Metal graphene composite as well as preparation method and device thereof

A composite material and metal graphite technology, which is applied in metal material coating technology, graphene, gaseous chemical plating, etc., can solve the problems of poor electrochemical performance, low specific capacity of graphene, and poor effect, and achieve an increase in specific capacity , good effect, good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

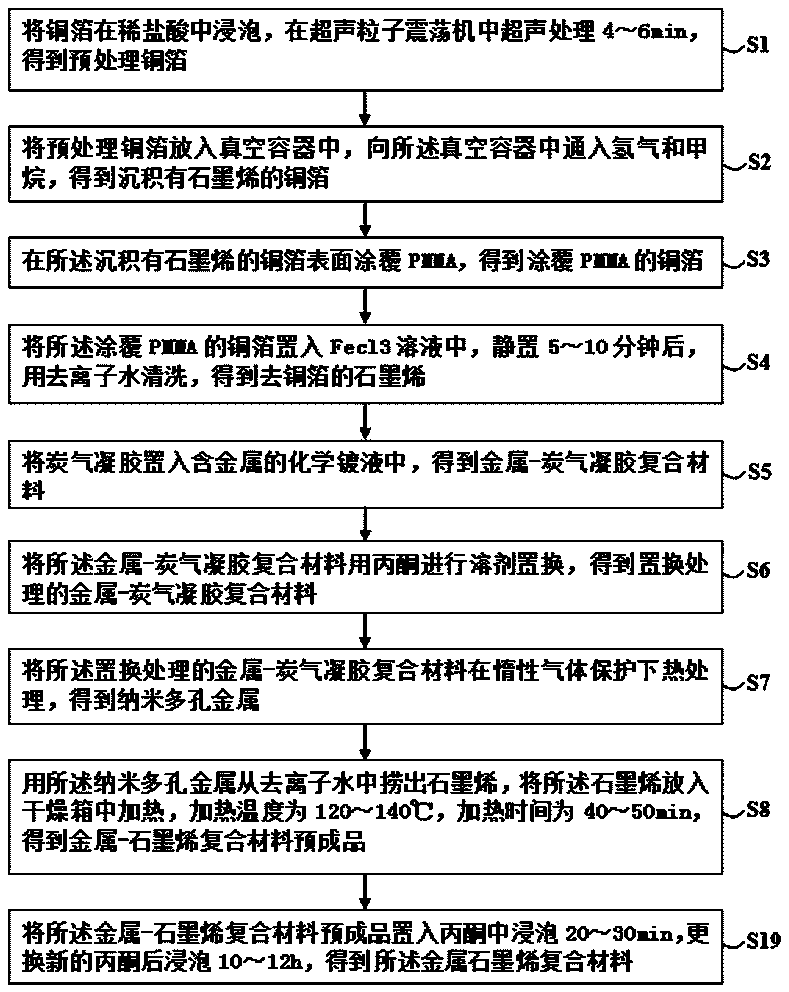

[0035] figure 1 It is a schematic flow chart of the preparation method of the metal graphene composite material provided in the first embodiment, including the following steps:

[0036] In step S1, the copper foil is immersed in dilute hydrochloric acid, and ultrasonically processed in an ultrasonic particle shaker for 4-6 minutes to obtain a pretreated copper foil.

[0037] In step S2, the pretreated copper foil is put into a vacuum container, and hydrogen and methane are passed into the vacuum container to obtain a copper foil deposited with graphene.

[0038] In step S3, PMMA is coated on the surface of the copper foil deposited with graphene to obtain PMMA-coated copper foil.

[0039] In step S4, the PMMA-coated copper foil is placed in Fecl 3 After standing for 5-10 minutes in the solution, wash with deionized water to obtain graphene without copper foil.

[0040] In step S5, the carbon aerogel is placed in a metal-containing electroless plating solution to obtain a metal-carbon ae...

Embodiment 2

[0048] Including the following steps:

[0049] In step S1, the copper foil is immersed in dilute hydrochloric acid, and ultrasonically processed in an ultrasonic particle shaker for 4-6 minutes to obtain a pretreated copper foil.

[0050] In step S2, the pretreated copper foil is put into a vacuum container, and hydrogen and methane are passed into the vacuum container to obtain a copper foil deposited with graphene.

[0051] Wherein, the hydrogen and methane are fed into the vacuum container, and the ratio of hydrogen to methane is 15:25.

[0052] In step S3, PMMA is coated on the surface of the copper foil deposited with graphene to obtain PMMA-coated copper foil.

[0053] In step S4, the PMMA-coated copper foil is placed in Fecl 3 After standing for 5-10 minutes in the solution, wash with deionized water to obtain graphene without copper foil.

[0054] In step S5, the carbon aerogel is placed in a metal-containing electroless plating solution to obtain a metal-carbon aerogel composite...

Embodiment 3

[0061] Including the following steps:

[0062] In step S1, the copper foil is immersed in dilute hydrochloric acid, and ultrasonically processed in an ultrasonic particle shaker for 4-6 minutes to obtain a pretreated copper foil.

[0063] In step S2, the pretreated copper foil is put into a vacuum container, and hydrogen and methane are passed into the vacuum container to obtain a copper foil deposited with graphene.

[0064] In step S3, PMMA is coated on the surface of the copper foil deposited with graphene to obtain PMMA-coated copper foil.

[0065] In step S4, the PMMA-coated copper foil is placed in Fecl 3 After standing for 5-10 minutes in the solution, wash with deionized water to obtain graphene without copper foil.

[0066] In step S5, the carbon aerogel is placed in a metal-containing electroless plating solution to obtain a metal-carbon aerogel composite material.

[0067] In step S6, the metal-carbon aerogel composite material is solvent replaced with acetone to obtain a meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com