Negative-pressure pulse cooperated ordinary pressure radio-frequency spouted-bed drying device and application thereof

A technology of atmospheric pressure radio frequency and drying equipment, applied in the direction of drying gas arrangement, heating equipment, drying of granular materials, etc., can solve the problems of no papers and patents retrieved, reduce energy consumption, shorten drying time, and realize circulation and recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

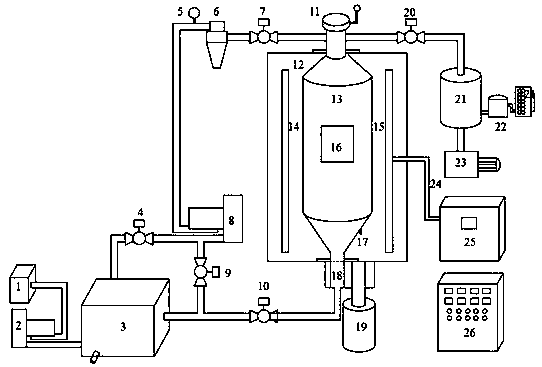

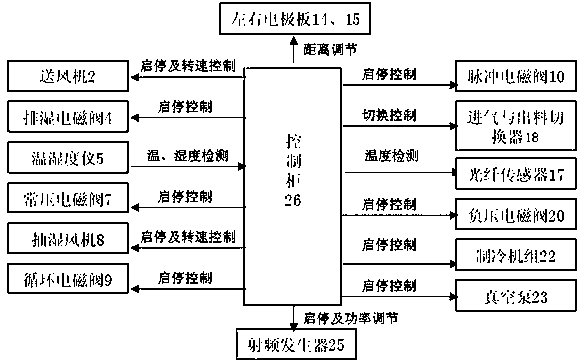

[0040] Such as figure 1 As shown, a negative pressure pulse combined with normal pressure radio frequency spouted bed drying device, including: air filter 1, blower 2, heat exchanger 3, dehumidification solenoid valve 4, temperature and humidity instrument 5, gas-solid separator 6 , normal pressure solenoid valve 7, dehumidifying fan 8, circulation solenoid valve 9, pulse solenoid valve 10, feed valve 11, radio frequency heating chamber 12, spouted bed 13, left electrode plate 14, right electrode plate 15, observation window 16 , fiber optic sensor 17, intake and discharge switch 18, product collector 19, negative pressure solenoid valve 20, cooler 21, refrigeration unit 22, vacuum pump 23, radio frequency conveying line 24, radio frequency generator 25 and control cabinet 26, etc. constituted.

[0041] The air filter 1 is a device for removing impurities in the air entering the spouted bed 13, the air blower 2 delivers the purified air to the heat exchanger 3, and the heat e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com