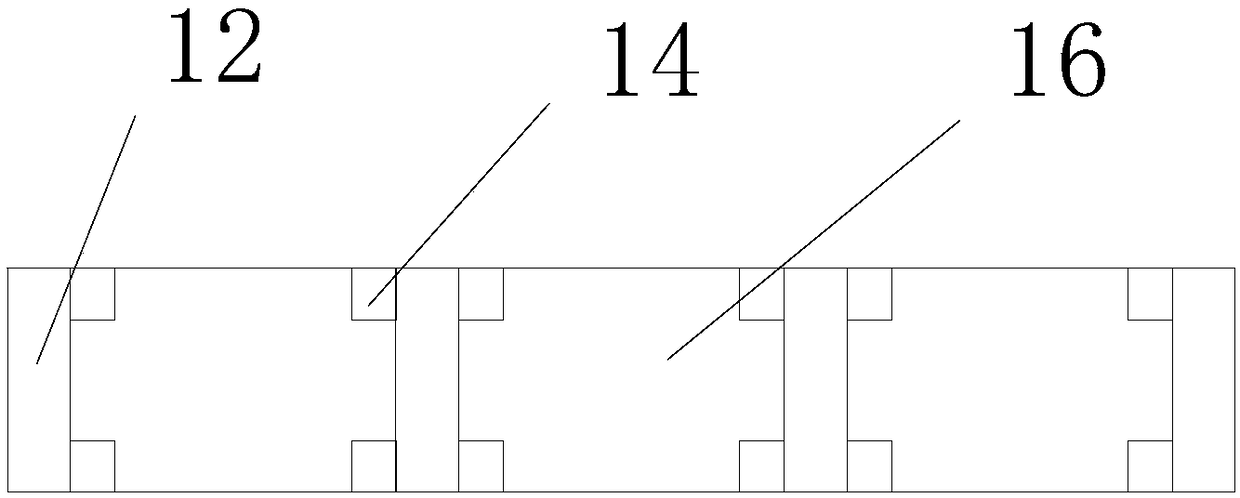

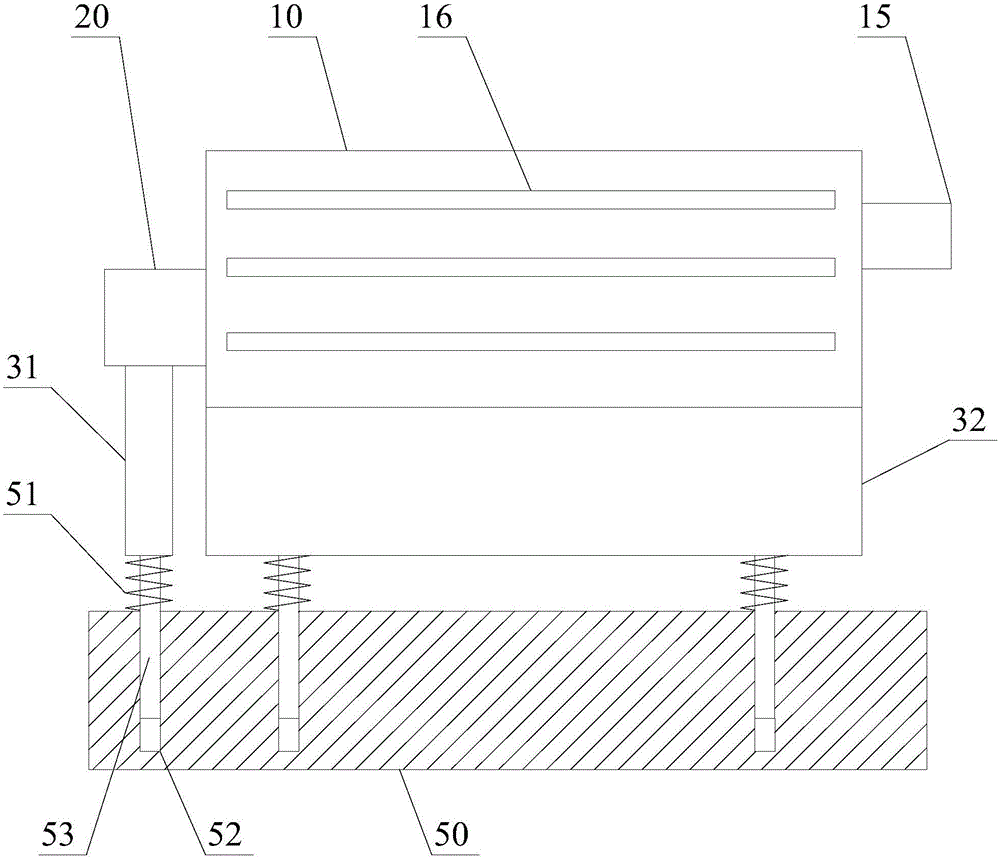

Pet feed drying device

PendingCN109059524AAchieve dryingAvoid extrusion deformationSievingGranular material dryingMotor driveEngineering

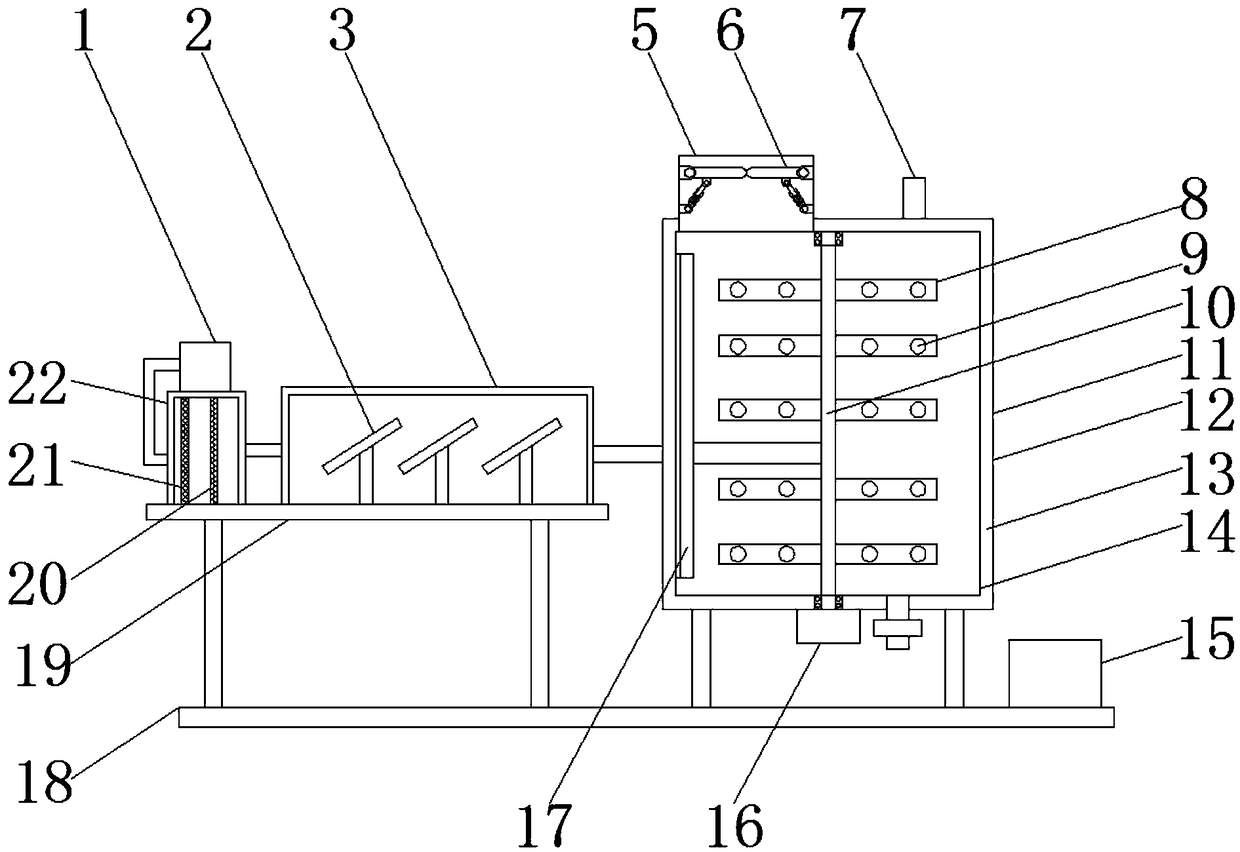

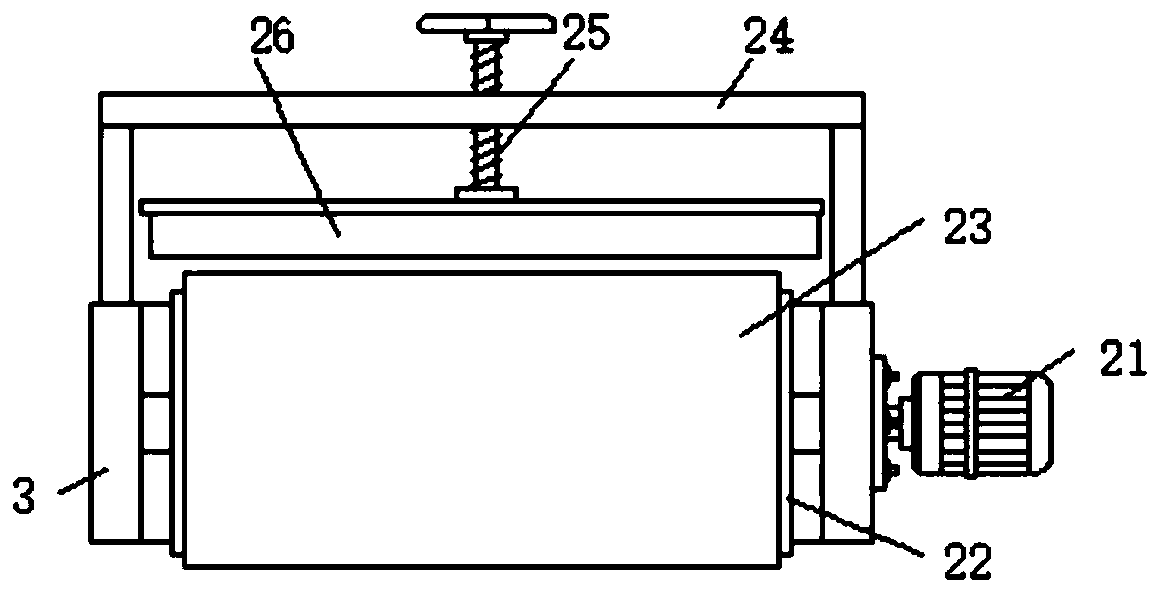

The invention discloses a pet feed drying device. The pet feed drying device comprises a hopper, a box body, a heating plate, a fan and electric heating sheets, wherein the position, close to the leftend, of the upper surface of the box body is equipped with the hopper; the inner side of the box body is transversely equipped with the heating plate; the heating plate tilts towards the right lowercorner; the electric heating sheets are uniformly distributed on the lower surface of the heating plate; and three partitions which are uniformly arranged in a tilting direction of the heating plate are arranged above the heating plate. The drying device swings the heating plate through a motor driven swing mechanism, and a spring arranged between the heating plate and the box body realizes rolling spherical granular feed to a lower position when the heating plate vibrates; the inclined heating plate enables the spherical feed to roll to the lower position while drying of the feed is realized;and the L-shaped partitions are arranged for spreading the rolling spherical granular feed, so that extrusion deformation caused by accumulating is avoided.

Owner:德清德盛宠物用品科技股份有限公司

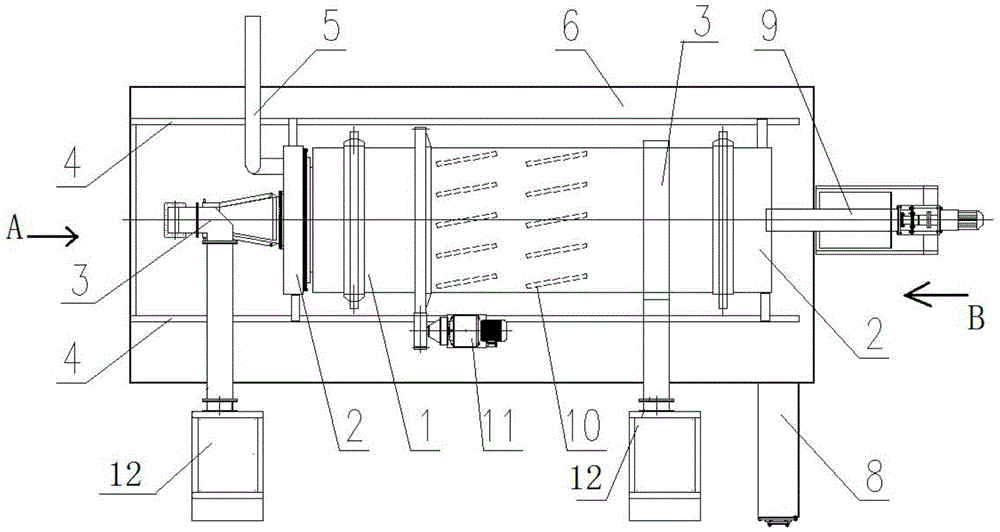

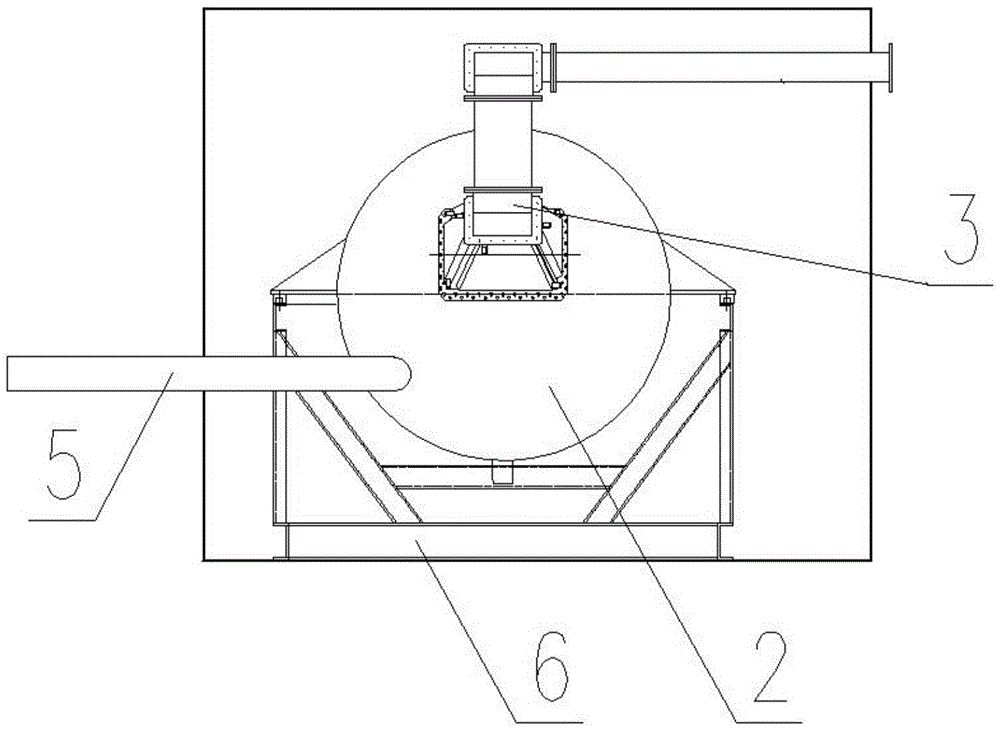

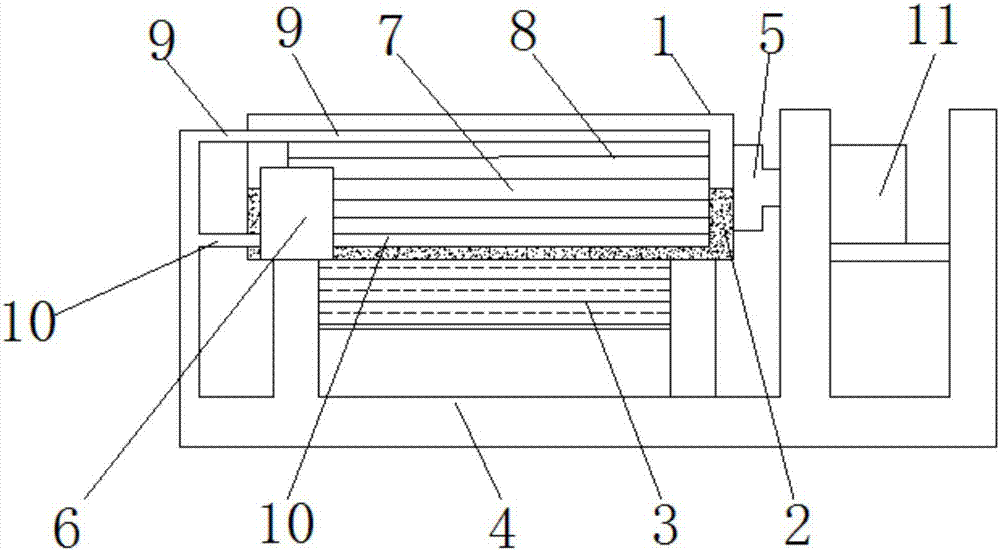

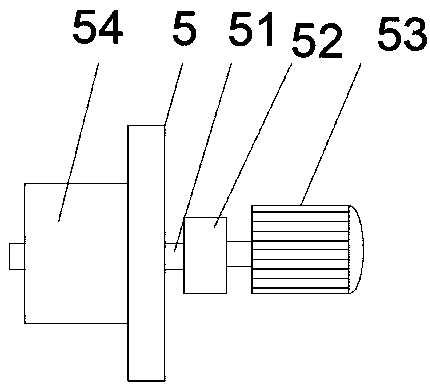

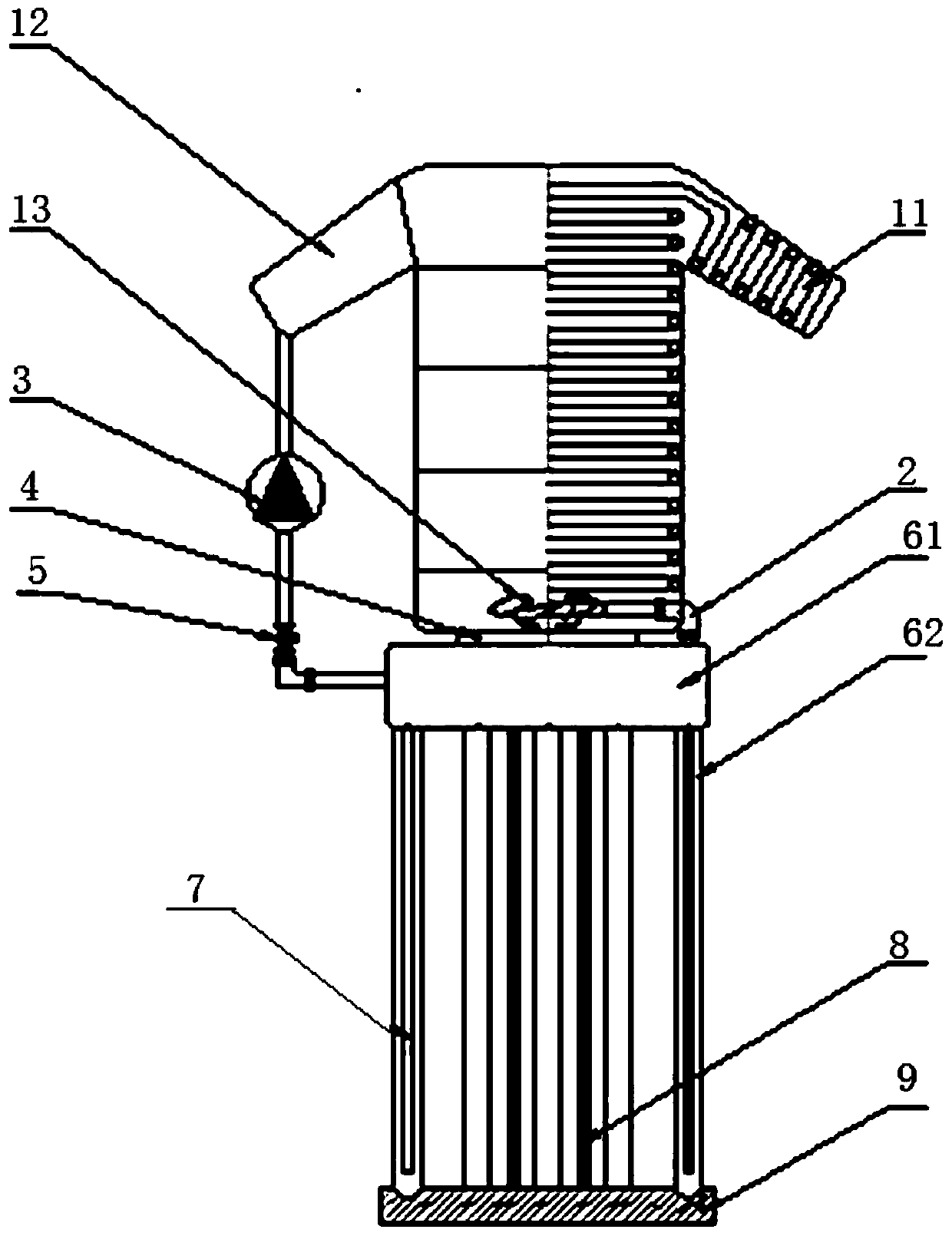

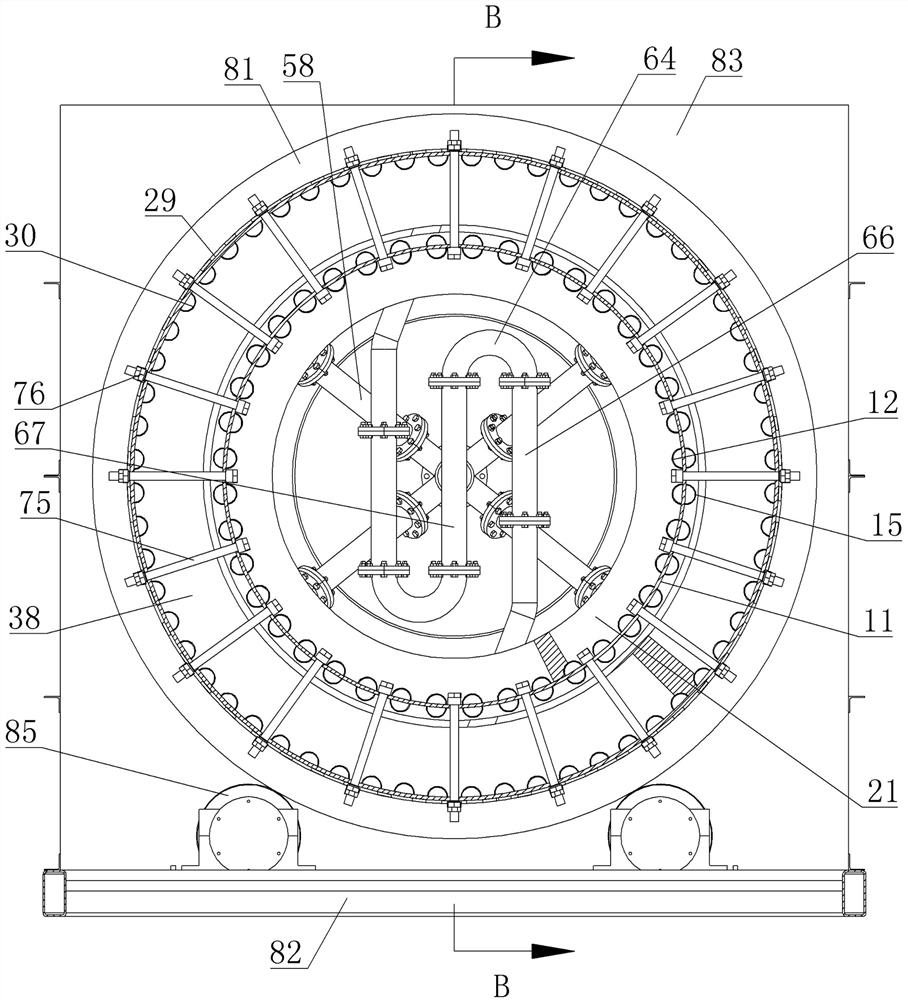

Vacuum type microwave rotary roller drying device

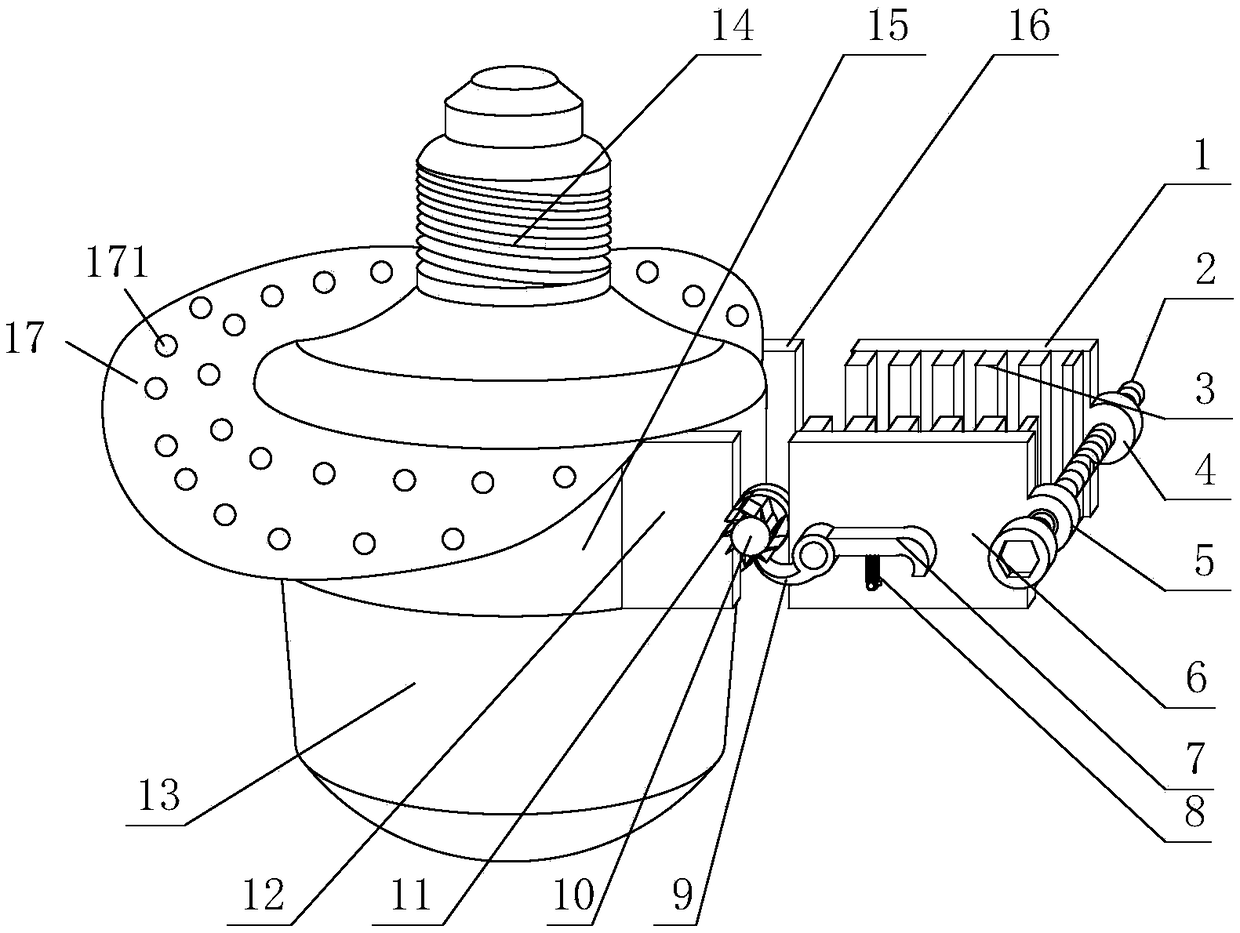

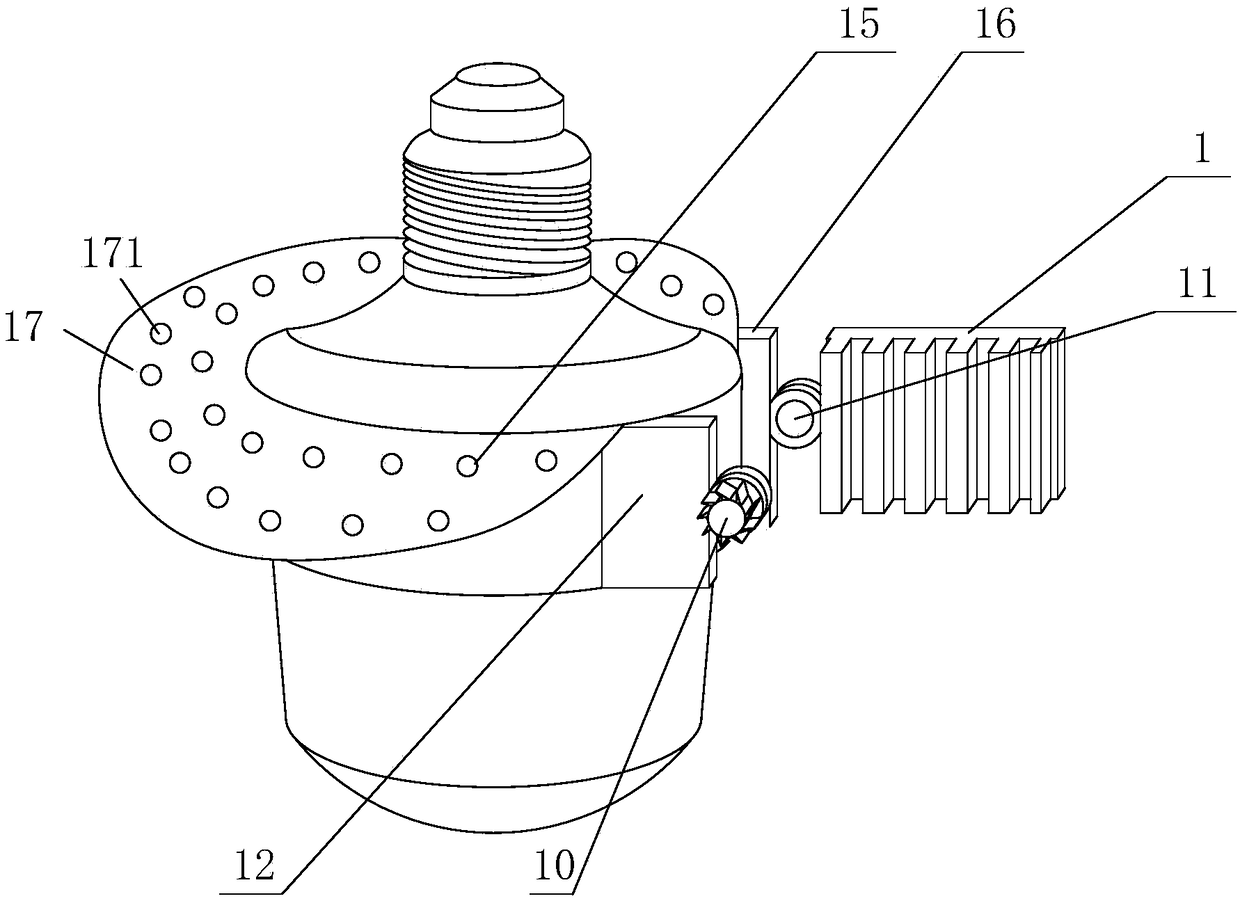

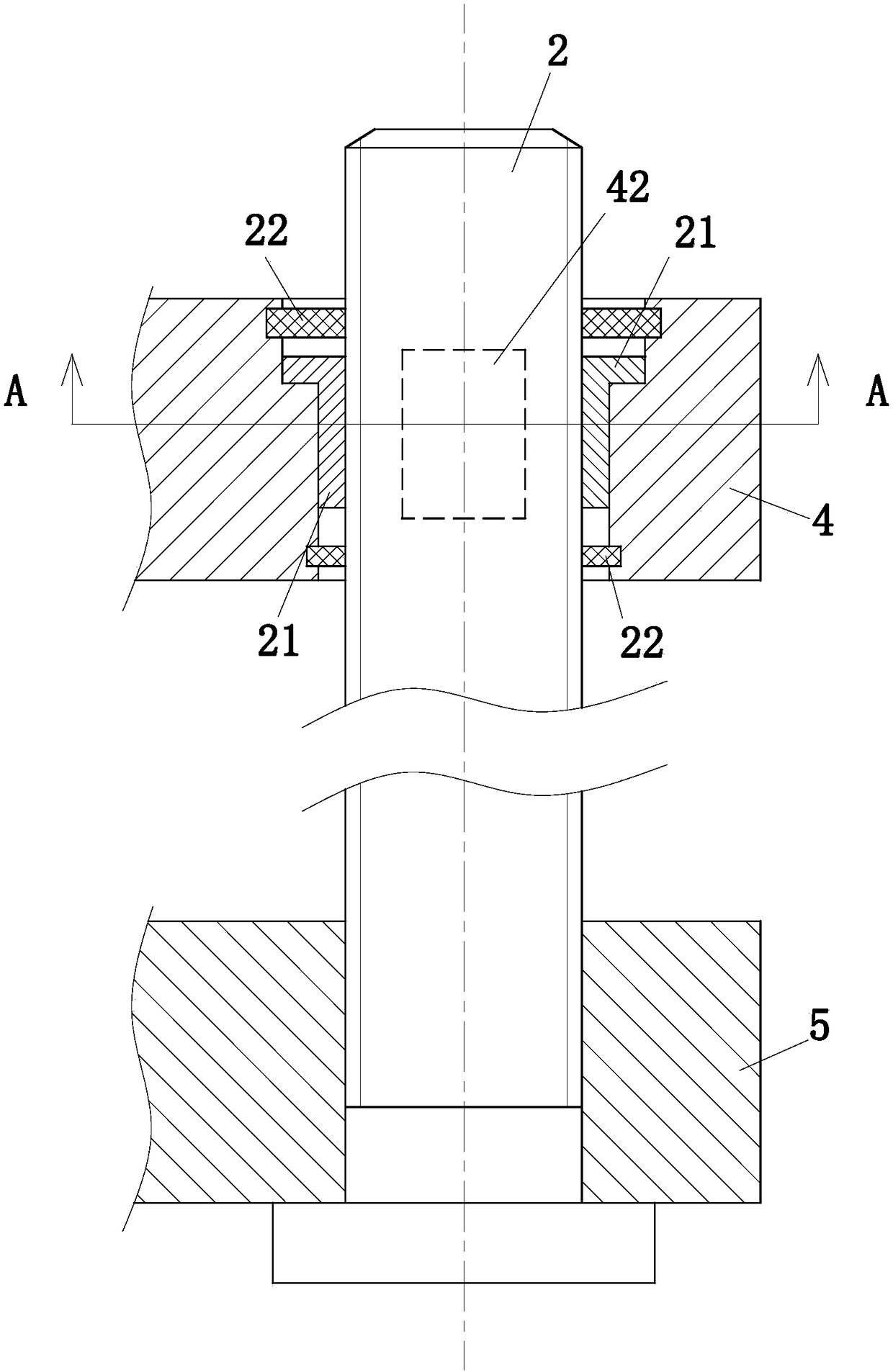

InactiveCN105466197ARealize heating and dryingFast heating and dryingSludge treatment by de-watering/drying/thickeningWater/sewage treatment by irradiationMicrowaveElectric machine

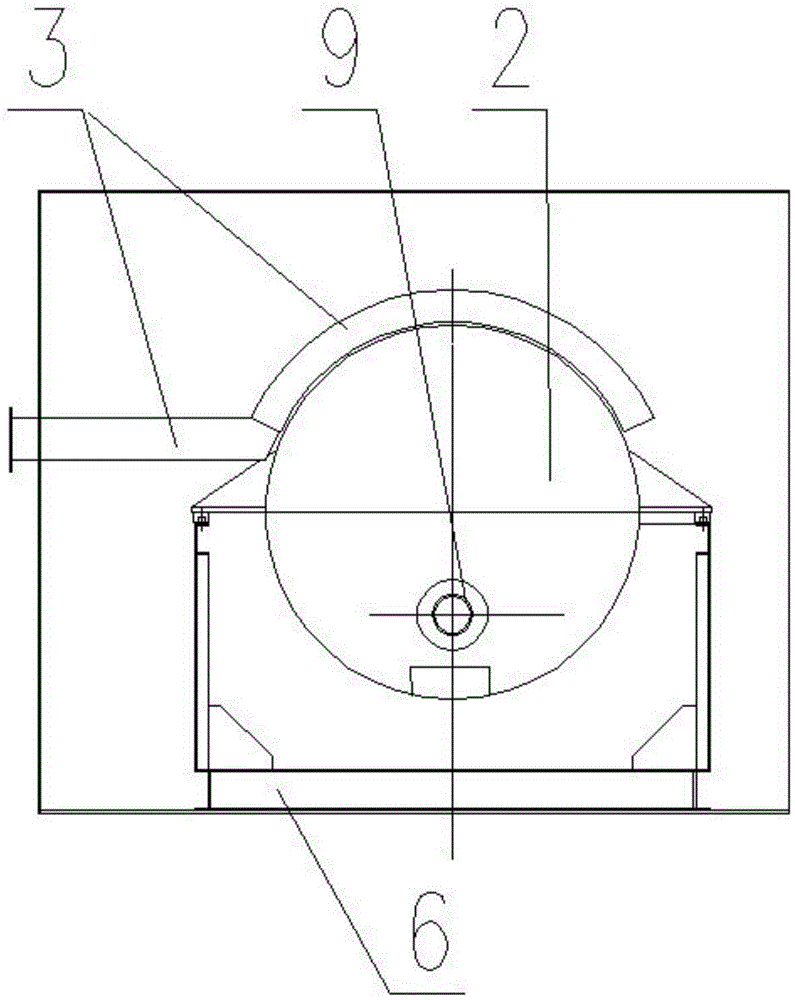

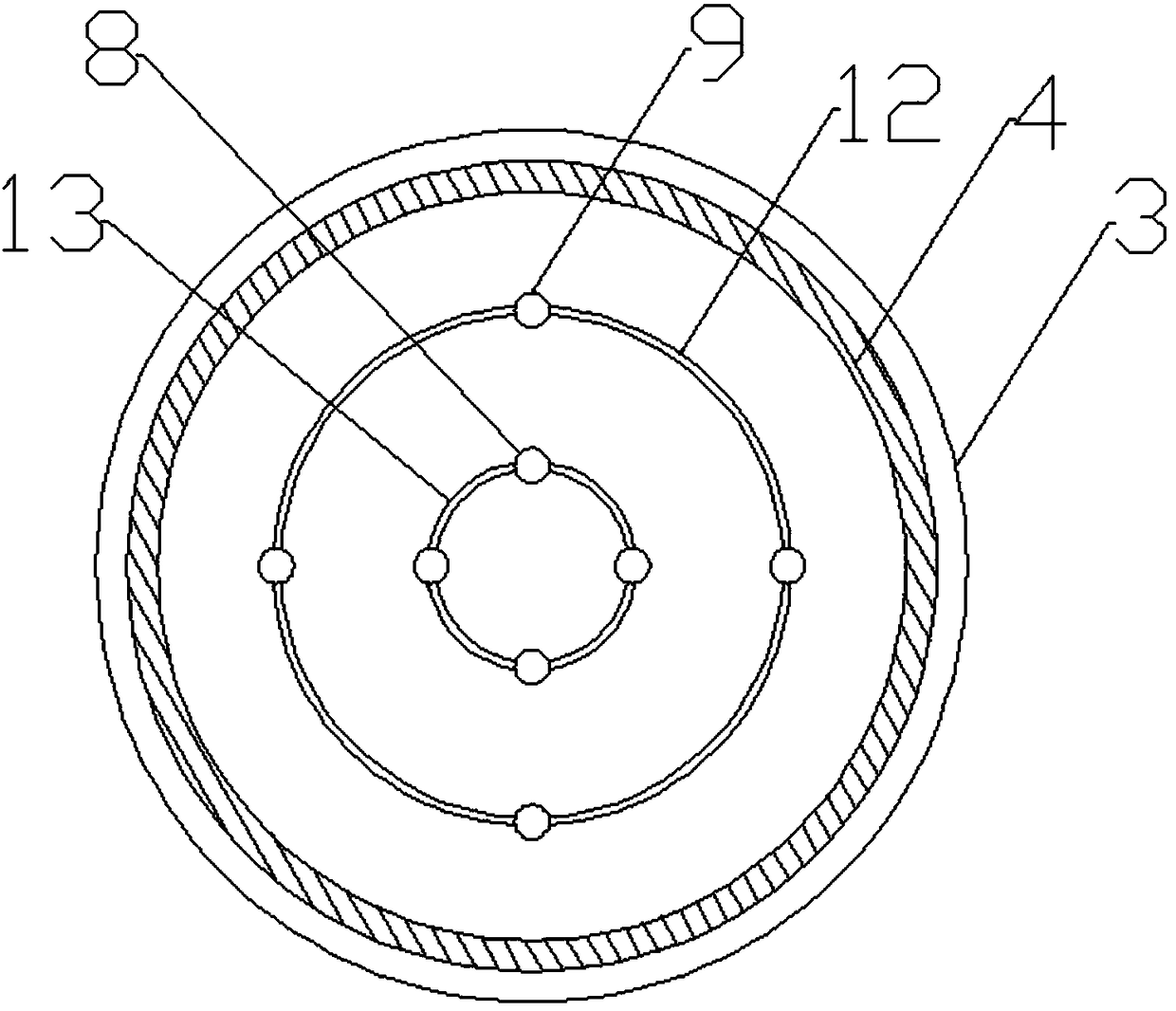

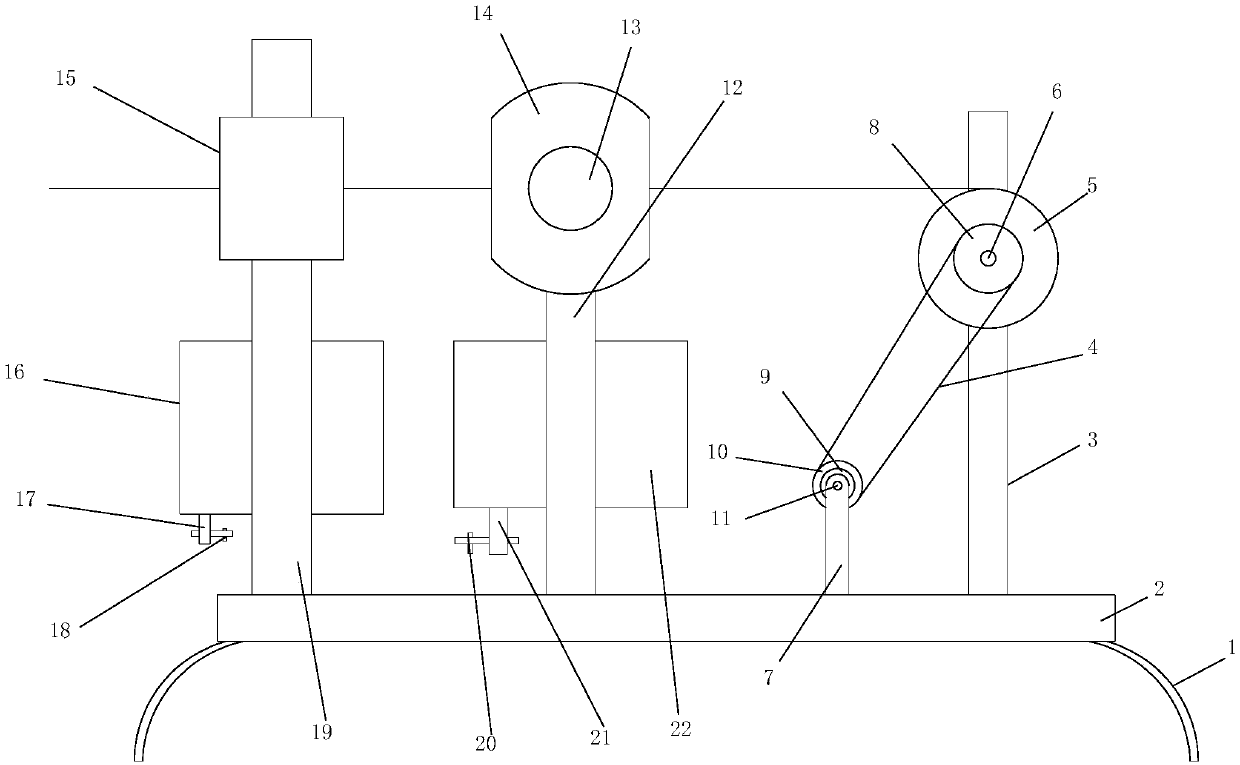

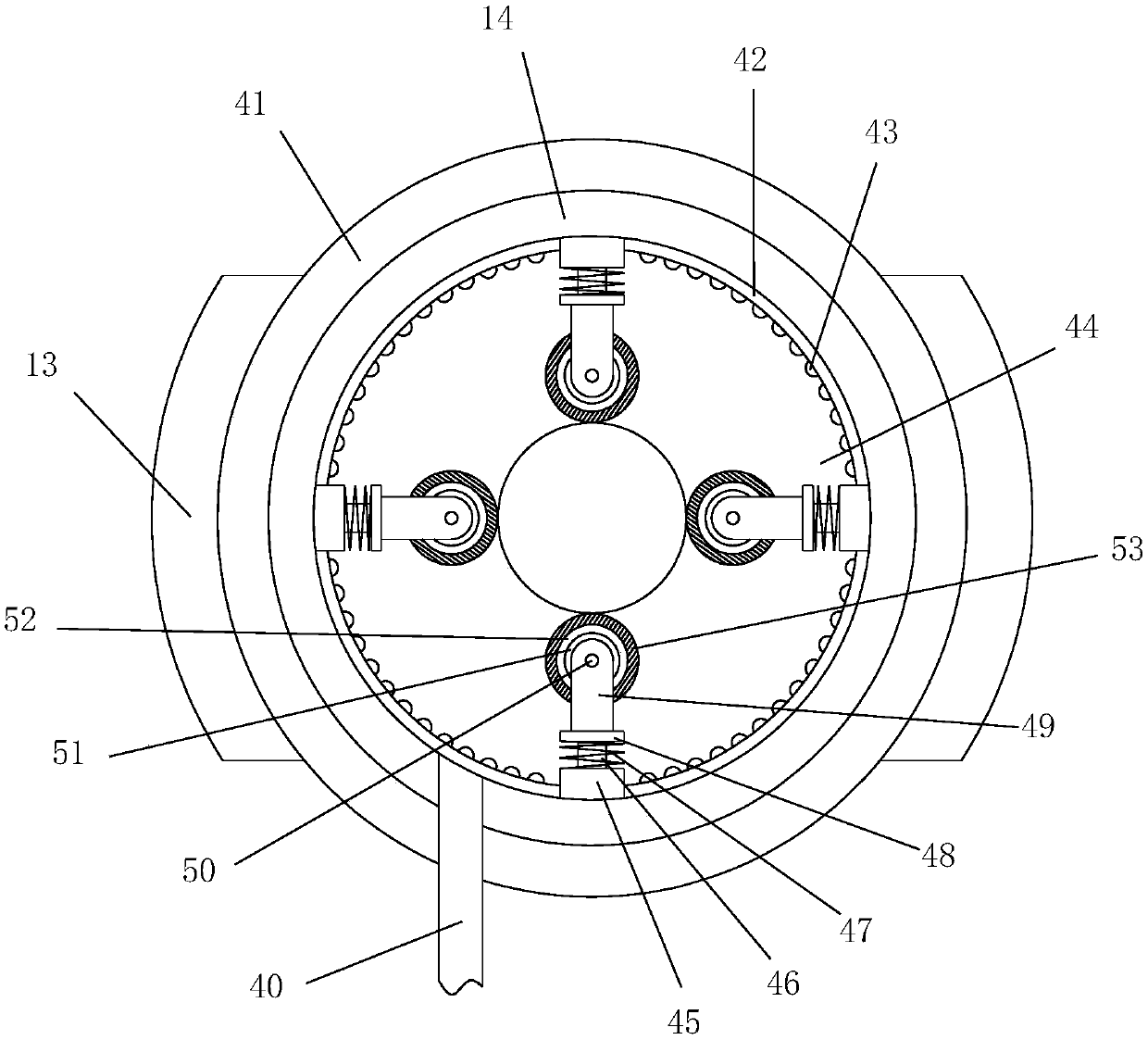

The invention discloses a vacuum type microwave rotary roller drying device. The drying device comprises a sealed box body (6), a rotary roller (1) mounted in the sealed box body (6), sealing covers (2) mounted at the two ends of the rotary roller (1) and a material inlet opening (9) formed in one end of the rotary roller (1); microwave feed openings (3) are formed in the axial direction and the radial direction of the rotary roller (1), and are connected with a microwave generator (12), and the rotary roller (1) is driven by a motor (11) to rotate; a vacuum exhaust opening (5) and a material discharging opening (8) are formed in the rotary roller (1), and the vacuum exhaust opening (5) is connected with a condenser; and the condenser is connected with a storage tank. The drying device is reasonable in design and convenient to operate, under the vacuum negative pressure, axial and radial microwave heating is adopted, flammable substance is prevented from combusting and exploding, the safety performance is good, the heat utilization efficiency is high, the heating work efficiency is high, and the application range is quite wide.

Owner:NANJING SANLE MICROWAVE TECH DEV +1

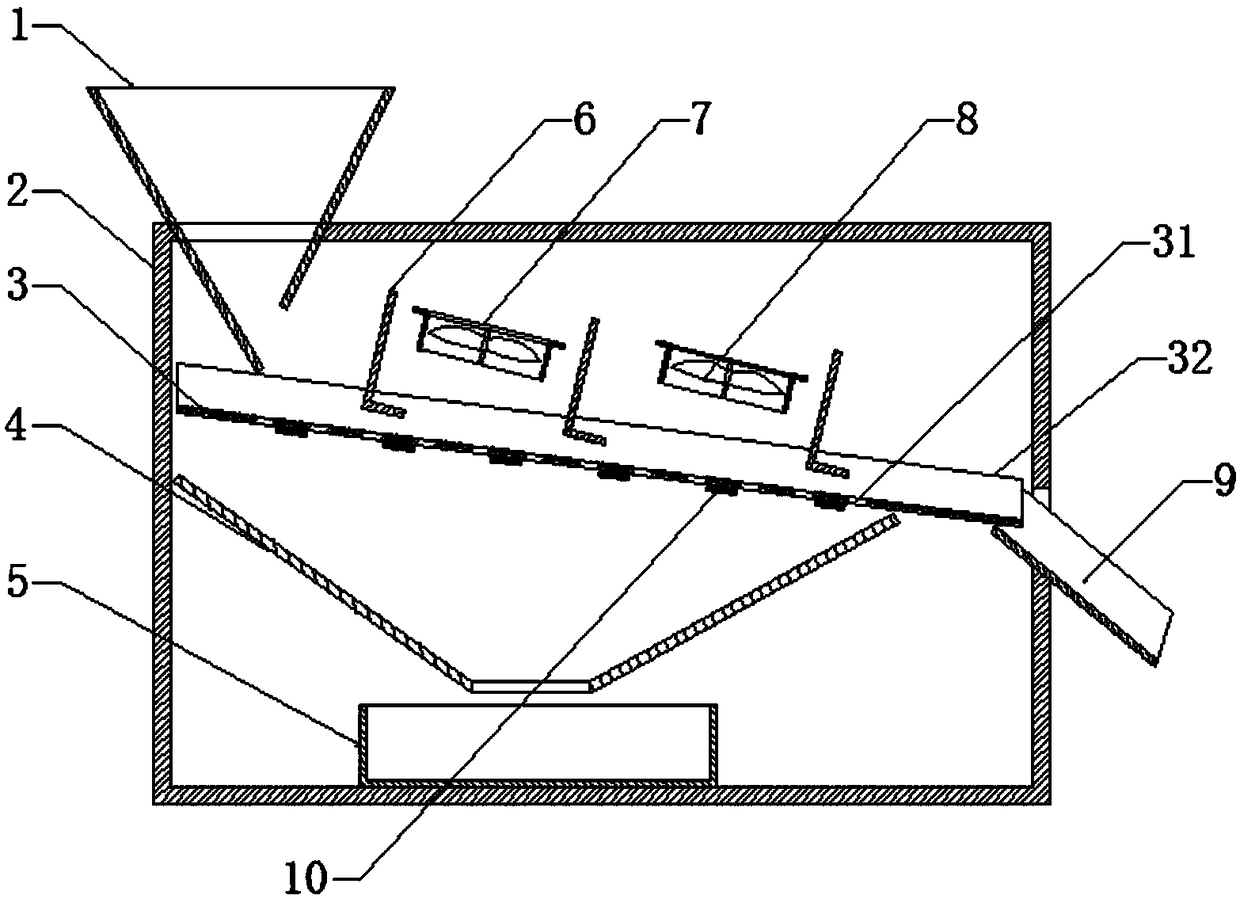

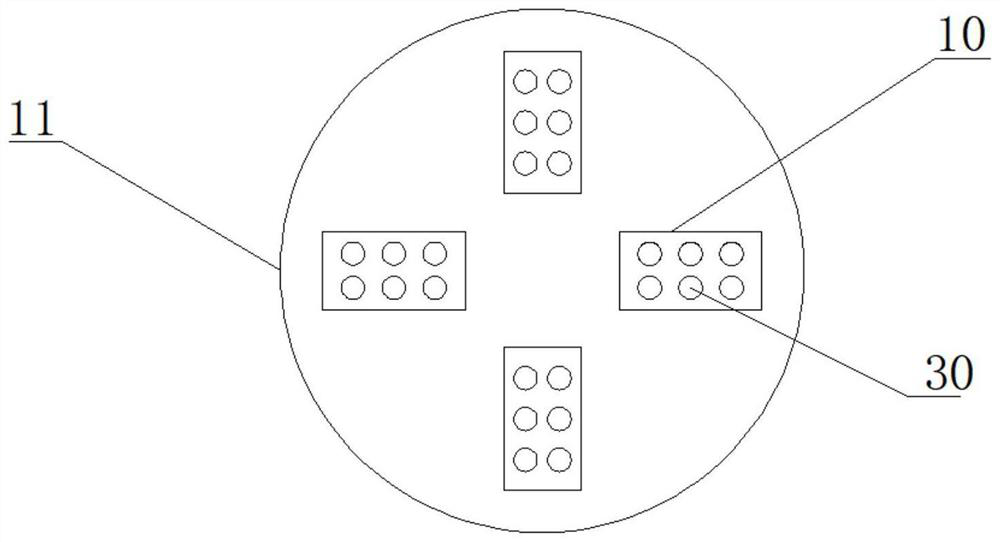

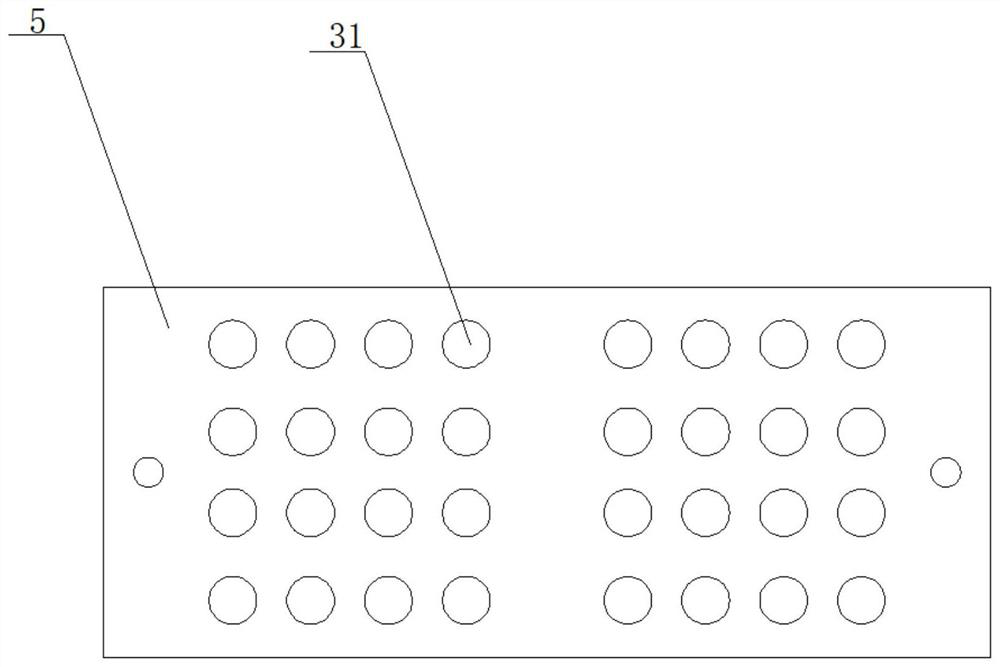

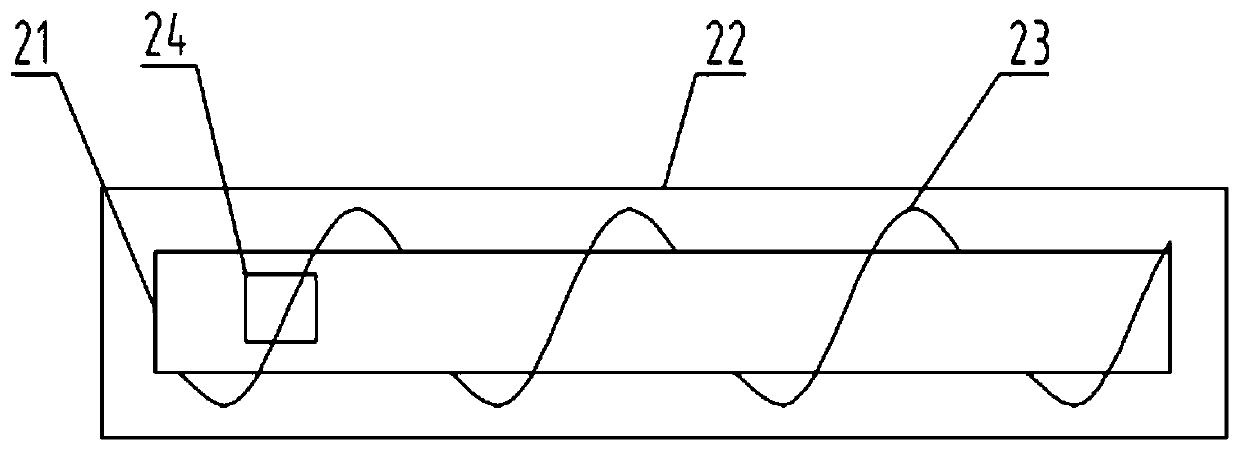

Negative-pressure pulse cooperated ordinary pressure radio-frequency spouted-bed drying device and application thereof

PendingCN108895767AImprove drying efficiencyReduce energy consumptionDrying solid materials with heatGranular material dryingRadio frequencyPoor quality

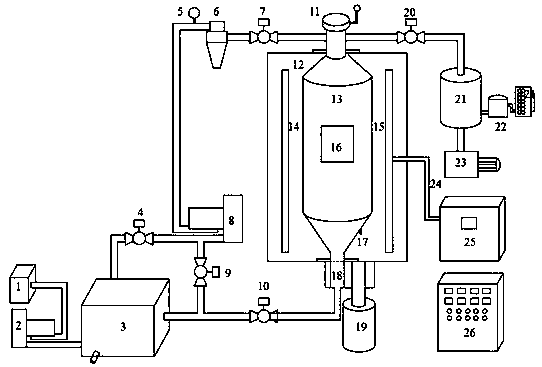

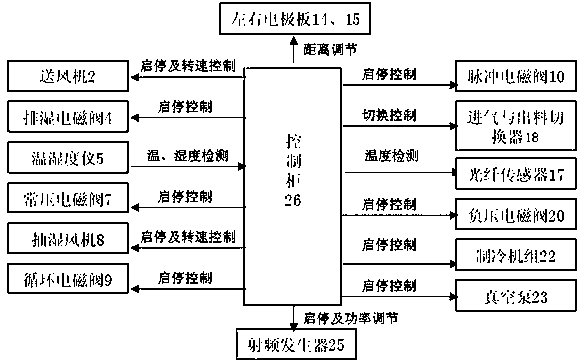

The invention provides a negative-pressure pulse cooperated ordinary pressure radio-frequency spouted-bed drying device and application thereof and belongs to the technical field of agricultural product and food drying and processing technologies and mechanical device manufacturing. The spouted-bed drying device makes a wet material arranged in a spouted bed heated between left and right electrodeplates under the effect of a radio-frequency field, material moisture is evaporated under the effects of an air blower and a dehumidification fan, and spatial motion and uniform dispersion of the material are achieved under the effect of negative-pressure pulse spouting. Tradition air drying is replaced by ordinary pressure radio-frequency spouted-bed drying, the wet material drying efficiency isimproved, the drying time is shortened, the drying power consumption is reduced, and the uniformity of dried products is improved. Uniform material dispersion is achieved by adopting negative-pressure pulse spouting, the problems such as adhesion, agglomeration, poor quality, time and effort waste and the like in the ordinary pressure drying process of high-adhesion materials are solved, energy is saved by 40% or above, the uniformity is improved by 90% or above, and ordinary pressure efficient energy-saving and high-quality drying of agricultural products and foods is achieved.

Owner:JIANGNAN UNIV +2

Environment-friendly material stirring device with dustproof function

InactiveCN108745102AQuick sealAvoid pollutionRotary stirring mixersTransportation and packagingEngineeringSolar heat

The invention discloses an environment-friendly material stirring device with a dustproof function. The environment-friendly material stirring device comprises a scraping plate, a brush, solar heat collection plates, a stirring tank and a base. The environment-friendly material stirring device has the advantages that the scraping plate is used for scraping materials adhered on the inner wall of the stirring tank, accordingly, effects of stirring materials can be guaranteed, and wastage of the materials can be prevented; effects of scraping the materials adhered on the inner wall of the stirring tank further can be improved by the brush, and accordingly the practicality of the environment-friendly material stirring device can be improved; the solar heat collection plates are used for absorbing solar energy, and accordingly air in a heat-insulation cover can be heated; external air can flow into a filter tank by the aid of an exhaust fan and can be heated by the aid of the solar heat collection plates, accordingly, energy can be saved, and environments can be protected; air in a cavity further can be exhausted via a gas outlet pipe, accordingly, hot air in the cavity can be continuously circulated, the purposes of continuously heating and drying the materials in the stirring tank further can be achieved, and the practicality of the environment-friendly material stirring device further can be improved.

Owner:张梅梅

Wood drier

InactiveCN107255397ASimple structureEasy to operateDrying chambers/containersDrying machines with non-progressive movementsEngineeringCentrifugal fan

The invention discloses a wood drier. The wood drier comprises a cylindrical barrel, a heating device, a screen, a centrifugal fan and a frame, wherein a feeding door is formed in one side of the barrel, and the barrel is filled with heat conducting media; the heating device is arranged at the bottom of the barrel and used for heating the barrel; the screen and the centrifugal fan are arranged on the other side of the barrel, and the centrifugal fan is located outside the screen; and a hinging shaft is arranged on one side of the frame, a bracket is arranged on the other side of the frame, the bracket is in the shape of a semicircle with the diameter matched with that of the barrel, one side of the feeding door of the barrel is connected to the hinging shaft, and the bracket supports the other side of the barrel. The wood drier can dry wood and is simple in structure, convenient to operate and reliable in use.

Owner:芜湖斯塔克智能科技有限公司

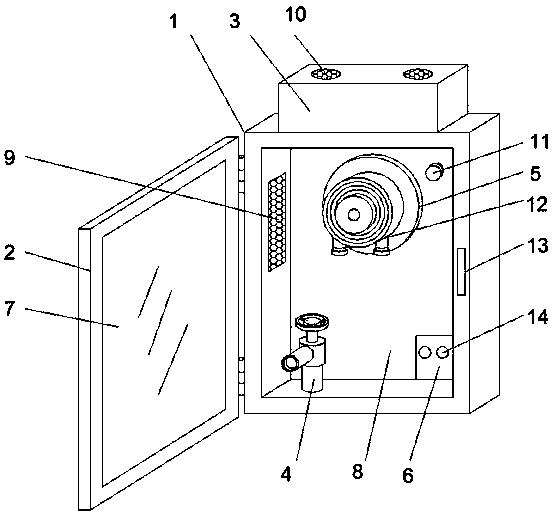

Indoor fire extinguishing device with dehumidification function

InactiveCN109603062AEasy to storePrevent rustDispersed particle separationFire rescueReducerEngineering

The invention provides an indoor fire extinguishing device with dehumidification function. The device comprises a cabinet body, a cabinet door, a dehumidification device, a fire hydrant, a wrap-up device and a control box. The cabinet door is connected to the cabinet body in hinge mode with a hinge, The upper end of the cabinet body is provided with a dehumidification device. Through the arrangement of the wrap-up device and through the connection of a rotary shaft of the wrap-up device and the motor by a reducer, water hoses can be stored conveniently; and through the arrangement of the dehumidification device and the arrangement of a heating plate in the dehumidification device, the device can achieve heating and drying inside of the cabinet body, and can avoid rusting of the fire hydrant and corruption of the water hoses to ensure service life of the device.

Owner:XIAN XINGYI TECH

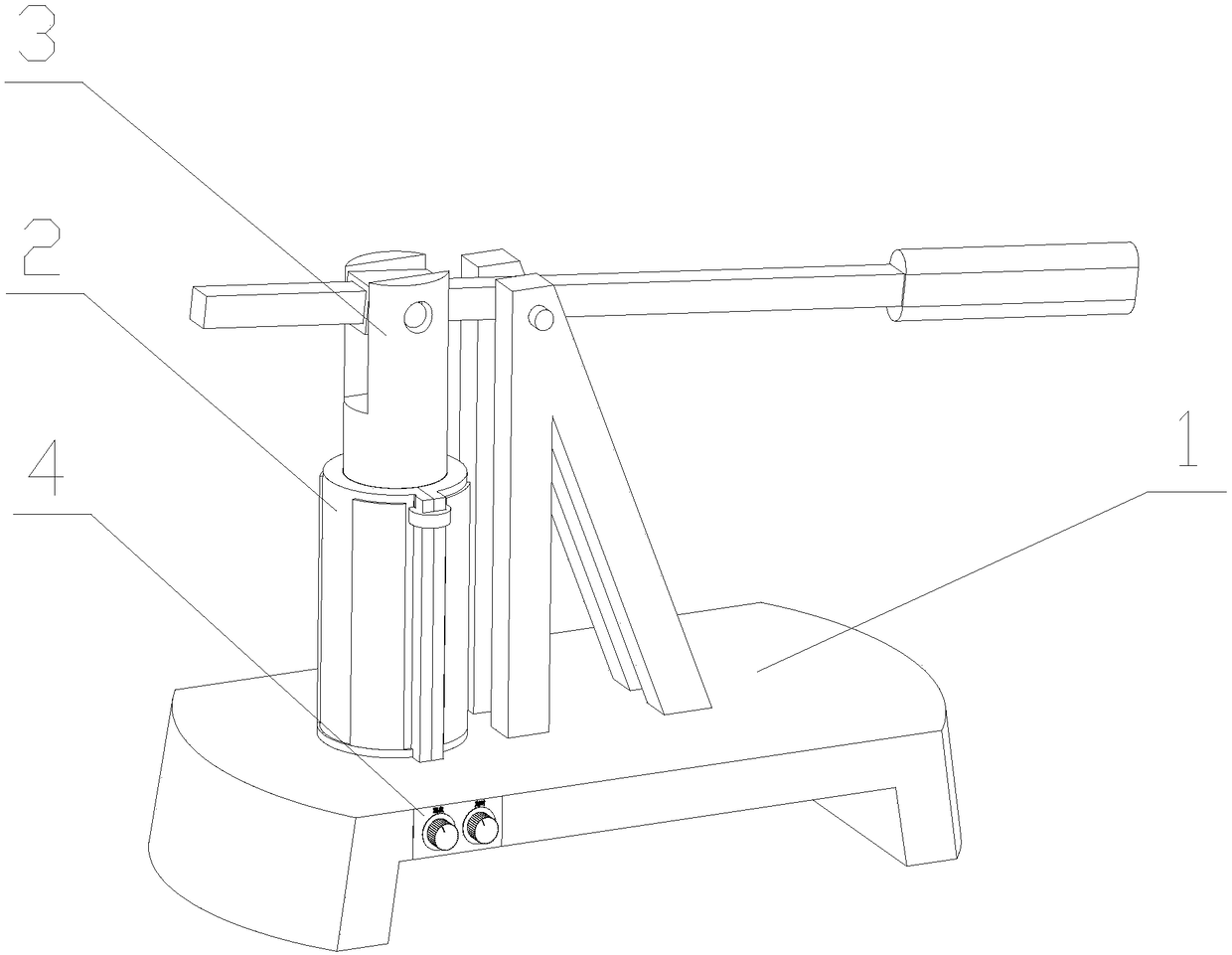

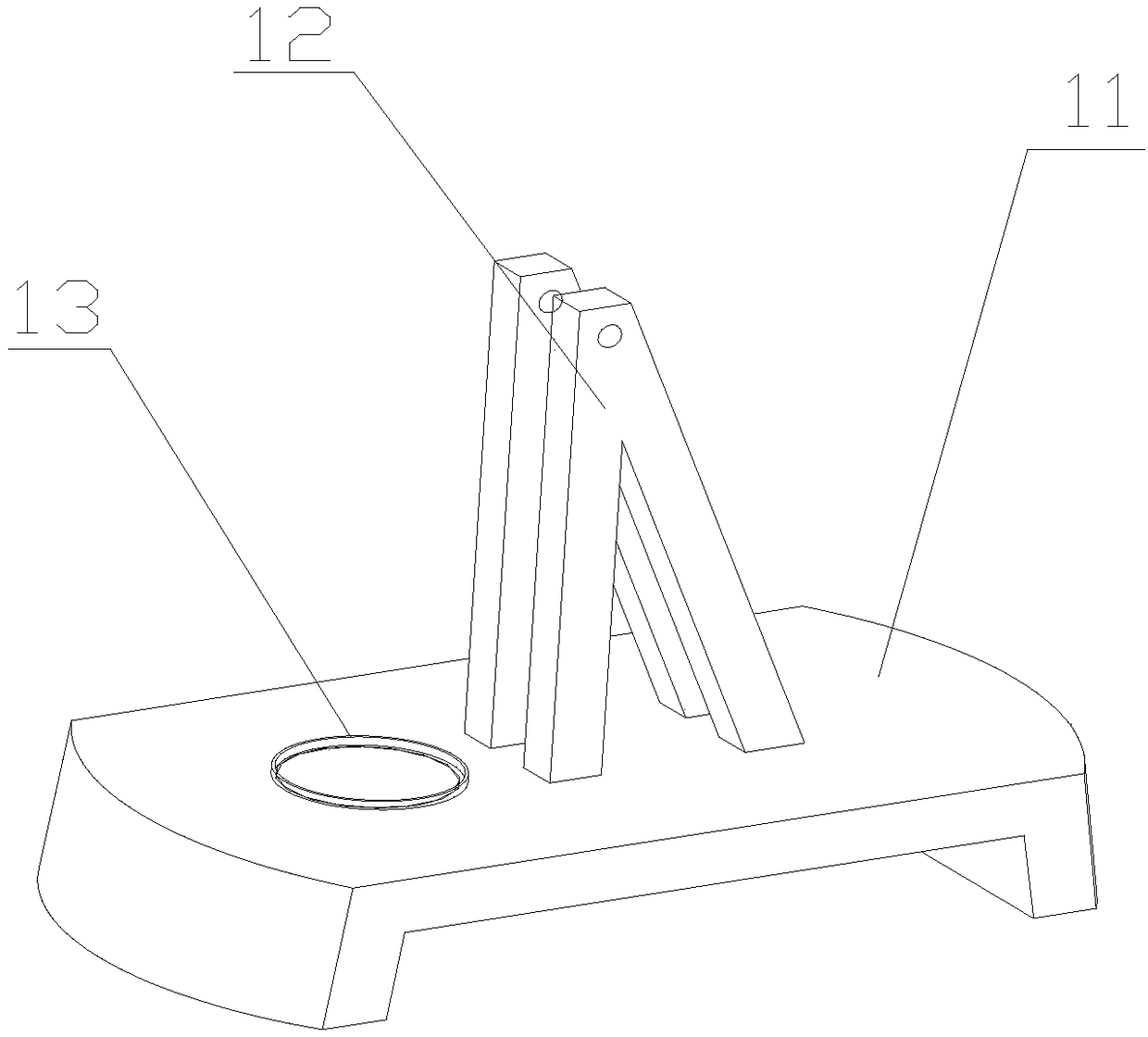

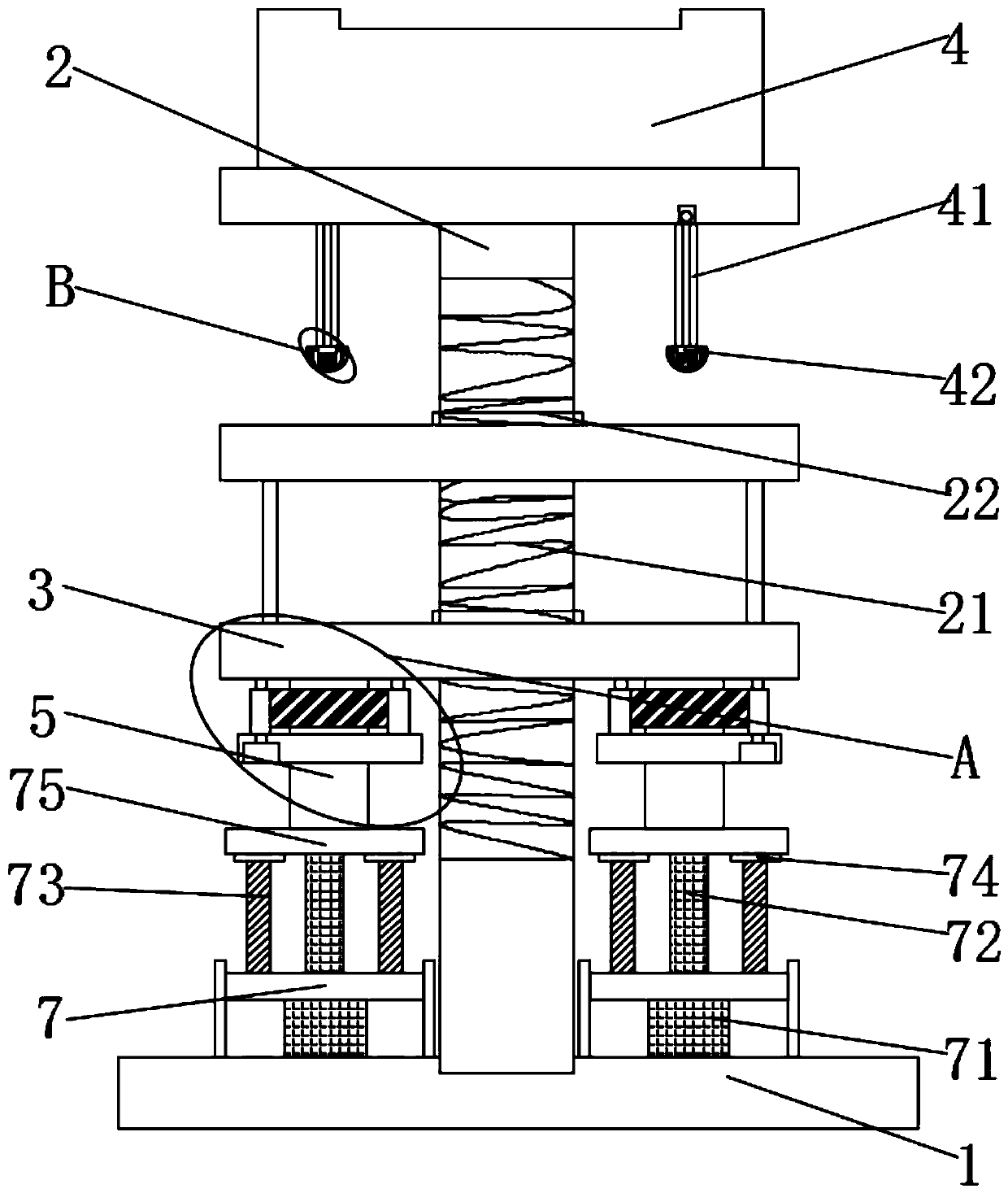

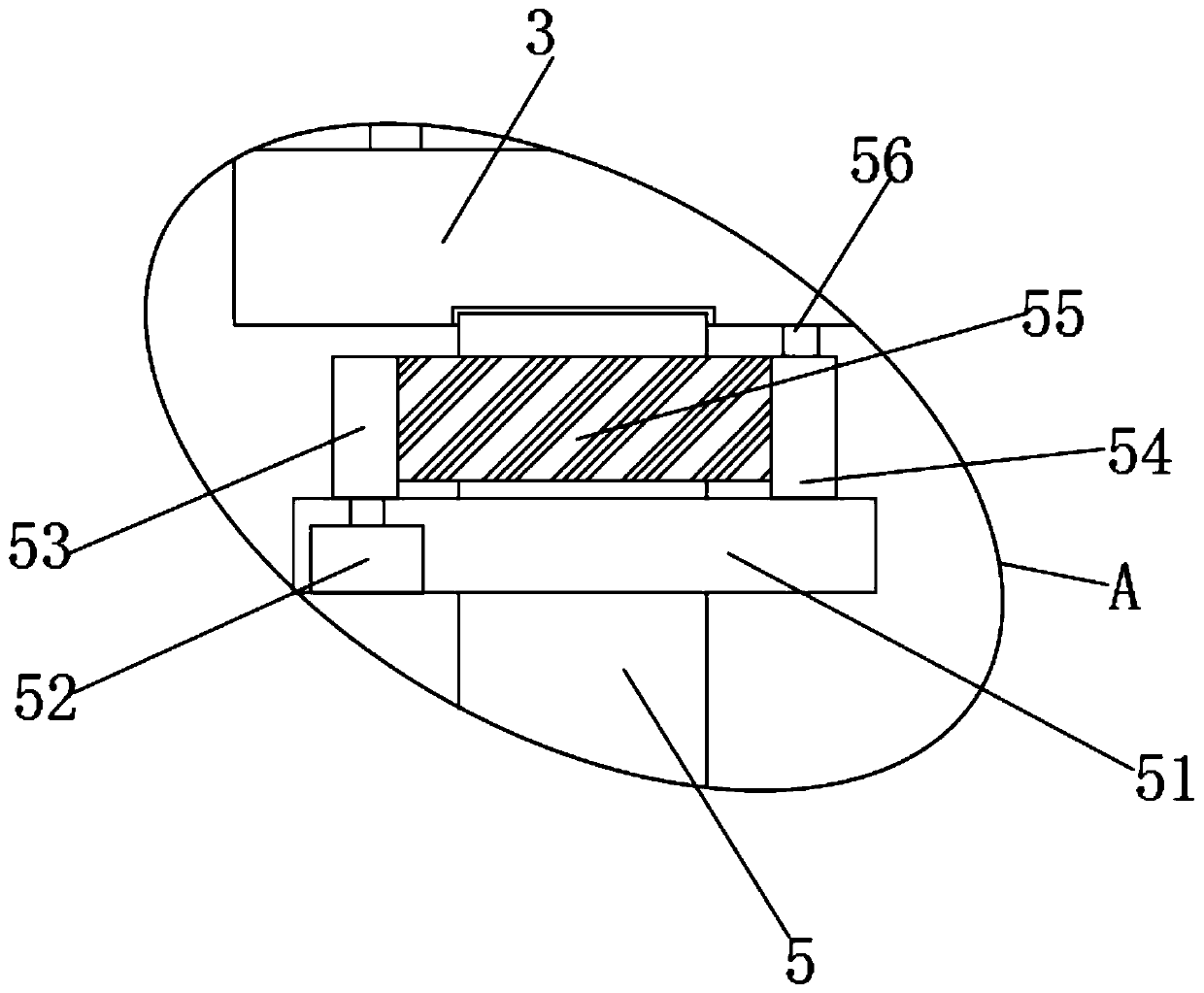

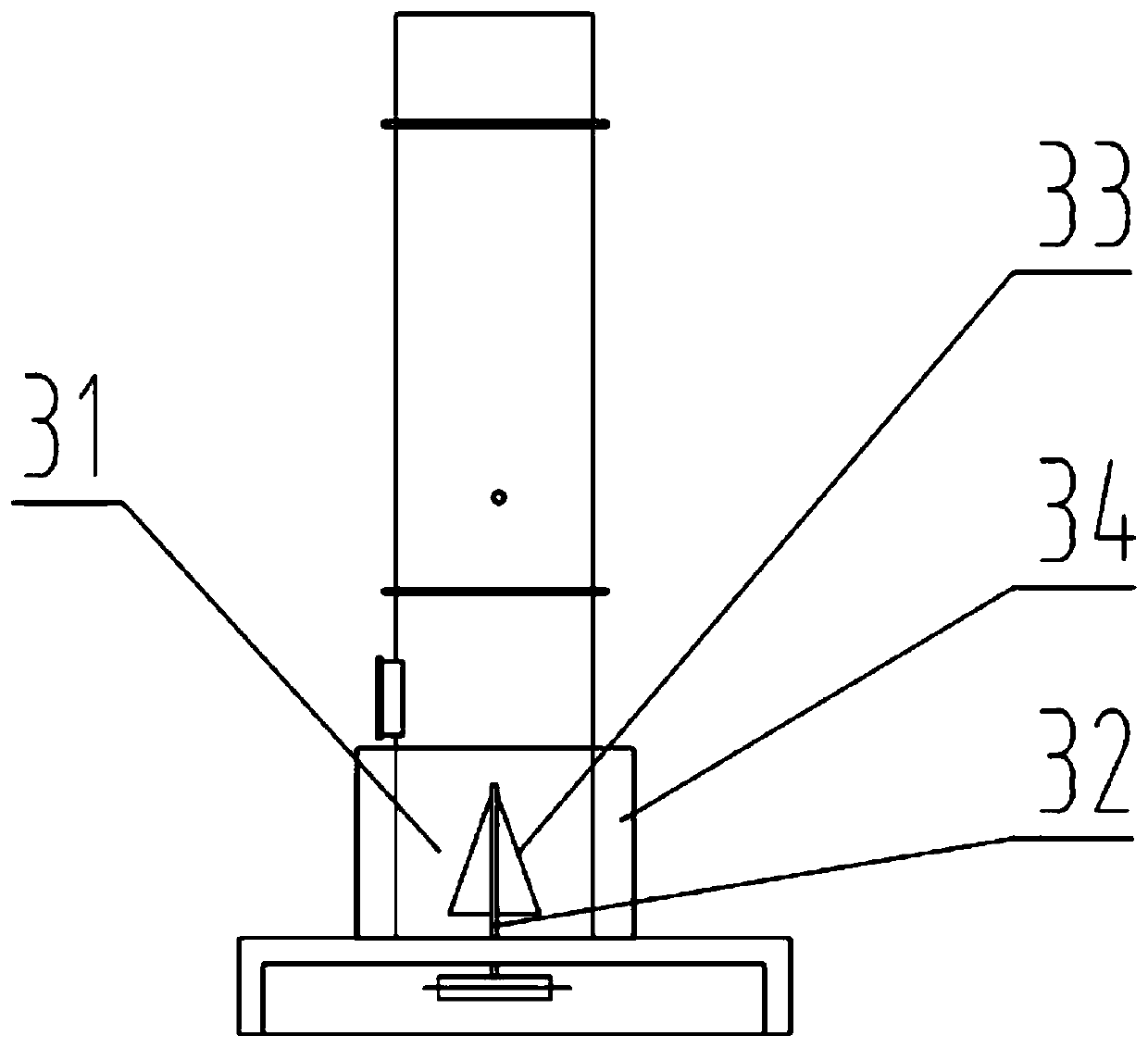

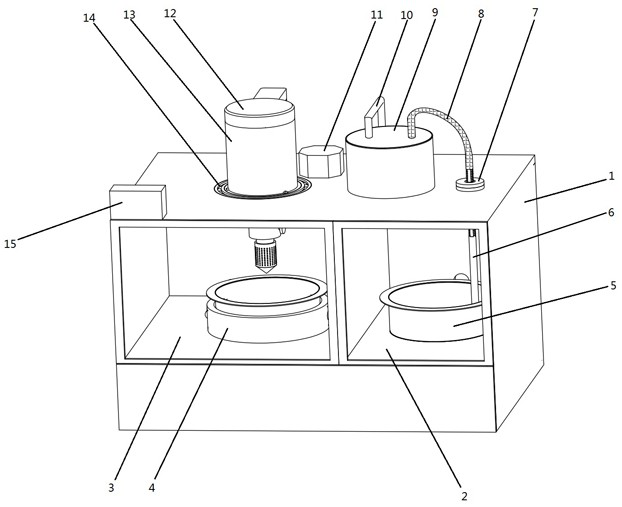

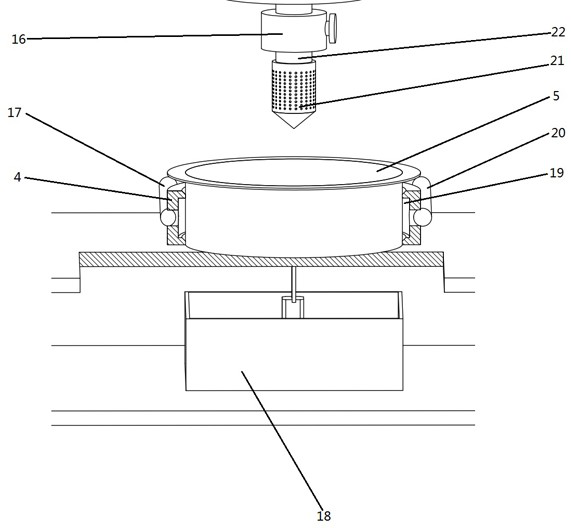

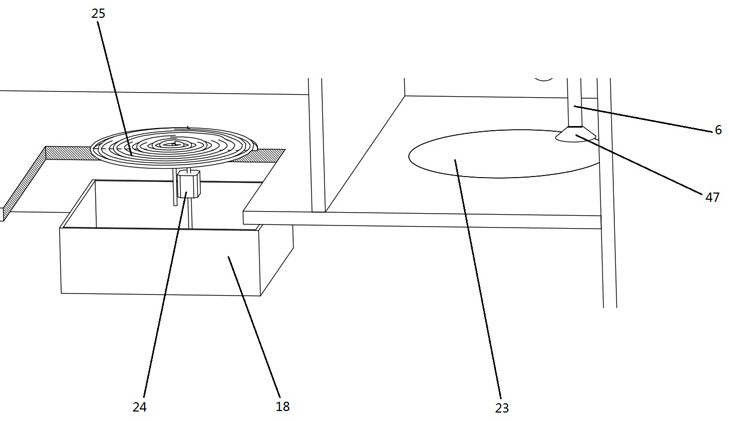

Device for producing cylindrical test piece for rock and soil test

InactiveCN109470536AAchieve supportAchieve fixed supportPreparing sample for investigationTemperature controlEngineering

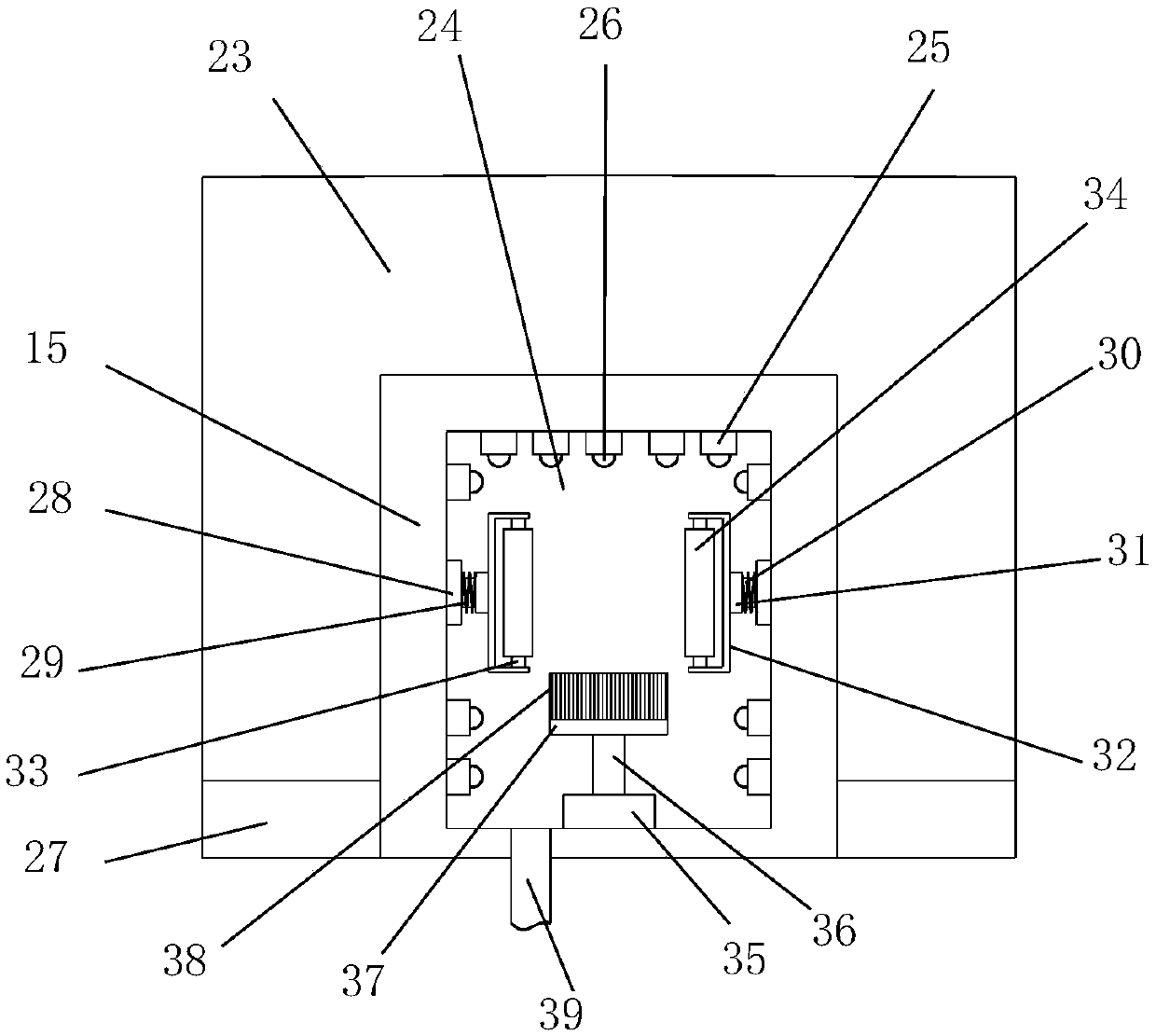

The invention discloses a device for producing a cylindrical test piece for a rock and soil test, aims to achieve rapid production of the cylindrical test piece for the rock and soil test through a lever compacting device and an electric heating matched mould device integrating electric heating sheets, overcomes the defects of high labor consumption, long drying time, low production efficiency andthe like during the conventional smashing hammer knocking compaction, and achieves test piece production with high efficiency and low labor consumption. The device for producing the cylindrical testpiece for the rock and soil test comprises a machine frame device, the electric heating matched mould device, the lever compacting device and a timing and temperature control device. The device for producing the cylindrical test piece for the rock and soil test is convenient to operate and easy to maintain, and has a broad application prospect in the production of rock and soil test pieces.

Owner:QINGDAO UNIV OF SCI & TECH

Drying device with storage battery electrode plate surface dust removing function

InactiveCN108613517AOrderly snapping and fixingEasy to take outDrying gas arrangementsDrying chambers/containersSurface cleaningSpray nozzle

The invention discloses a drying device with a storage battery electrode plate surface dust removing function. The drying device comprises a main shell, a heating shell, a base, heating pipes, a draught fan, an air inlet pipe, air spraying nozzles, an air inlet cover, an air outlet pipe, a connecting pipe, air spraying heads, a fixing plate, a handle, clamping blocks, clamping plates, electrode plate clamping grooves, a movable plate, brushes, a fixing column, an exhaust pipe, connecting plates, springs, a rotary disc, a motor, a first rack and a second rack. The drying device with the storagebattery electrode plate surface dust removing function is simple in structure, electrode plates are conveniently clamped and fixed in order, the cleaned and dried electrode plates are conveniently taken out, operation is relatively simple, and the efficiency of taking-out of the electrode plates through a worker is improved. During usage, the opposite surfaces of the electrode plates are dried and cleaned at the same time, cyclic cleaning is conducted on the surfaces of the electrode plates, the labor intensity of manual electrode plate cleaning is relieved, the electrode plate surface cleaning and drying efficiency is improved, and the electrode plate surface cleanliness is guaranteed.

Owner:NANJING CHUQING ELECTRONICS TECH CO LTD

Baking and hardening device for bamboo furniture raw material processing

InactiveCN110726301AScientific and reasonable structureEasy to useDrying machines with progressive movementsDrying solid materialsElectric machineryMechanical engineering

The invention discloses a baking and hardening device for bamboo furniture raw material processing. The baking and hardening device comprises a box body, a heating plate and second conductors; the heating plate is arranged on the left side of the lower part of the inner wall of the box body; the left and right sides of the heating plate are separately connected to an external power through the second conductors; the rear side of a first rotary shaft on the right end is fixedly connected to an output shaft of a motor; the outer wall of the rear side of a first rotary shaft on the left side is fixedly connected with a roller; and the front and rear sides of the first rotary shafts are separately rotatably connected to a first horizontal plate and the box body through bearings. The baking andhardening device for bamboo furniture raw material processing is scientific and reasonable in structure and safe and convenient to use; a driving device is arranged, and through cooperation among themotors, the gears, a rack, the first rotary shafts, the heating plate, the rollers and bamboo pipes, the bamboo pipes can be heated and baked by starting the motors and the heating plate; meanwhile,hardening processing is realized through rotating; and the problem that bamboo furniture baking efficiency is low is solved.

Owner:泰宁县青竹竹制品有限公司

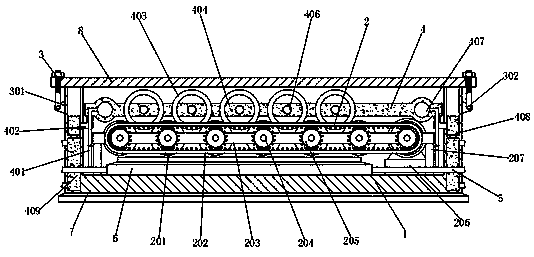

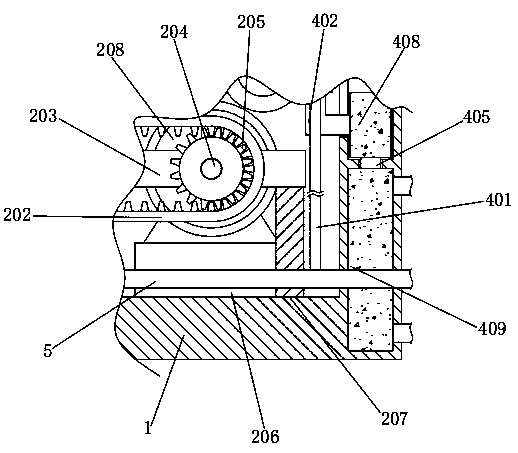

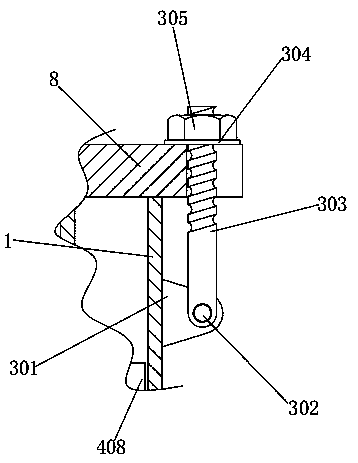

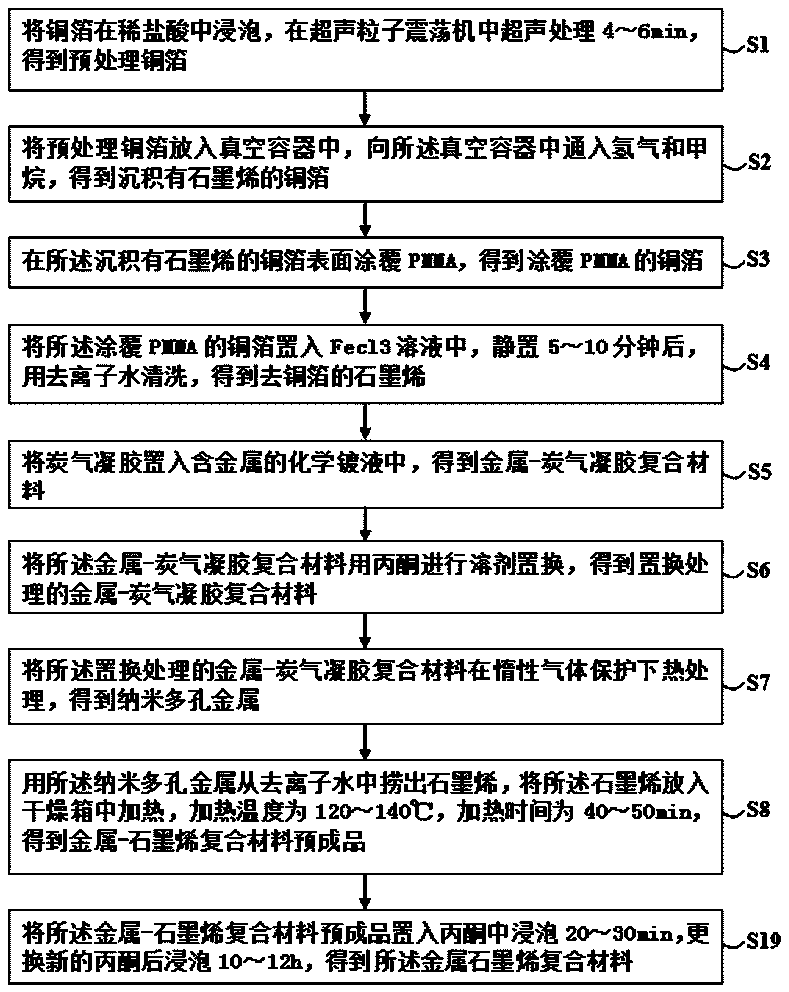

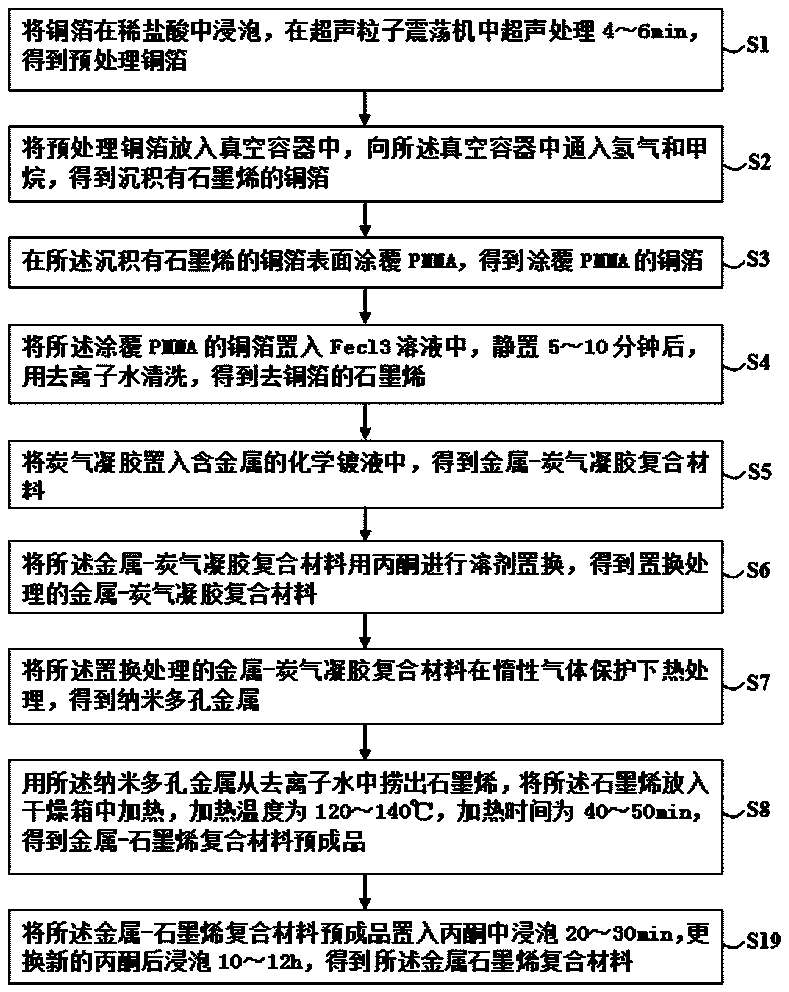

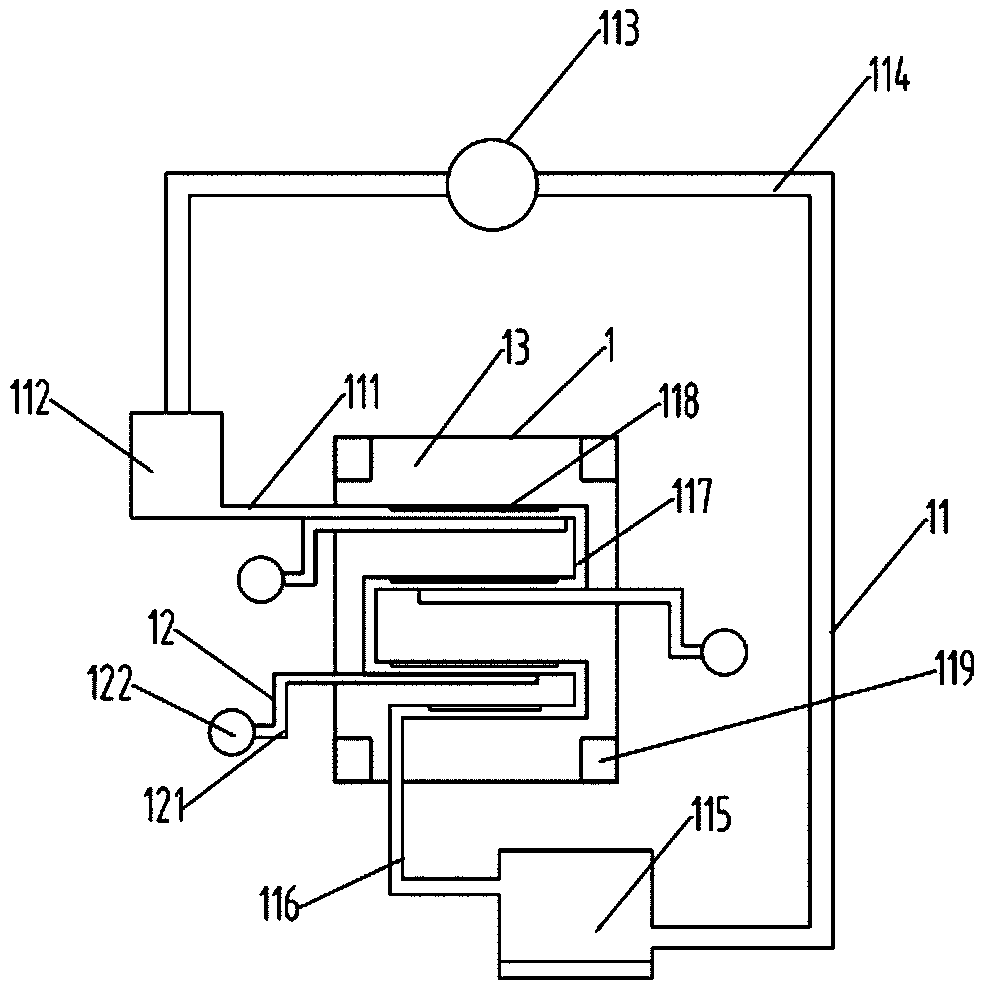

Metal graphene composite as well as preparation method and device thereof

ActiveCN109161715AIncrease productivityImprove electrode performanceGrapheneChemical vapor deposition coatingChemical platingCopper foil

The invention discloses a metal graphene composite as well as a preparation method and device thereof. The composite is prepared from the following raw materials: copper foil, dilute hydrochloric acid, hydrogen, methane, PMMA, a FeCl3 solution, deionized water, carbon aerogel, a metal-containing chemical plating solution, acetone and inert gas. The preparation method comprises the following steps:preparing nano porous metal, fishing out graphene from deionized water by using the nano porous metal, and placing the graphene into a drying oven for heating to obtain the metal graphene composite.According to comparison between graphene with metal support and graphene without metal support by experiments, metal graphene prepared with the preparation method of the metal graphene composite has the advantages that graphene with metal support has obviously improved specific capacity and better electrochemical performance, and has better effect as an electrode of a supercapacitor.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

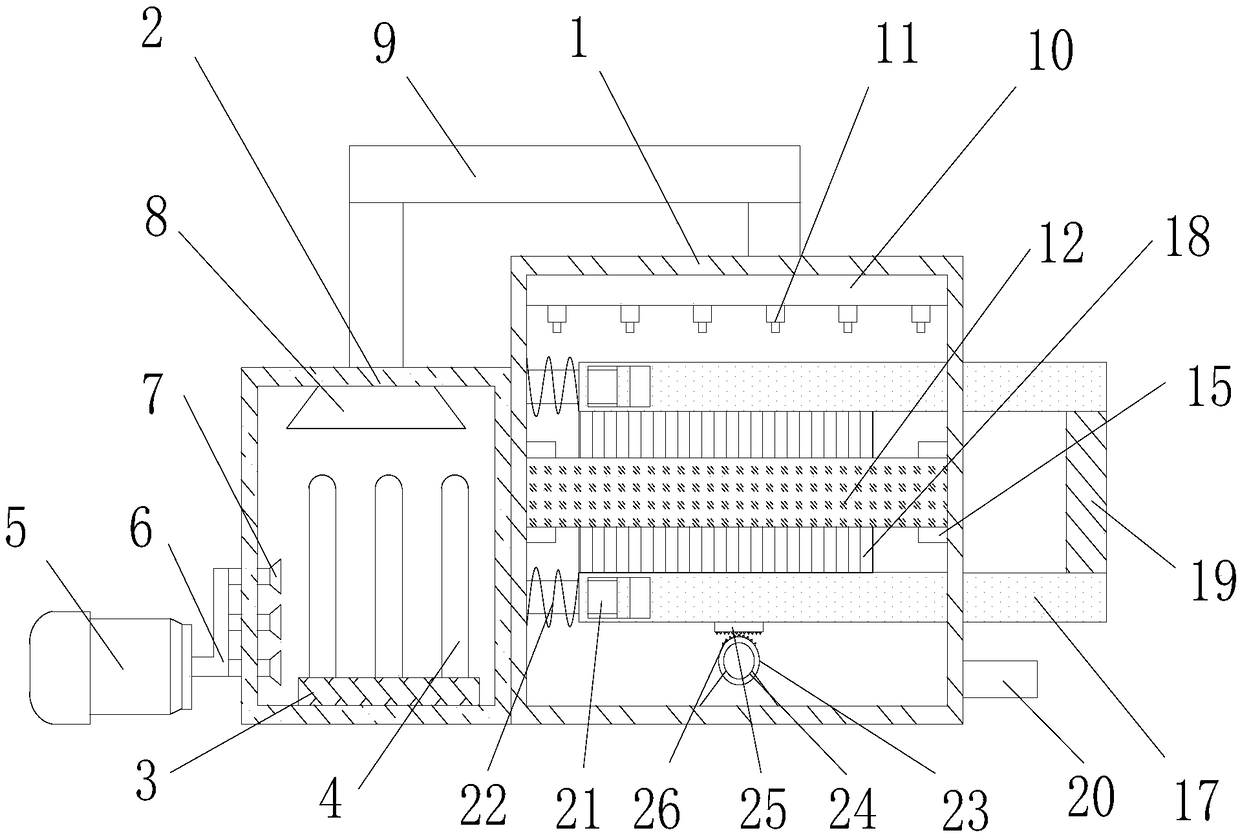

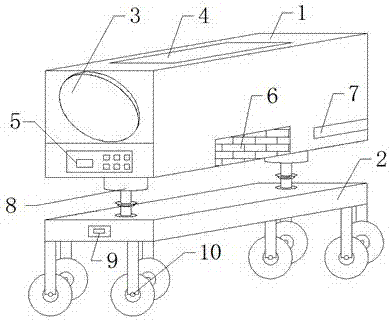

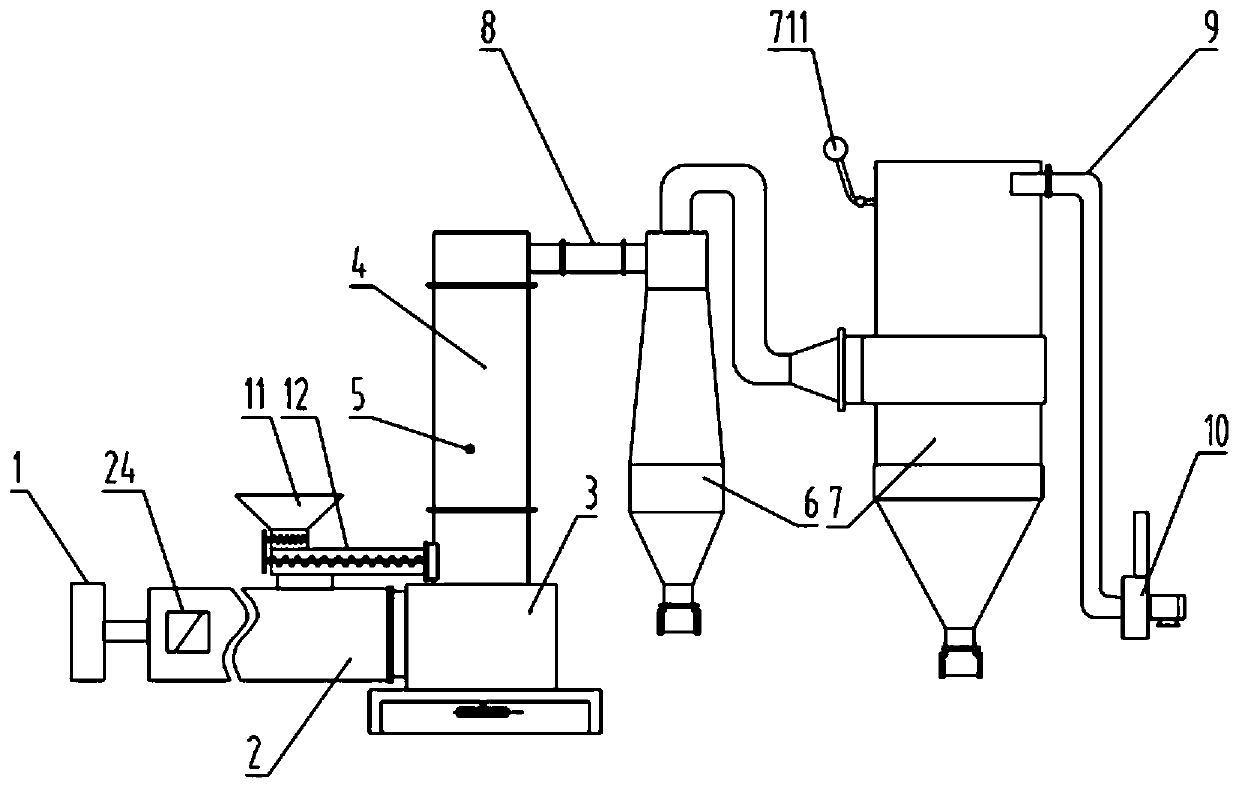

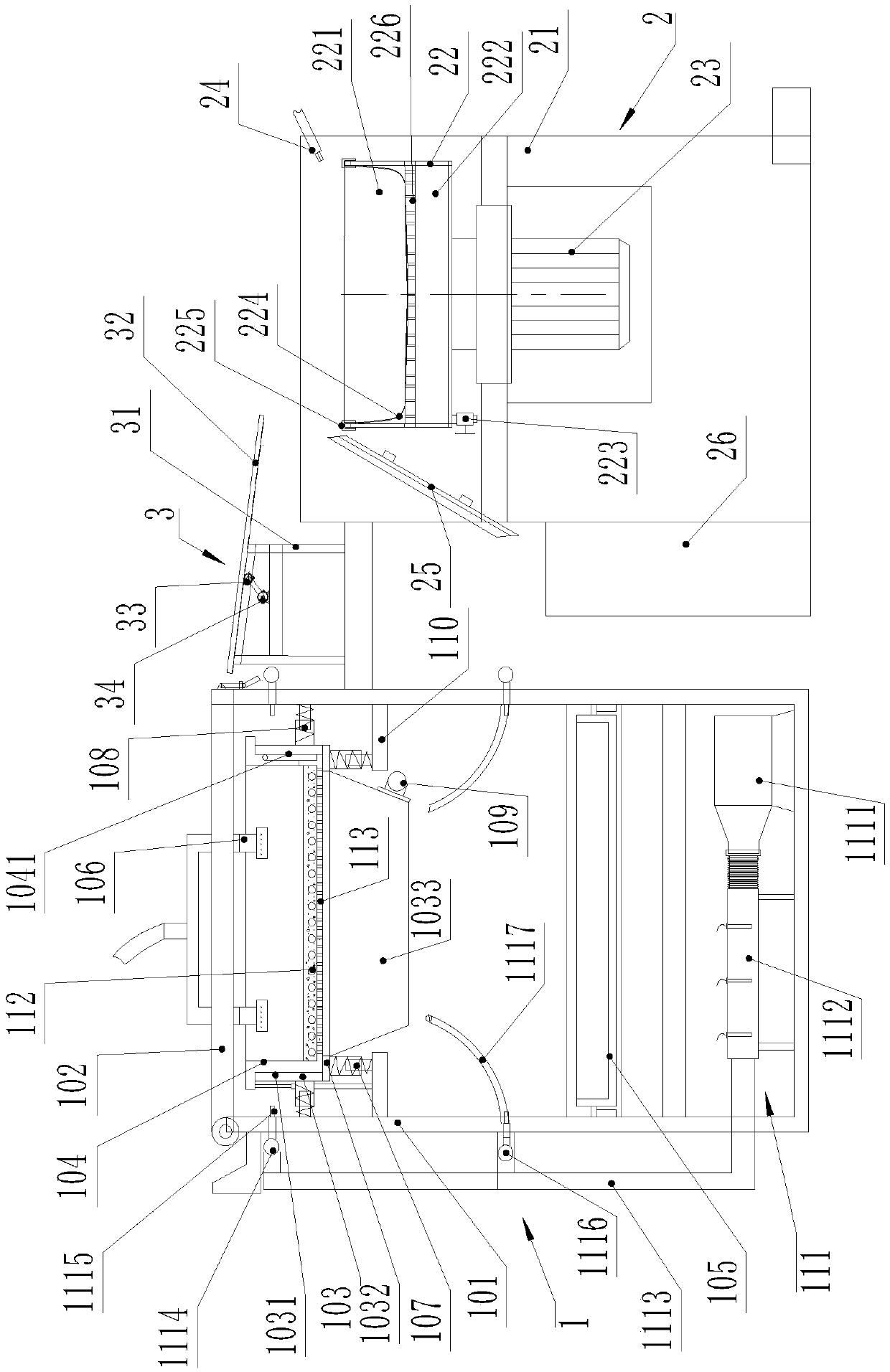

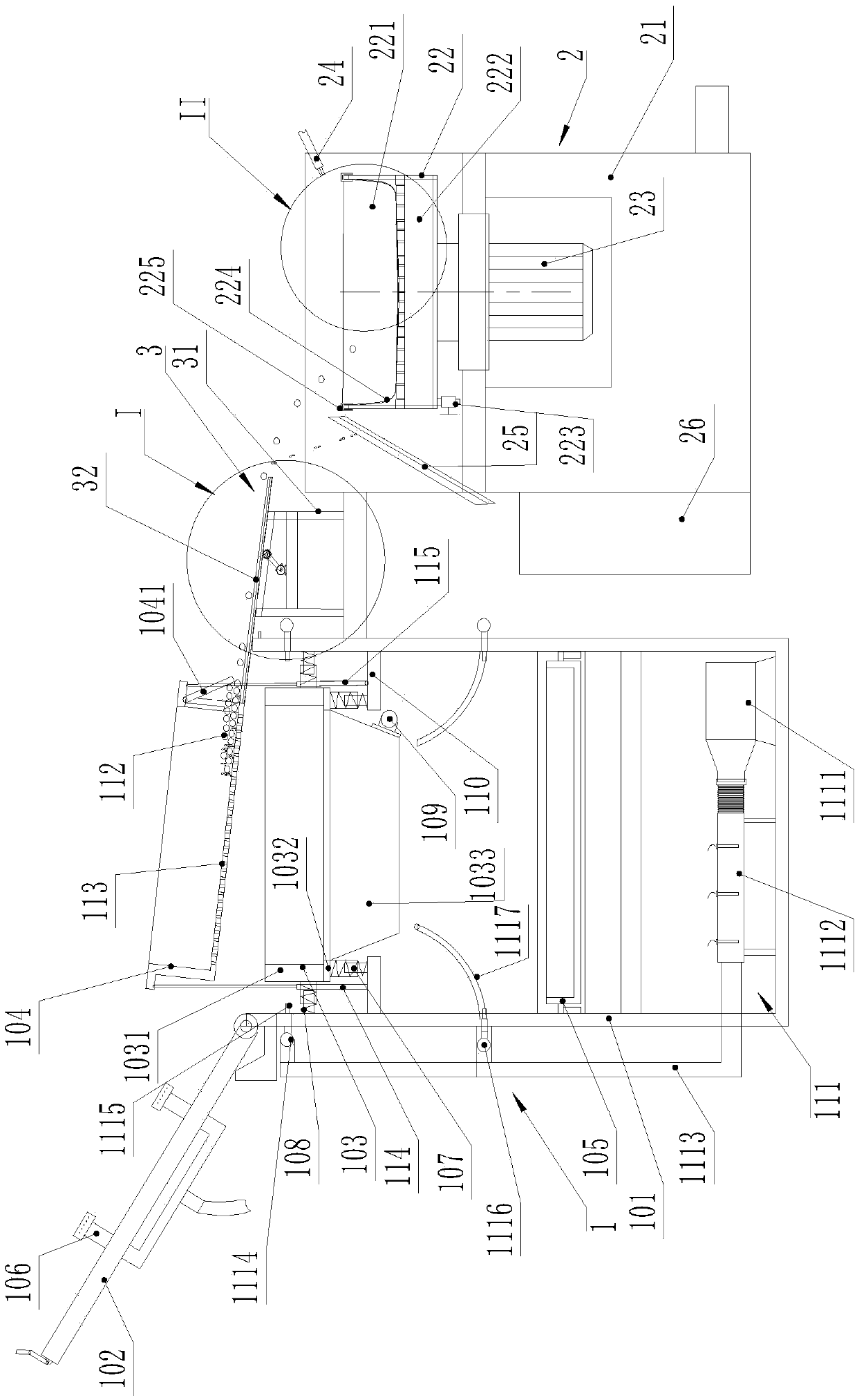

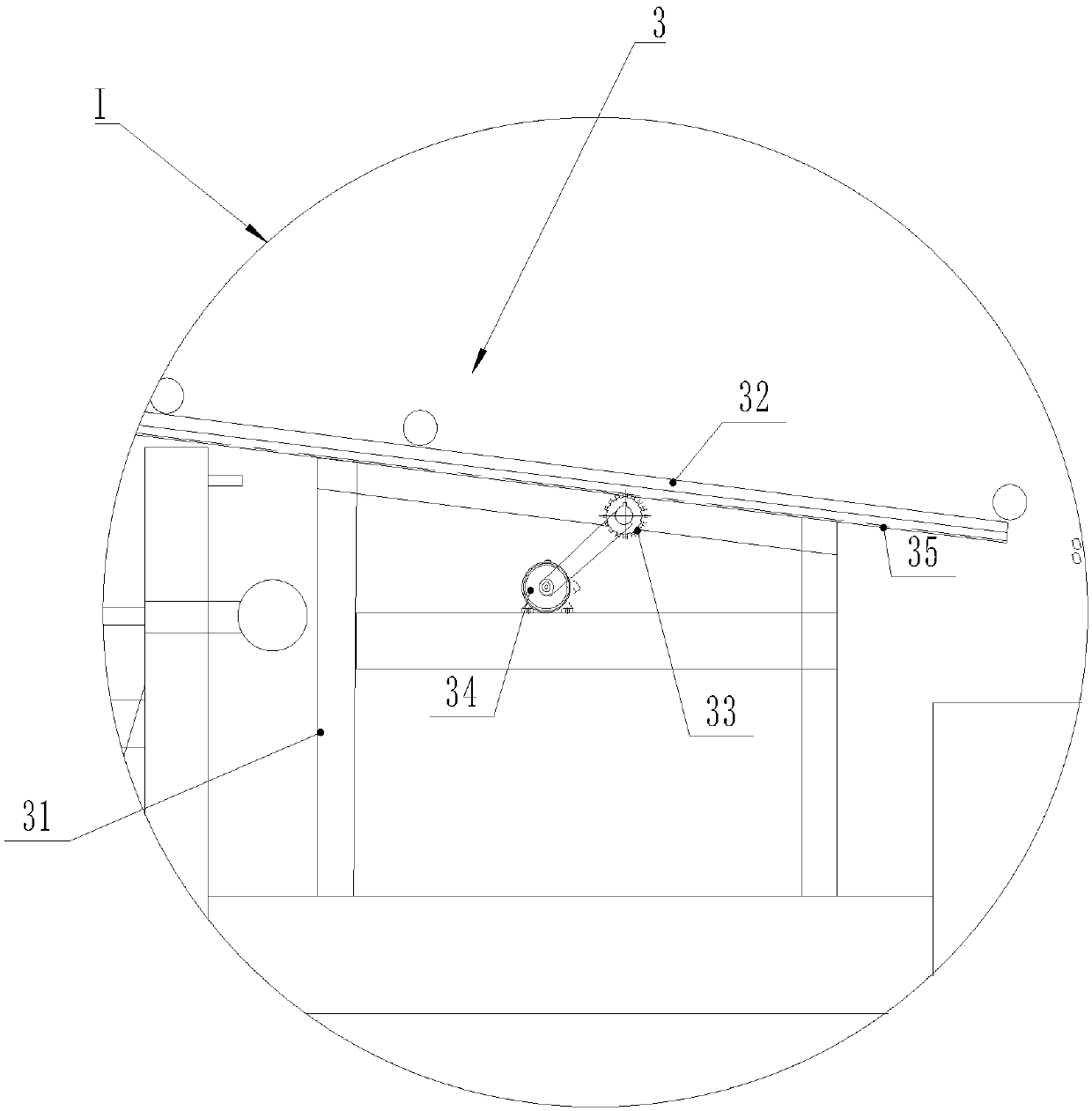

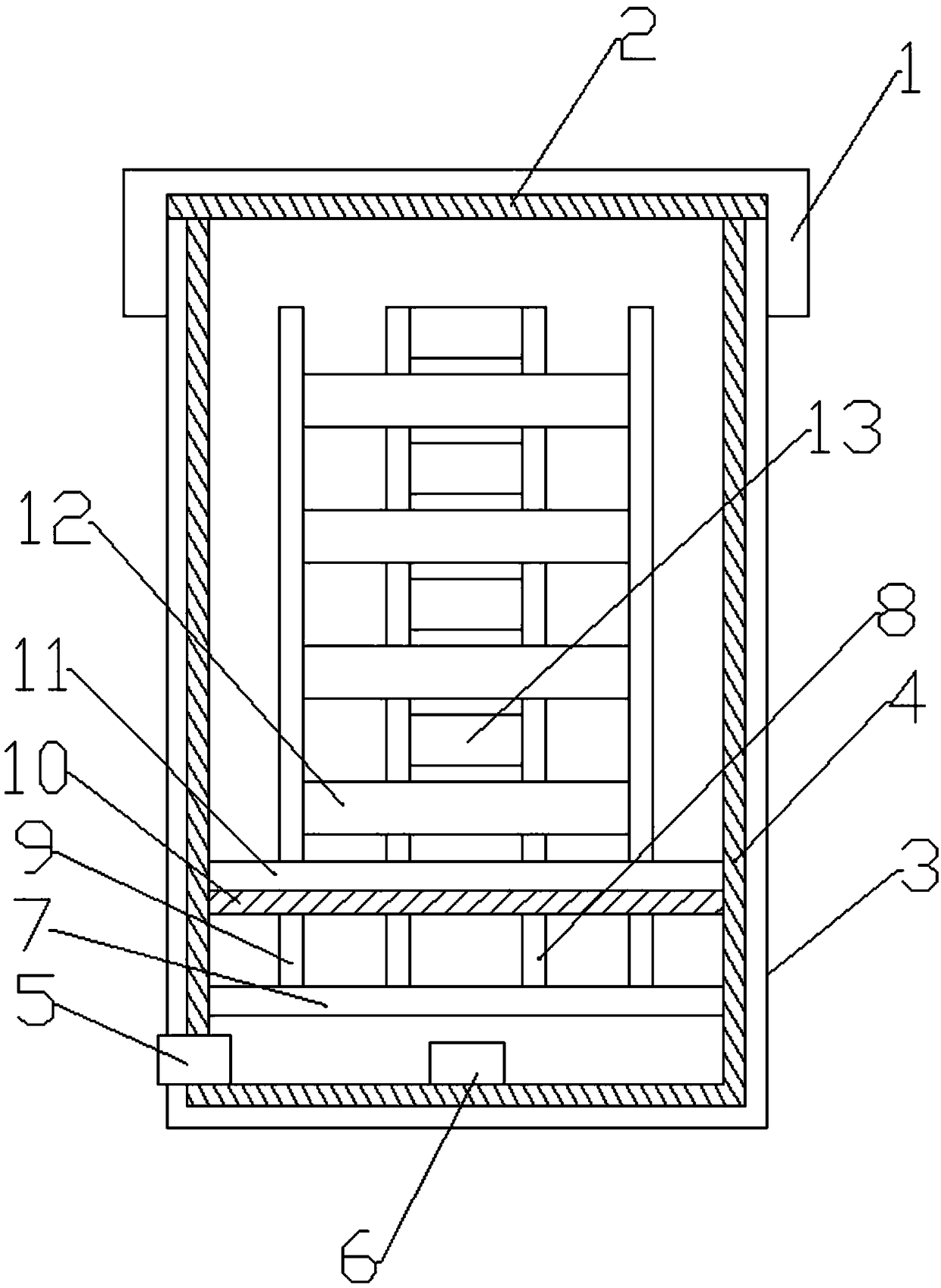

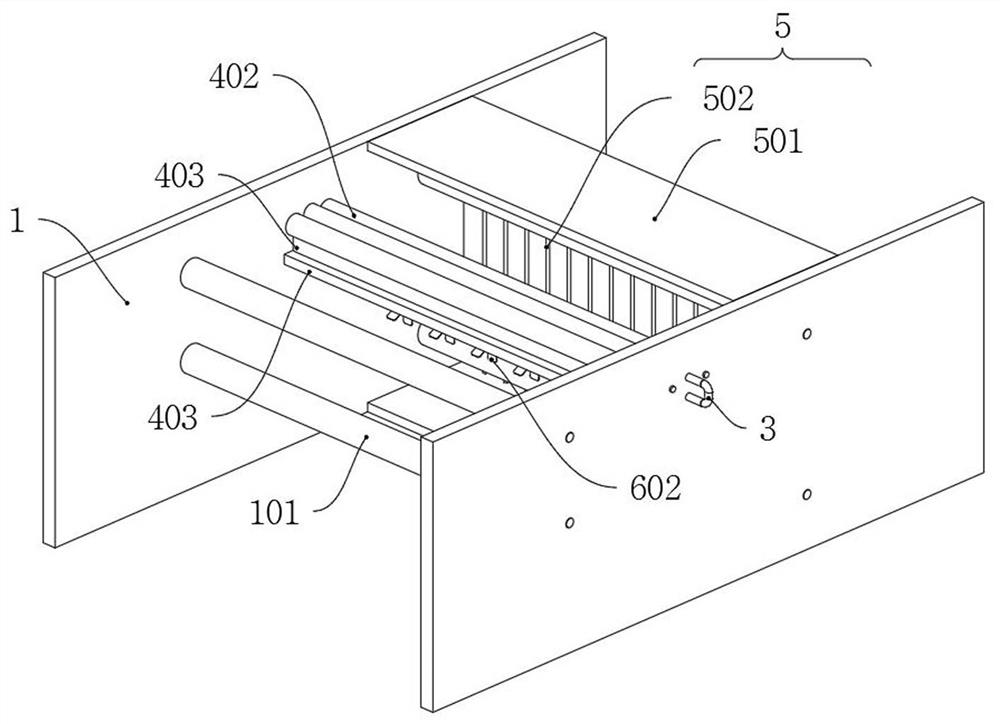

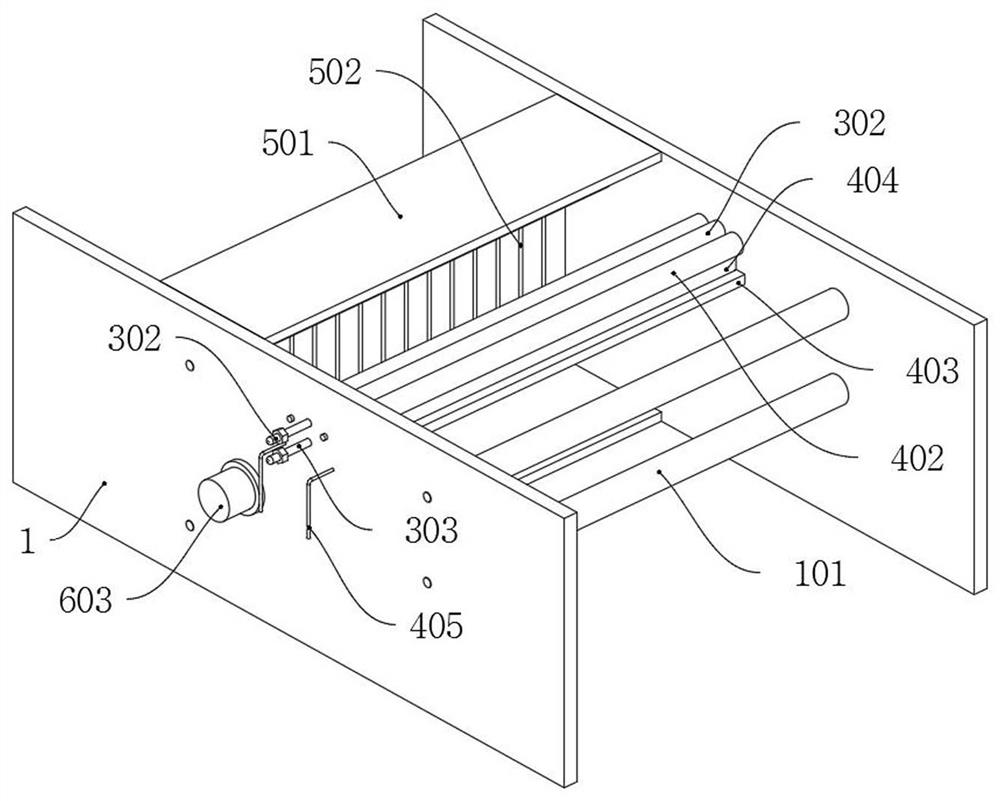

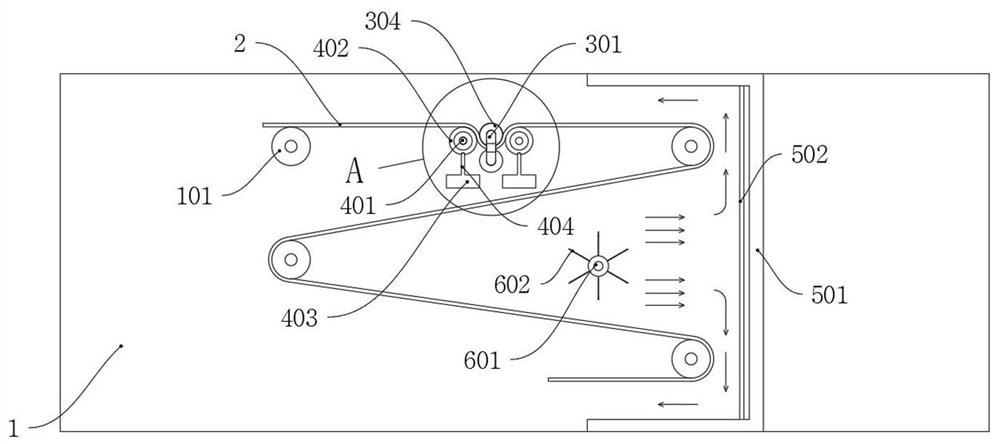

Drying device for aquatic feed production

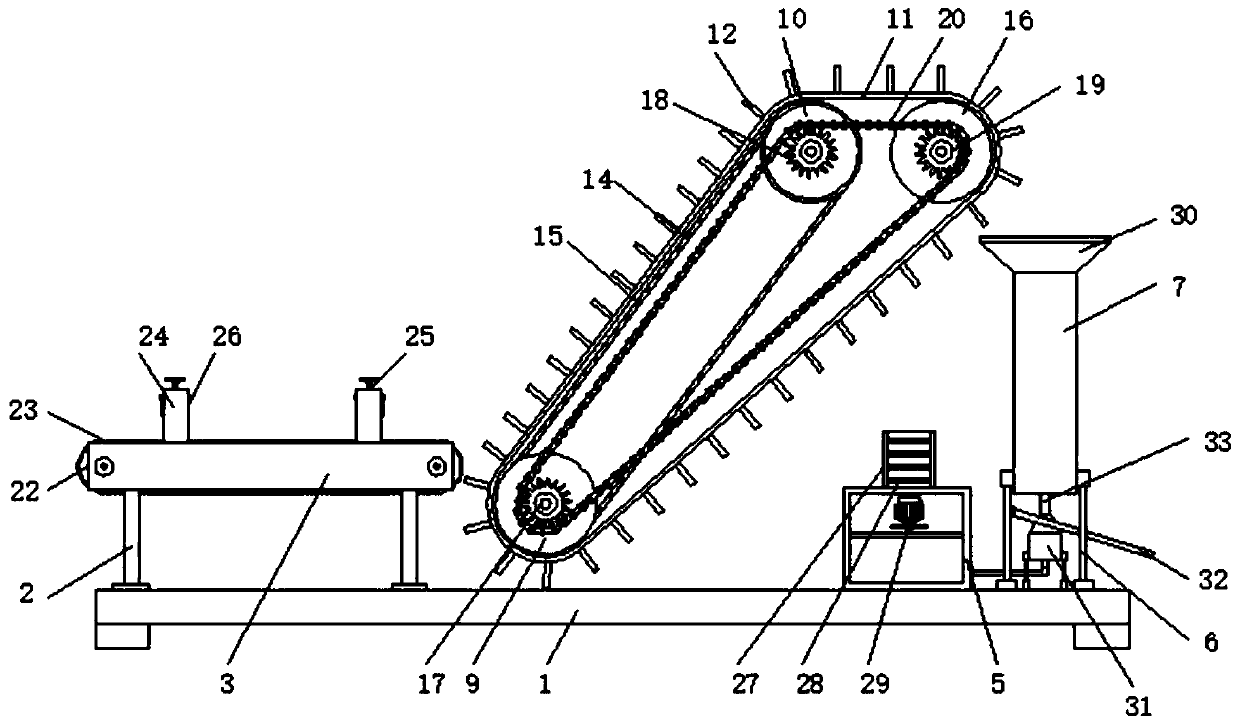

PendingCN111023781ARealize heating and dryingEnsure Structural IntegrityDomestic cooling apparatusDrying gas arrangementsProcess engineeringBiology

The invention relates to a drying device for aquatic feed production. The drying device comprises a base, a first supporting leg is fixedly connected to the top of the base through bolts, a conveyor body is fixedly connected to the top of the first supporting leg through bolts, an elevator body, an air box and a second supporting leg are fixedly connected to the position, close to one sides of thefirst supporting leg, of the top of the base through bolts, and the elevator body is located between the first supporting leg and the air box. According to the drying device for aquatic feed production, through synchronous movement of a lifting belt and a conveying belt, heat generated by work of an electric heating pipe makes full contact with aquatic feed, heating drying of the aquatic feed andconveying heating drying of the aquatic feed are achieved, on one hand, the problem that feed particles are broken due to traditional turning and drying is avoided, and the structural integrity of the aquatic feed is effectively guaranteed; and on the other hand, the drying efficiency is effectively improved, and conveying and drying integration is achieved.

Owner:山东美高美生物科技有限公司

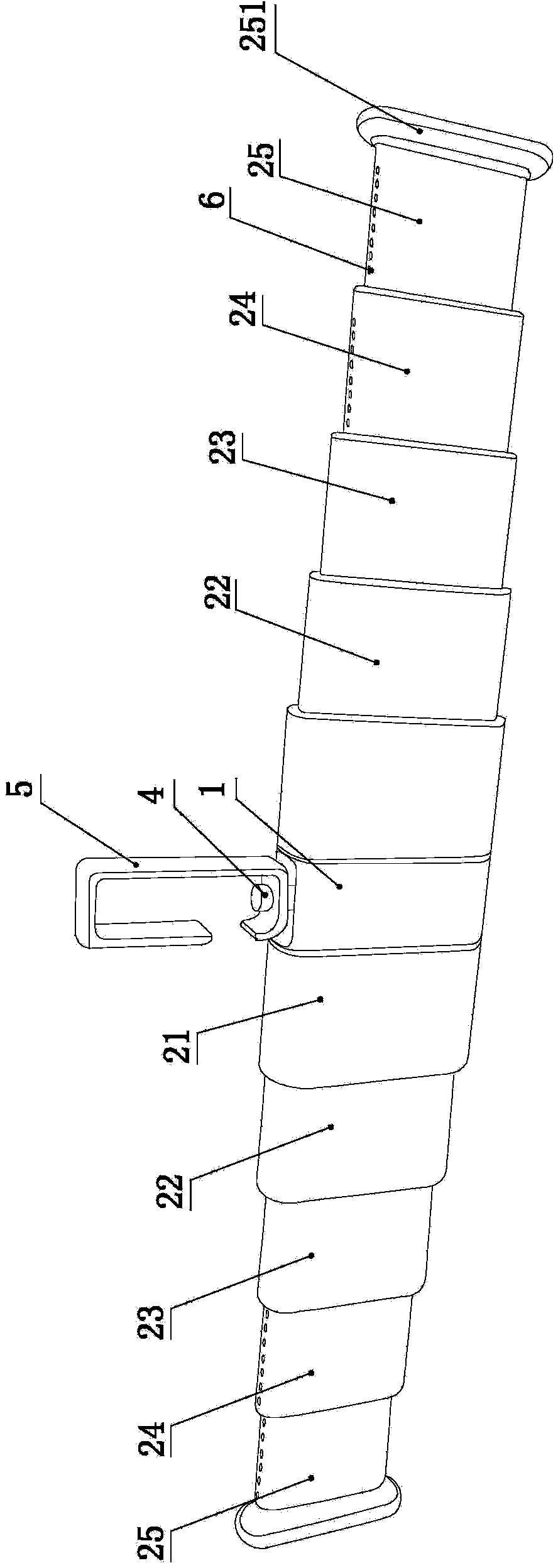

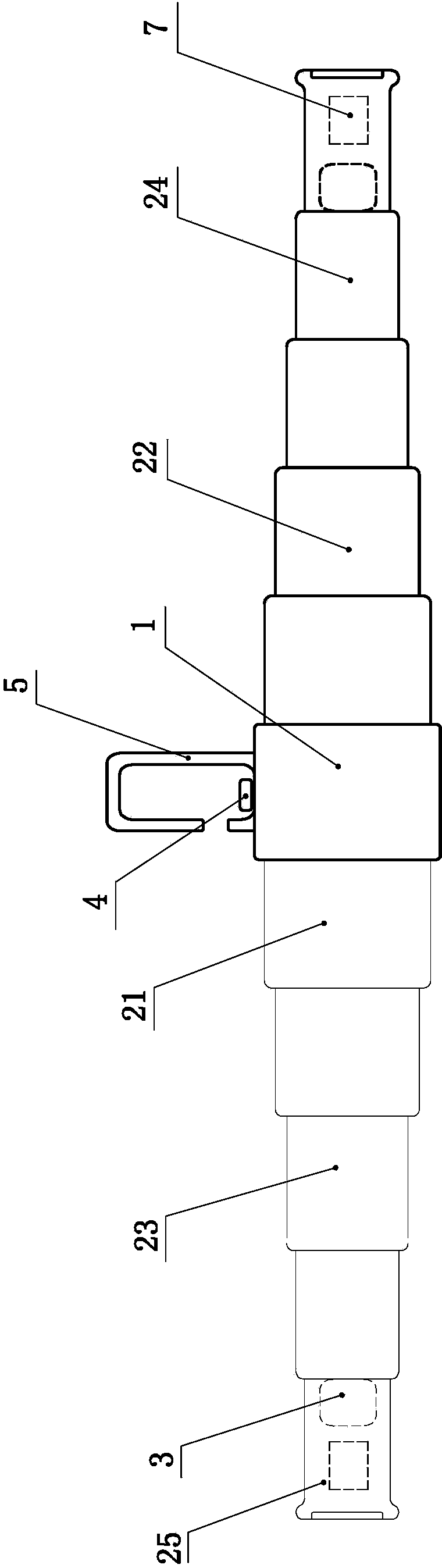

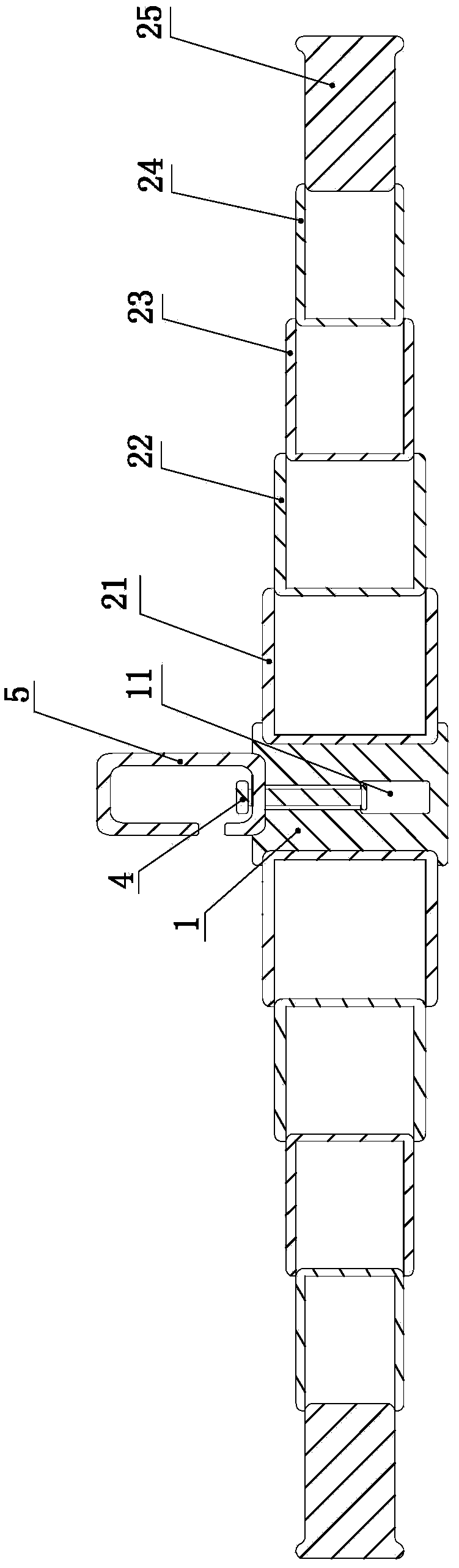

Telescopic hanger for airing socks

The invention discloses a telescopic hanger for airing socks, relates to the technical field of sock airing, and aims to solve the problem that socks are dried slowly in rainy days. The telescopic hanger is characterized in that a hook can be folded into a base, a fixed joint is disposed on each of two sides of the base, telescopic joints are disposed in the inner cavity of each fixed joint, a heater and a storage battery which are used for heating and drying the socks are disposed on the telescopic joint at the tail end. The telescopic hanger has the advantages that the telescopic joints can be pulled out during use, the telescopic joints can be put back into the fixed joints when the telescopic hanger is not needed, the size of the whole hanger is reduced after the hanger is folded, and storage is facilitated.

Owner:UNIV OF JINAN

Device and process for directly breaking shells of fresh walnuts with green peels

The invention discloses a device and a process for directly breaking shells of fresh walnuts with green peels. The device comprises a bottom plate, a switch, a cleaning tank, a drying tank, a cylinder, a pressing block, a turntable, a placing plate, a first motor, a second motor and a vibration motor, a screening plate is arranged and used for screening the dried fresh walnuts with the green peels, a vibration motor works to drive the screening plate to vibrate, therefore, the speed of fresh walnuts with green peels passing through screening holes is increased, and the screening efficiency isimproved. The screened walnuts are further taken out through discharging holes and flatly laid at the bottom of the inner side of a screening groove; the first motor rotates to drive the turntable torotate; therefore, the placing plate on which the walnuts are placed is moved to the position under the pressing block; the air cylinder is used for driving a piston rod to extend, so that the pressing block is pushed to move downwards to extrude and break shells of walnuts; and meanwhile, an operator can synchronously place the walnuts on other placing plate, continuous shell breaking of green-peel walnuts is achieved, the shell breaking efficiency is high, and the damage rate of walnut kernels is further obviously reduced.

Owner:XINJIANG UNIVERSITY

Solar energy humanoid clothes drying device

PendingCN109722868AFast dryingRealize heating and dryingOther drying apparatusTextiles and paperTemperature controlEngineering

The invention discloses a solar energy humanoid clothes drying device. The device comprises a drying part and a solar energy collecting part; the drying part comprises a clothes dryer and a fan; the fan is arranged on the lower portion of the clothes dryer; the solar energy collecting part comprises a solar energy header and a heat collector; the solar energy header is connected with the clothes dryer; the heat collector is connected with the solar energy header through a pipeline; the device comprises a water pump and a temperature control valve; an inlet of the water pump is connected to anoutlet of the solar energy header through the temperature control valve, an outlet of the water pump is connected to an inlet of the clothes dryer, and an outlet of the clothes dryer is connected to an inlet of the solar energy header. Accordingly, wet clothes are heated and dried, the drying speed of the clothes is increased, and energy is saved.

Owner:SHANGHAI MARITIME UNIVERSITY

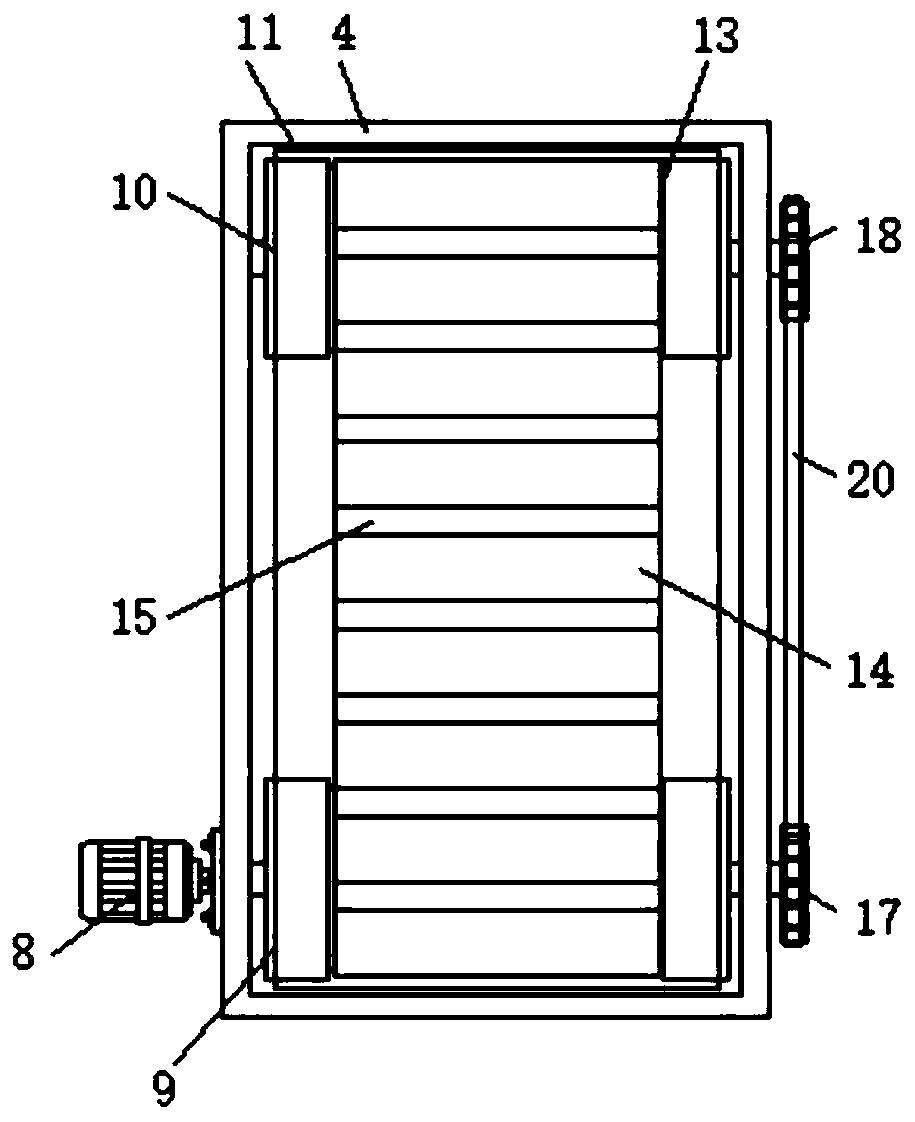

Electrothermal drying rolling wheel type textile drying box

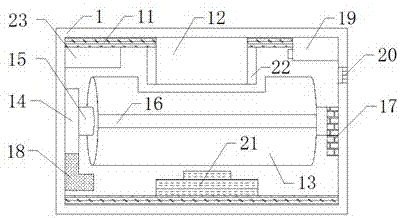

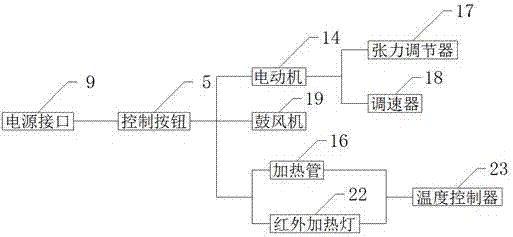

InactiveCN107543371ARealize heating and dryingAchieve rotationDrying solid materials without heatDrying gas arrangementsSurface mountingElectric motor

The invention discloses an electric drying roller type textile oven, which comprises a device body and a base. An observation window is cut on one side of the outer surface of the device body. A control button is installed directly below the observation window. The center of the upper surface of the device body A feed inlet is cut at the position, and a conveyor belt is installed at the center of the device body, and the conveyor belt communicates with the feed inlet. A motor is installed at the center of the inner wall of one side of the device body, and a rotating shaft, a roller is welded and fixed at the center of the outer surface of the rotating shaft, and a tension regulator is installed at the center of the inner wall on the other side of the device body, and the tension regulator is electrically connected to the motor through a wire. A power interface is installed at the center of the outer surface, and the power interface is electrically connected with the control button through a wire. The electric drying roller type textile oven has uniform heating and improves the drying efficiency of textiles.

Owner:SUZHOU XIUWEI TEXTILE FINISHING AUTOMATION CO LTD

Test tube cleaning equipment used in chemistry laboratory

InactiveCN110695035ASimple structureSimple and efficient operationHollow article cleaningHeating arrangementTest tubeWater storage tank

The invention discloses test tube cleaning equipment used in a chemistry laboratory. The test tube cleaning equipment comprises a base, a connecting column, a storage table and a water tank. The connecting column is fixedly mounted on the outer surface of the upper end of the base. The storage table is slidably mounted on the outer surface of the connecting column. The water tank is fixedly mounted on the outer surface of the upper end of the connecting column. A plurality of connecting rods are fixedly mounted on the edge of the outer surface of the lower end of the water tank at equal intervals. A cleaning head is fixedly mounted at one end of each connecting rod. According to the test tube cleaning equipment, test tubes with different sizes can be clamped and fixed so as to be cleaned subsequently, and more test tubes can be cleaned every time, so that the cleaning efficiency of the test tubes is improved, and the labor intensity of workers is relieved; and meanwhile, the cleaned test tubes can be heated and dried and can be simply sterilized by means of dissipated heat, so that the cleanliness and sanitation of the test tubes are comprehensively guaranteed.

Owner:汪家烨

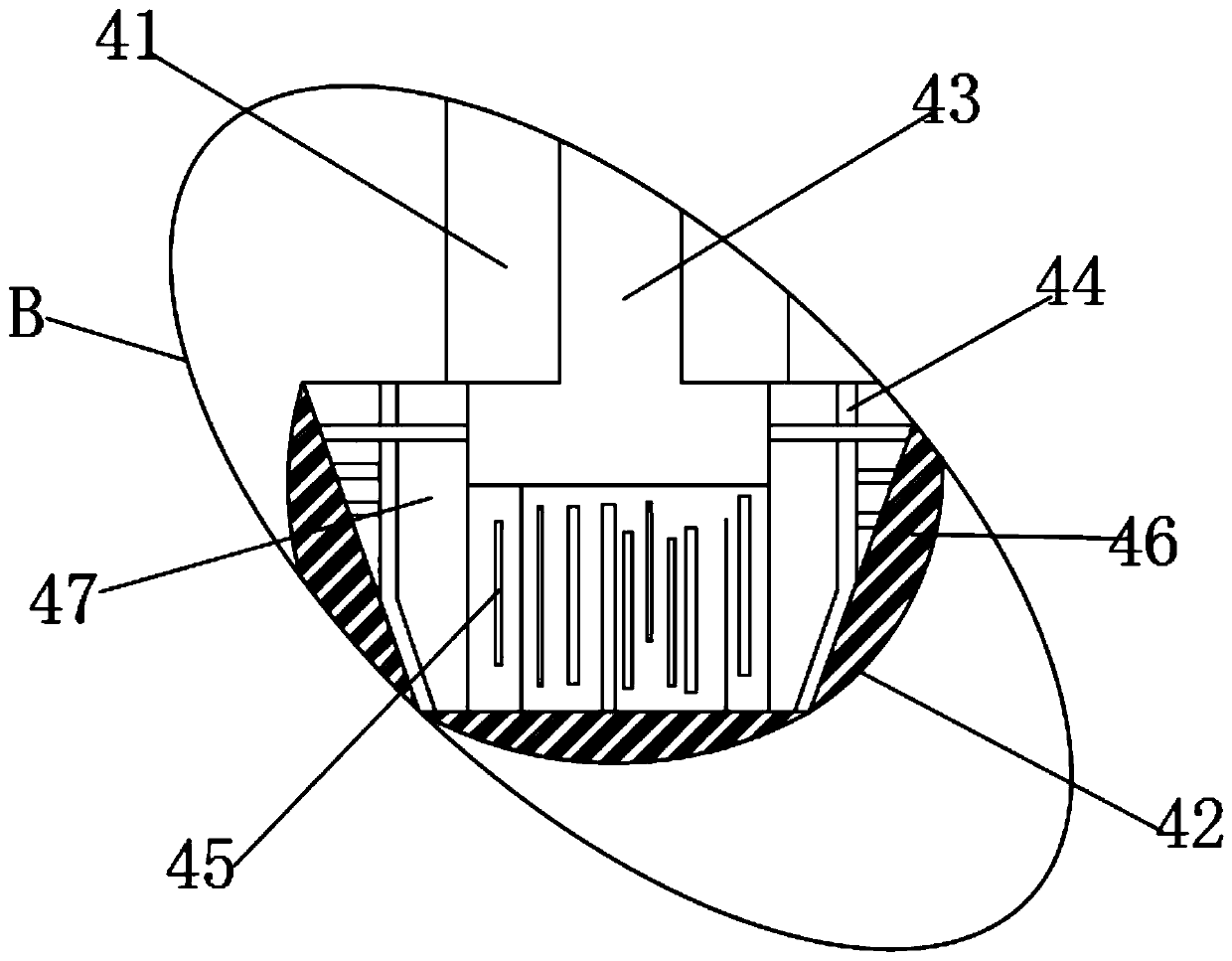

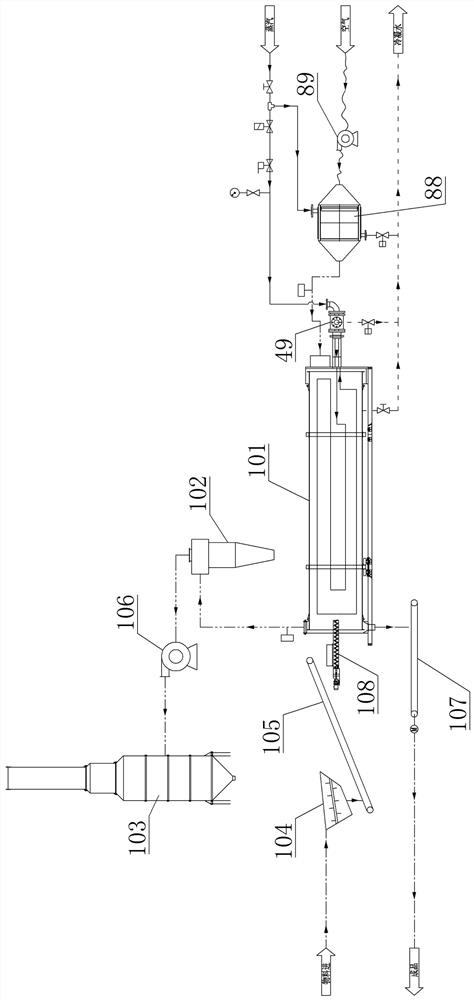

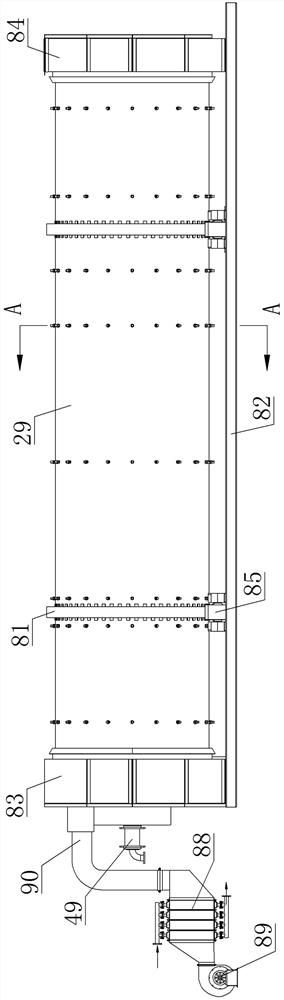

Drying system for silicon carbide powder

PendingCN110530142AReduce pollutionRealize heating and dryingDrying gas arrangementsDrying solid materialsInlet channelAir pollution

The invention relates to a drying system for silicon carbide powder and relates to the technical field of silicon carbide powder production. The drying system comprises a vertically arranged drying cylinder, a stirring chamber is arranged on the lower portion of the drying cylinder, a hot air inlet is formed in the side wall of the stirring chamber, the hot air inlet is connected with a tangentialair inlet channel, and the front end of the tangential air inlet channel is connected with a hot air mechanism for providing hot air for the drying cylinder. A stirrer is arranged in the stirring chamber, a powder ascending channel is arranged in the drying cylinder above the stirring chamber, a wet material feeding port is formed in the butt joint position between the powder ascending channel and the stirring chamber, the wet material feeding port is connected with a feeding mechanism, and a temperature measuring point is arranged on the powder ascending channel above the wet material feeding port. A dry material discharge port is formed in the upper part of the powder ascending channel and is connected with a powder separation system through a discharge pipeline; and an induced draft fan is arranged on a tail gas exhaust pipe of the powder separation system. The drying system has the characteristics that drying is uniform and thorough, material waste is reduced, cost is reduced, andair pollution is reduced.

Owner:连云港市沃鑫高新材料有限公司

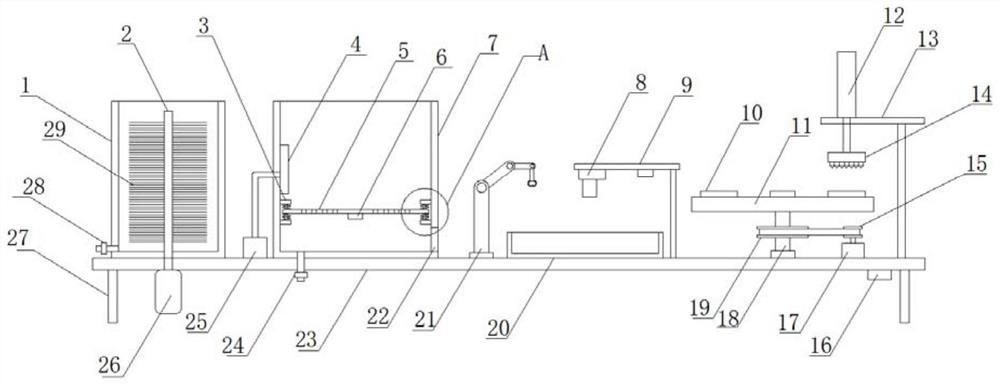

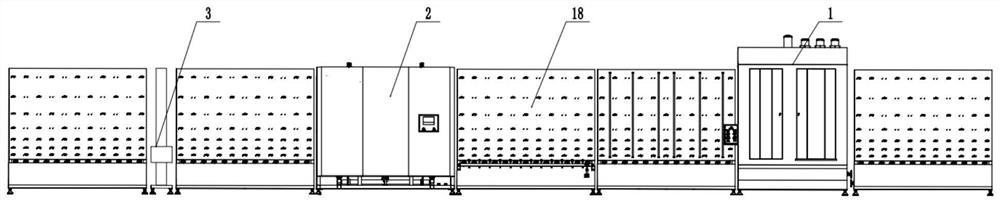

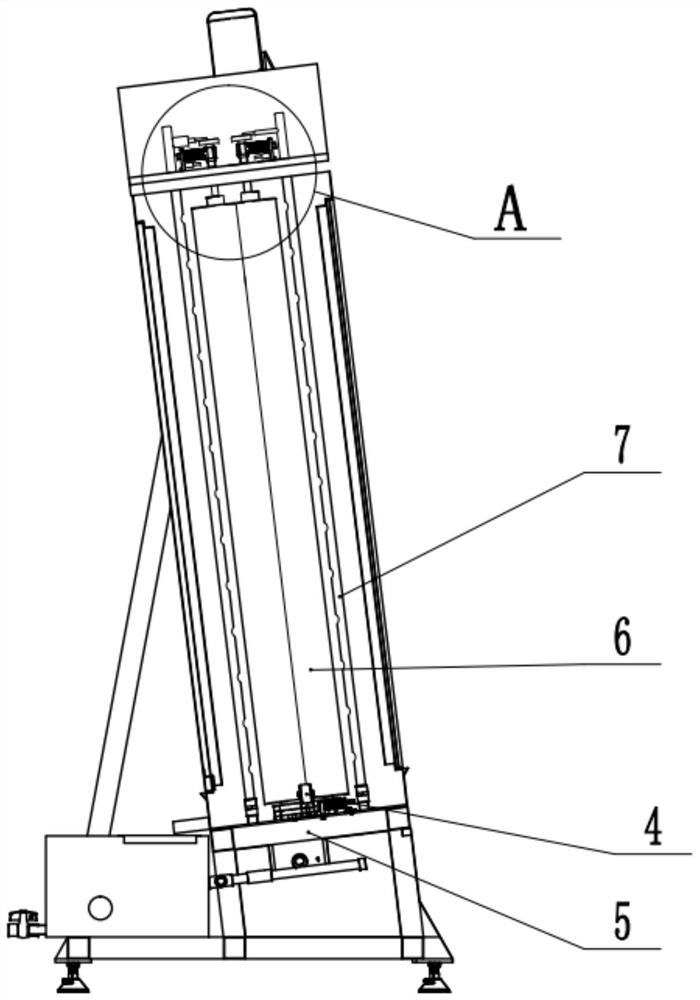

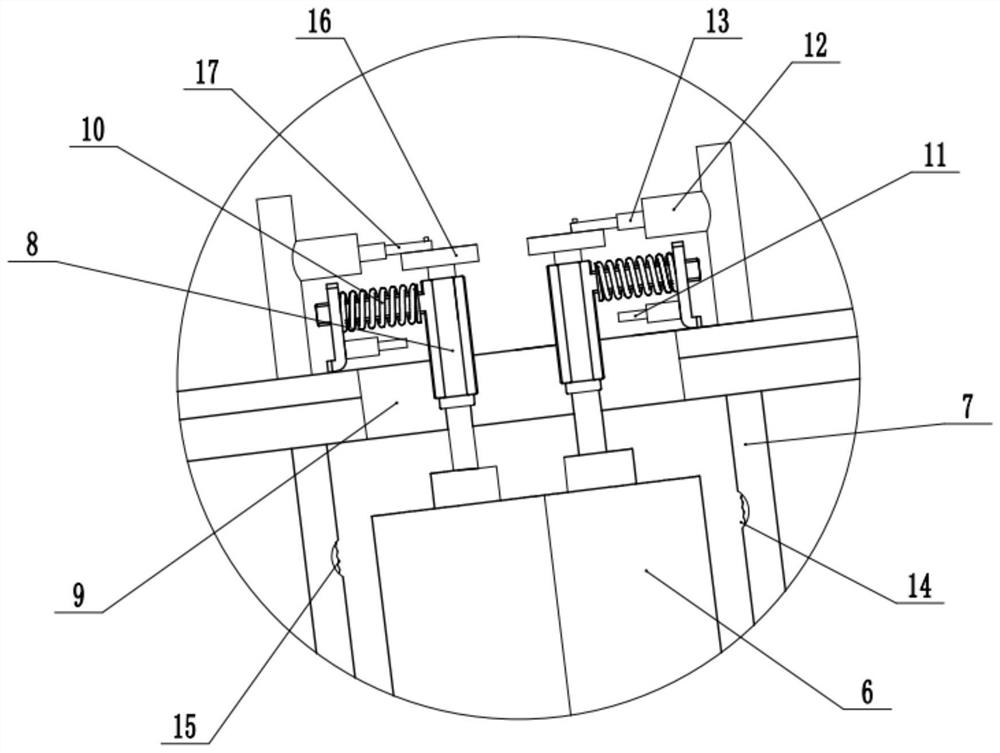

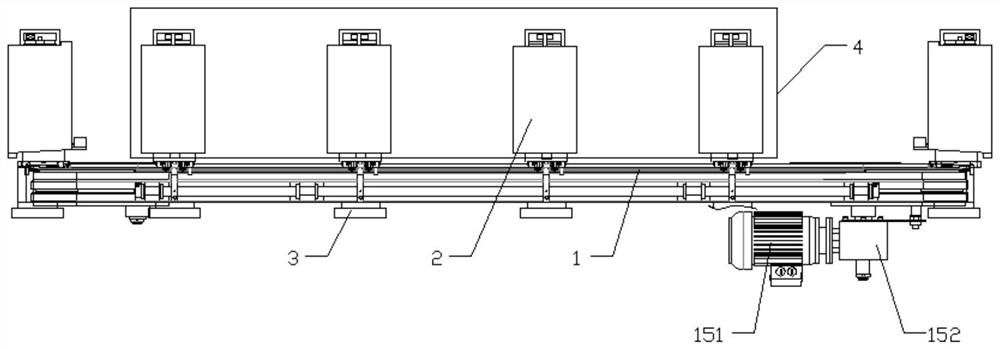

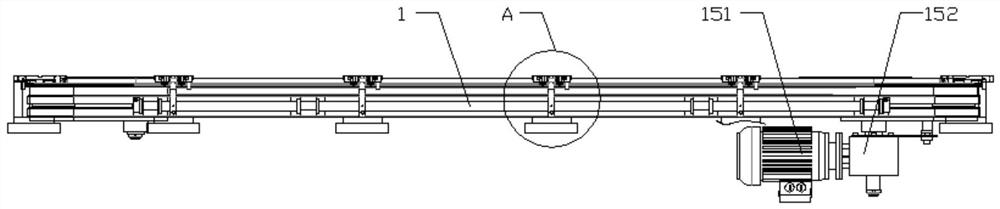

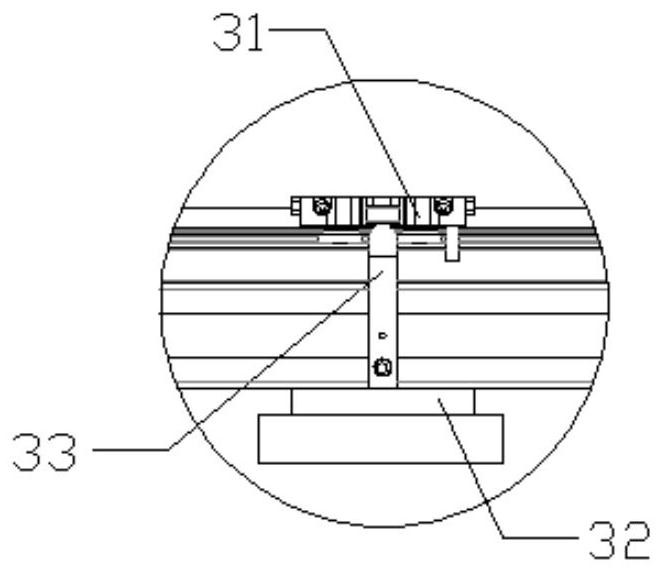

Hollow glass production line

InactiveCN112340458AImprove drying efficiencySpeed up water evaporationLiquid surface applicatorsCharge manipulationCrankPiston

The invention belongs to the technical field of glass manufacturing, and particularly discloses a hollow glass production line which comprises a supporting frame, wherein a spray washing mechanism anda drying mechanism are fixed to the supporting frame, the drying mechanism comprises a plurality of cleaning rollers and a plurality of exhaust pipelines, the cleaning rollers are coaxially and fixedly connected with a driving motor, the ends of the cleaning rollers are rotationally connected with sliding blocks, a slide way used for sliding connection of the sliding blocks is horizontally arranged on the rack, the exhaust pipelines are fixedly connected to the rack, the cleaning rollers are coaxially and fixedly connected with a crank, a connecting rod is hinged to the eccentric position ofeach crank, and a piston is hinged to the end, away from the corresponding crank, of each connecting rod and horizontally and slidably connected to one end of the corresponding exhaust pipeline in a sealed mode; and a plurality of air outlet holes are formed in the sides, close to the cleaning rollers, of the exhaust pipelines, and electric heating wires are fixedly connected in the exhaust pipelines. The invention aims to provide the hollow glass production line so as to solve the problem that the surface of glass is not thoroughly dried after being washed.

Owner:CHONGQING CONGBO ENERGY SAVING GLASS CO LTD

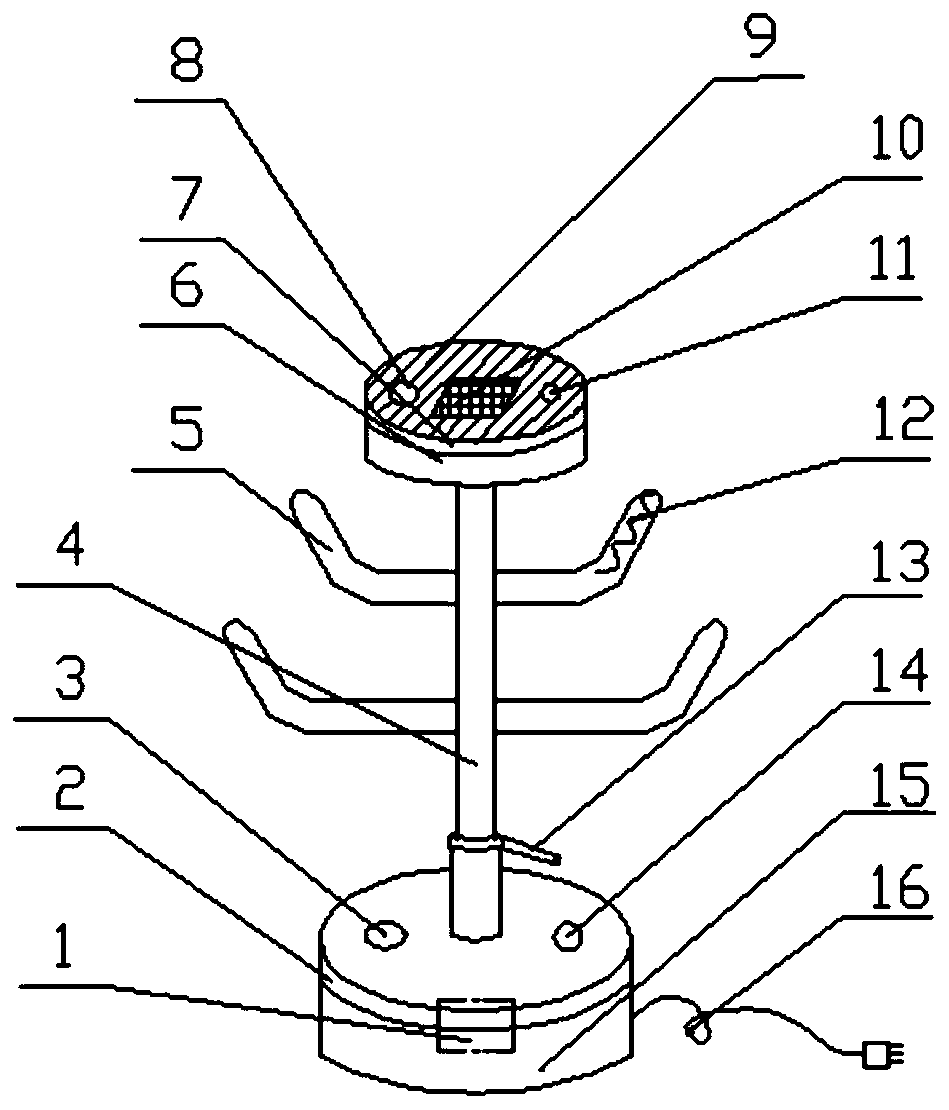

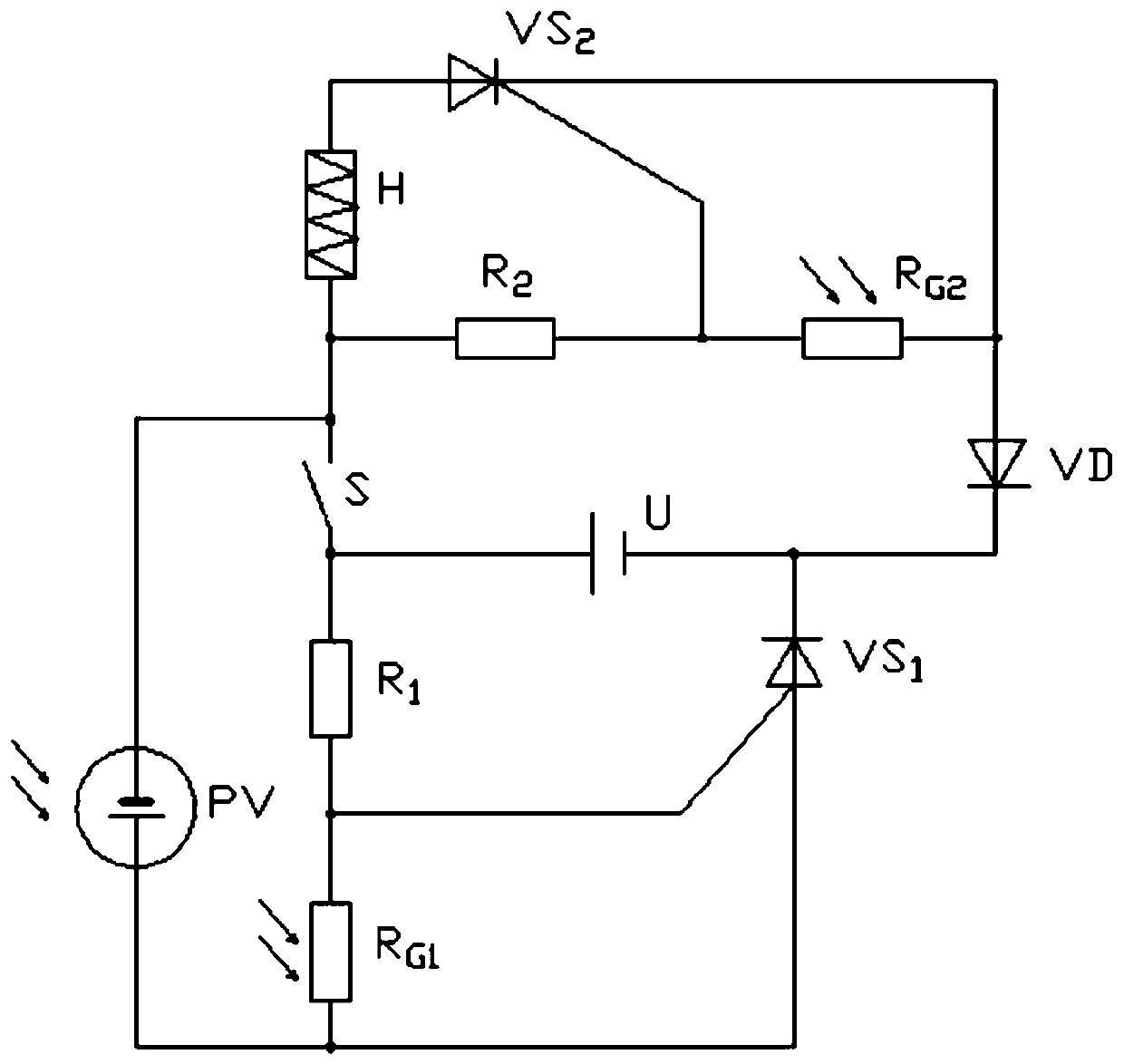

Self-adaptive photosensitive energy-saving shoe drying rack

InactiveCN110074637AUniform sunshineRealize heating and dryingApparel holdersFootwear cleanersSelf adaptiveEngineering

The invention relates to a self-adaptive photosensitive energy-saving shoe drying rack, which comprises a base, a main shaft and a circuit box in sequential arrangement from bottom to top, wherein a plurality of hanging racks are arranged on the main shaft; an electric motor and a first photoresistor are arranged inside the base; the electric motor is connected with the main shaft to make the mainshaft rotate; the first photoresistor is respectively connected with the electric motor and a power supply to form a rotating loop, and is used for controlling the on-off of the electric motor. Compared with the prior art, the self-adaptive photosensitive energy-saving shoe drying rack has the advantages that the structure is simple; the practicability is strong; the energy is saved; the environment is protected, and the like.

Owner:SHANGHAI UNIV OF ENG SCI

Pretreatment device for soil detection

PendingCN109100198AAchieve dryingEasy to usePreparing sample for investigationEngineeringMechanical engineering

The invention discloses a pretreatment device for soil detection, which comprises a drying and grinding device, a cleaning device and a conveying and screening device connected between the drying andgrinding device and the cleaning device, wherein the drying and grinding device can dry, grind and filter soil; the soil meeting a particle size condition drop into a collection box for collection; grinding balls and gravel are conveyed and screened into the cleaning device by the conveying and screening device for cleaning; and the use of the grinding balls next time is facilitated. The pretreatment device can perform pretreatment, such as drying, grinding and screening, on the soil before analysis; manual participation is reduced; the efficiency is greatly improved; and the labor cost is lowered.

Owner:江苏新锐环境监测有限公司

Automatic duck feed processing device

PendingCN112691600AFully automatedEasy to operateRotating receptacle mixersFeeding-stuffThermodynamicsAnimal science

The invention discloses an automatic duck feed processing device which comprises a swing mechanism, a plurality of mixing devices movably mounted on the swing mechanism and used for mixing feed, and a heating box arranged on the swing mechanism. Each mixing device comprises a heat conduction shell, a stirring device and a power mechanism; the stirring device can be rotatably mounted in the heat conduction shell; the power mechanism is mounted on the heat conduction shell and is used for driving the stirring device to rotate; a feeding device for conveying the treated materials to the discharge opening is mounted in the heat conduction shell and is positioned below the stirring device; the bottom of each mixing device is connected with a swing mechanism through an installation base, and the swing mechanisms can drive the mixing devices to conduct cyclic transmission along the swing mechanisms. Different devices can be arranged on the periphery of the swing mechanism according to needs, and operations such as step-by-step material adding are achieved; the device is uniform in material mixing, materials can be dried while being mixed, mildewing can be prevented, the storage period is prolonged, and economic losses are reduced.

Owner:徐州众汇福英杰饲料有限公司

Tea caddy with drying function

InactiveCN108357800AEvenly heatedPrevent moisture deteriorationSealingContainers for heating foodElectricityHeat conducting

The invention discloses a tea caddy with a drying function. The tea caddy comprises a tank body and a tank cover with a detachable upper end, wherein an electric heating plate is arranged on the bottom of the tank body; a circulating battery is arranged below the electric heating plate; a charging socket is arranged on the side surface of the tank body; the charging socket is electrically connected with a circulating battery; the circulating battery is electrically connected with the electric heating plate; a plurality of inner heat-conducting rods and outer heat-conducting rods, which are uniformly distributed along the center of the circle, are arranged on the electric heating plate; the outer heat-conducting rods are positioned at the peripheries of the inner heat-conducting rods; a plurality of outer heat-conducting plates are arranged on the outer heat-conducting rods at equal distance; a plurality of inner heat-conducting sheets are arranged on the inner heat-conducting rods at equal distance; the outer heat-conducting sheets and the inner heat-conducting sheets are alternatively distributed up and down; a tray is arranged above the electric heating plate; a heat insulating layer is arranged at the lower end of the tray; and a thermal-insulation layer is arranged on the inner wall of the tank body. The tea caddy is used for removing water adsorbed by tea leaves by heatingtea leaves on each part in the tank body, so that inner environments of the tea leaves are dried, and therefore, the tea leaves are prevented from being moisturized and deteriorated.

Owner:ANHUI YILIANG TANK IDUSTRY TECH CO LTD

Cable cleaning and oiling device

InactiveCN109550727AAchieve heatingRealize heating and dryingCleaning using toolsLiquid spraying apparatusFuel tankHydraulic pump

The invention discloses a cable cleaning and oiling device. A third mounting shaft is mounted on a base and provided with an oiling tank, a first hydraulic pump is arranged on the oiling tank, a firstwaste collecting tank is mounted on the third mounting shaft, and a first discharging pipe is arranged at the lower end of the first waste collecting tank; a fourth mounting shaft is mounted on the base and provided with a cleaning tank, a first conveying pipe is mounted at the lower end of the cleaning tank, and the cleaning tank communicates with a second waste collecting tank through the firstconveying pipe; the second waste collecting tank is mounted on the fourth mounting shaft, a second discharging pipe is arranged at the lower end of the second waste collecting tank, a second conveying pipe is mounted at the lower end of the oiling tank, and the oiling tank communicates with the first waste collecting tank through the second conveying pipe; the cleaning tank is used for cleaning acable, and the oiling tank is used for oiling the cable. The cable can be cleaned and subjected to oiling drying treatment in the cable coiling process, and thus cable coiling efficiency and qualityare greatly improved.

Owner:安徽牡东通讯光缆有限公司

A drying device for insulating paper processing

ActiveCN114046642BAchieve dryingRealize heating and dryingDrying solid materials without heatDrying gas arrangementsThermodynamicsDry structure

The invention provides a drying device for insulating paper processing, which relates to the technical field of insulating paper drying, including: a main frame, a first drying structure, an auxiliary part, a second drying part and a wind drying part; the main frame is placed on the ground , and the main body frame is rotatably connected with a paper guide roller, and the paper guide roller is transported with insulating paper. Because the roller is connected with the connecting pipe, the air intake pipe and the exhaust pipe in rotation, the two rollers are in a rotating state during the movement of the insulating paper. Simply put, if the contact between the roller and the insulating paper If the position does not change, the temperature at the position where the roller contacts the insulating paper will decrease, and after changing the contact position with the insulating paper through the rotation of the roller, it can ensure that the temperature of the roller and the insulating paper is balanced. The rotation of the impeller can achieve wind drying, and the cooperation between the impeller and the seat body can realize wind blocking and diversion, and the hot gas after diversion can be more in contact with the paper.

Owner:江苏玫源新材料有限公司

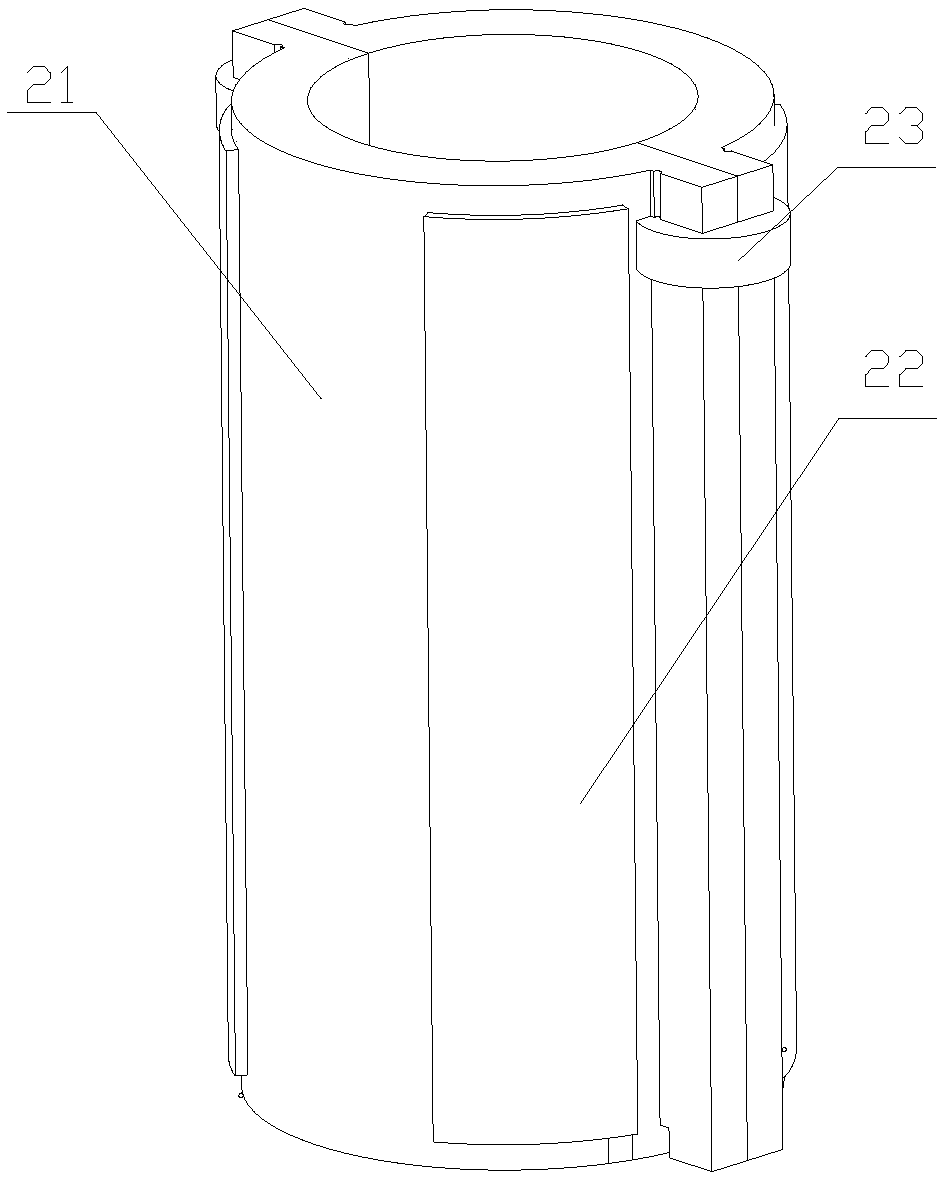

Recycled plastic drying device

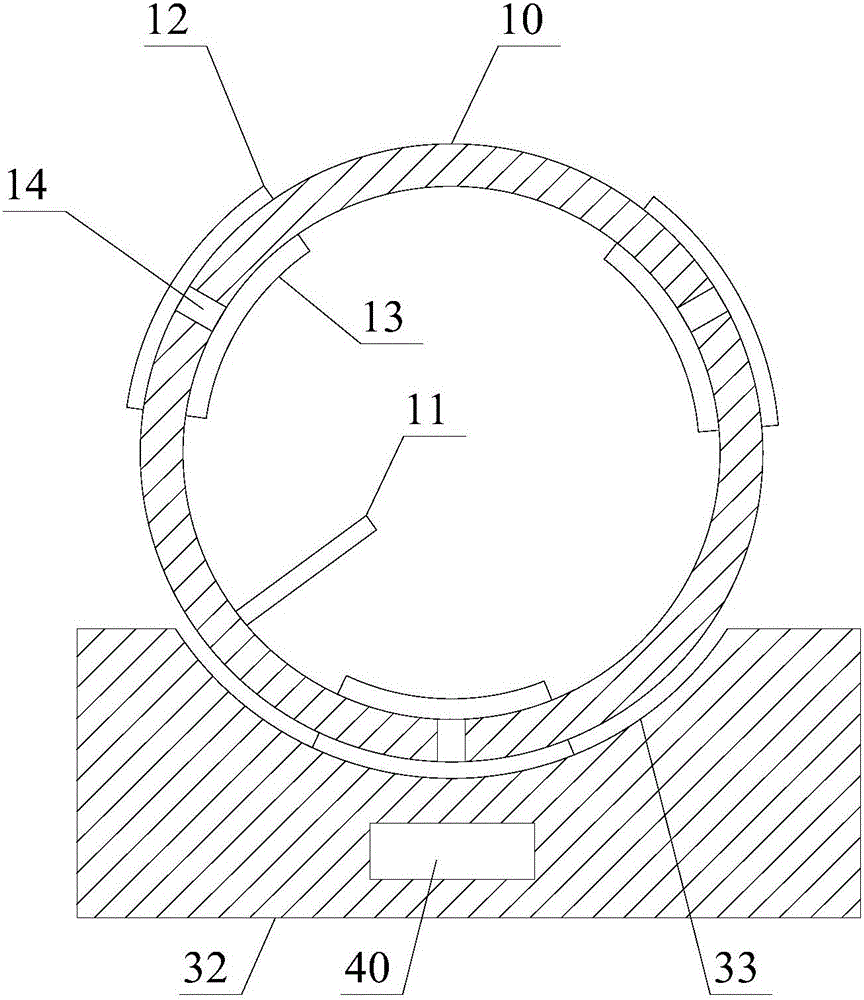

InactiveCN106482474AImprove mixing efficiencyWell mixedDrying chambers/containersDrying machines with non-progressive movementsHeat conductingDrive motor

The invention discloses a recycled plastic drying device. A drying box of the recycled plastic drying device adopts a hollow cylindrical structure; a driving motor is connected with the center of one end of the drying box; a material port is formed in the opposite other end of the drying box; long strip-shaped ventilating holes are densely formed in the outer circumferential surface of the drying box; outer heat-conducting fins are arc-shaped, and the outer heat-conducting fins are fixed to the outer circumferential surface of the drying box; inner heat-conducting fins are arc-shaped, and the inner heat-conducting fins are fixed to the inner circumferential surface of the drying box; the inner heat-conducting fins correspond to the outer heat-conducting fins one by one; the inner heat-conducting fins are connected with the outer heat-conducting fins through heat-conducting columns running through the circumferential wall of the drying box; the driving motor is supported on a motor supporting component; a drying box supporting component is provided with an arc-shaped groove matched with the outer circumferential surface of the drying box; the drying box is placed inside the arc-shaped groove; an electric heater is arranged inside the drying box supporting component. The recycled plastic drying device is high in drying efficiency and good in safety.

Owner:重庆明杰塑胶有限公司

Incandescent lamp fitting for fishery farm

InactiveCN108224237AReduce humidityReduce short circuitLighting support devicesLighting heating/cooling arrangementsBiochemical engineeringAluminum foil

The invention discloses an incandescent lamp fitting for a fishery farm. The incandescent lamp fitting comprises a lamp shade; a lamp cap is arranged at the top end of the lamp shade; a second fixingblock is arranged on one side of the lamp shade; one side of the second fixing block is rotationally connected with a rotating shaft; a ratchet wheel is arranged at one end of the rotating shaft; oneside of the rotating shaft is connected with a second fixing plate; one side of the second fixing plate is rotationally connected with a pawl; the pawl is clamped with the ratchet wheel; a second fixing ring is arranged at one end of the second fixing plate; a fixed bolt penetrates through the interior of the second fixing ring; the fixed bolt penetrates through a first fixing ring; the first fixing ring is welded on one side of a first fixing plate; the rotating shaft is rotationally connected with a first fixing block; the first fixing block is arranged on one side of the lamp shade; a shutter is arranged at the top of the lamp shade; and aluminum foil fins are arranged on the lower surface of the shutter. By taking an incandescent lamp as a light source and matching with the aluminum foil fins, ambient air of the incandescent lamp fitting is heated and dried, and the probability of short circuited failures of the incandescent lamp fitting is reduced.

Owner:葛成燕

A kind of metal graphene composite material and its preparation method and preparation device

ActiveCN109161715BIncrease productivityImprove electrode performanceGrapheneChemical vapor deposition coatingChemical platingCopper foil

The invention discloses a metal graphene composite as well as a preparation method and device thereof. The composite is prepared from the following raw materials: copper foil, dilute hydrochloric acid, hydrogen, methane, PMMA, a FeCl3 solution, deionized water, carbon aerogel, a metal-containing chemical plating solution, acetone and inert gas. The preparation method comprises the following steps:preparing nano porous metal, fishing out graphene from deionized water by using the nano porous metal, and placing the graphene into a drying oven for heating to obtain the metal graphene composite.According to comparison between graphene with metal support and graphene without metal support by experiments, metal graphene prepared with the preparation method of the metal graphene composite has the advantages that graphene with metal support has obviously improved specific capacity and better electrochemical performance, and has better effect as an electrode of a supercapacitor.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Double-cylinder type steam drying system

PendingCN113654318AEasy to installGuaranteed stabilityDrying gas arrangementsDrying chambers/containersThermodynamicsEngineering

The invention relates to a double-cylinder type steam drying system. The system comprises a double-cylinder steam drying machine and a steam heat exchange air distribution device for providing hot air into the double-cylinder steam drying machine, wherein an inner cylinder body and an outer cylinder body of the double-cylinder steam drying machine are cylindrical and are coaxially fixed; heat dissipation pipes are arranged on the inner surface and the outer surface of the inner cylinder body; heat dissipation pipes are also arranged on the inner surface of the outer cylinder body; a rotating connector is arranged at the end of a multi-stage cylinder body group; and the rotating connector is used for feeding air and returning water; air inlet pipe groups for introducing steam and water returning pipe groups for discharging condensate water are arranged between the rotating connector and the heat dissipation pipes. According to the double-cylinder type steam drying system, flexible guide pipes are arranged on the air inlet pipe groups, the water returning pipe groups and the air guide pipe groups; the precision requirements for machining and assembling are low, so that installation is convenient and fast; the flexible guide pipes can compensate uncontrollable variable stress; all pipelines and corresponding parts are protected; the fault rate is reduced; the maintenance cost is reduced; the working efficiency is improved; and continuous production of factories is facilitated.

Owner:JIAOZUO ZHENJIENNEG DRYING EQUIP DEV

DMDO crystal decolorizing and drying device

ActiveCN112742106AFast integrationImprove solubilityRotating receptacle mixersOrganic chemistryPhysicsCold air

The invention particularly relates to a DMDO crystal decolorizing and drying device which comprises a box body and glassware, a controller is arranged on the box body, the interior of the box body is divided into a crystallization area and a drying area, a decolorizing mechanism is arranged on the left side of the top of the box body, a suction filtration mechanism is arranged on the right side of the upper portion of the box body, a cooling mechanism is arranged in the crystallization area, and a drying mechanism is arranged in the drying area. DMDO crystals containing impurities can be decolored and dried, and the detachable stirring barrel is arranged so that the barrel can be conveniently cleaned after being used; the working mode that the stirring fan blades and the stirring barrel rotate at the same time is arranged so that DMDO crystals and petroleum ether can be rapidly mixed and stirred; liquid in the glassware can be quickly cooled in a cold air and water cooling double-cooling manner so that DMDO crystals can be quickly separated out.

Owner:HENAN INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com