Pet feed drying device

A drying device, pet feed technology, applied in the direction of granular material drying, drying, drying machine, etc., can solve the problems of low drying efficiency, no screening function, etc., to improve production quality and improve drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

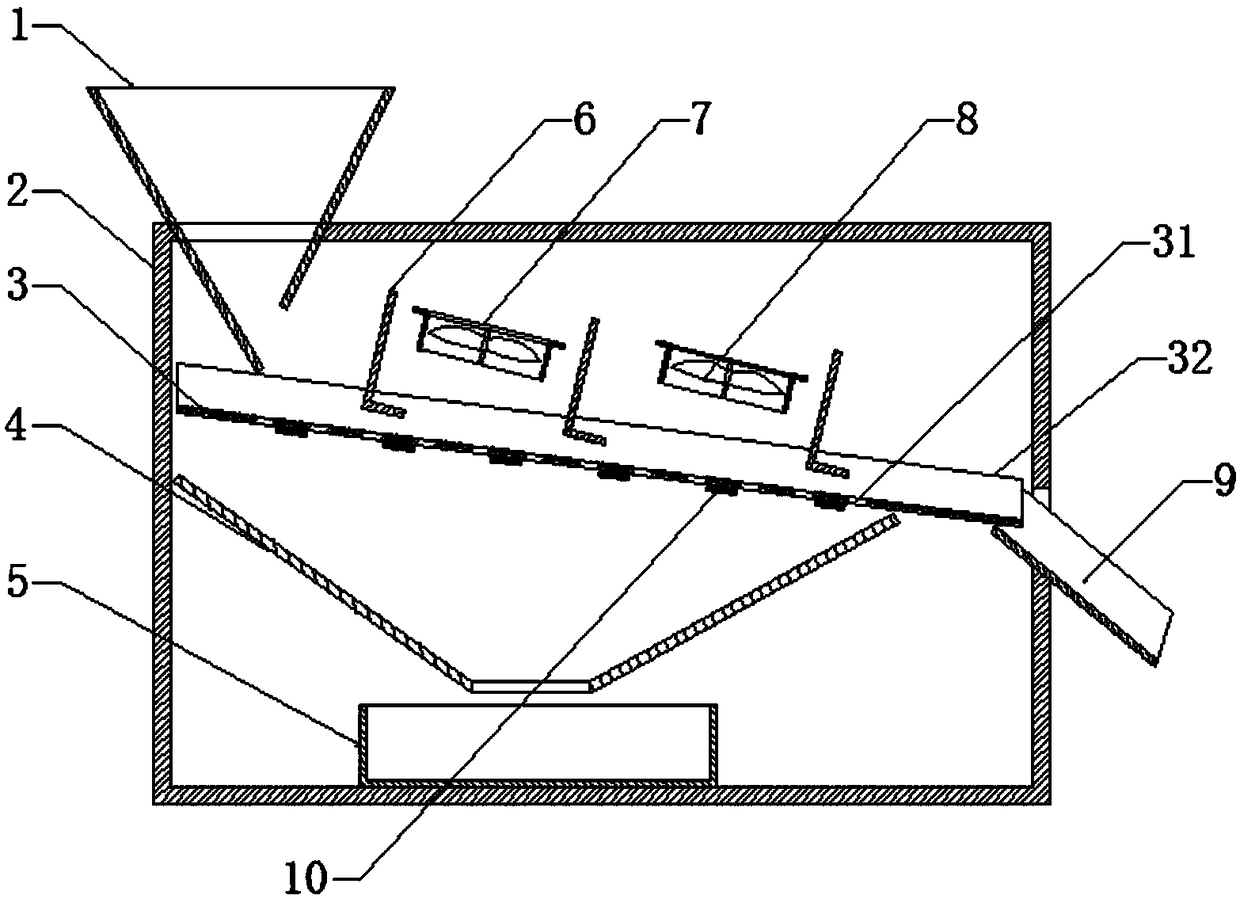

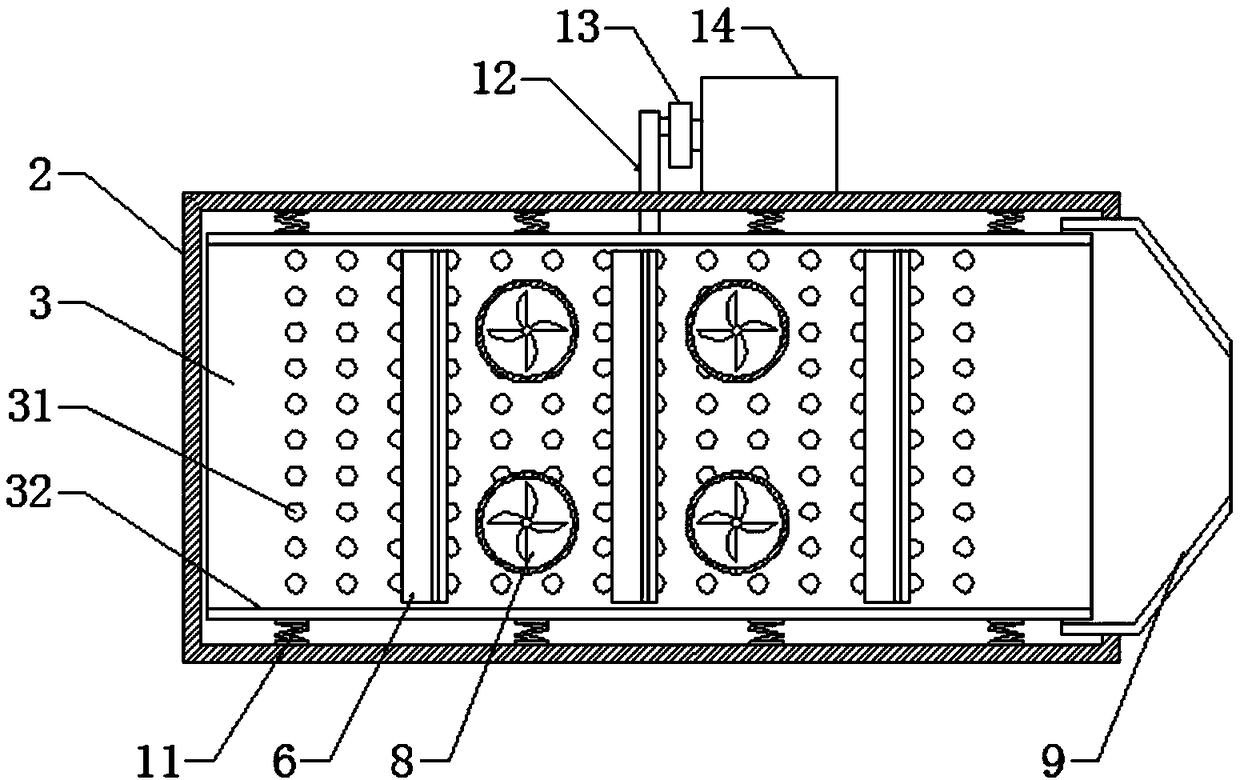

[0028] Embodiment 1, with reference to figure 1 , figure 2 , image 3 with Figure 4As shown, a pet feed drying device includes a hopper 1, a box body 2, a heating plate 3, a fan 8 and an electric heating sheet 10, and a hopper 1 is provided on the upper surface of the box body 2 near the left end for drying and feeding. And the inner side of box body 2 is provided with heating plate 3 transversely, and heating plate 3 is inclined to the lower right corner and is arranged to make spherical pellet feed roll to the lower right corner, and heating plate 3 lower surface is uniformly provided with several electric heating plates 10, through electric heating plate 10 heating the heating plate 3 to realize the drying of the spherical pellet feed, the surface of the heating plate 3 is uniformly provided with dense sieve holes 31 to realize the screening of the spherical pellet feed, and the front and rear edges of the upper surface of the heating plate 3 are provided with vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com