A drying device for insulating paper processing

A technology of drying device and insulating paper, which is applied in the direction of drying gas arrangement, drying solid materials without heating, progressive dryer, etc., can solve the problems of inability to combine, insufficient drying effect of insulating paper, affecting insulating effect, etc., and achieve enhanced friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Example: Please refer to Figure 1 to Figure 10 :

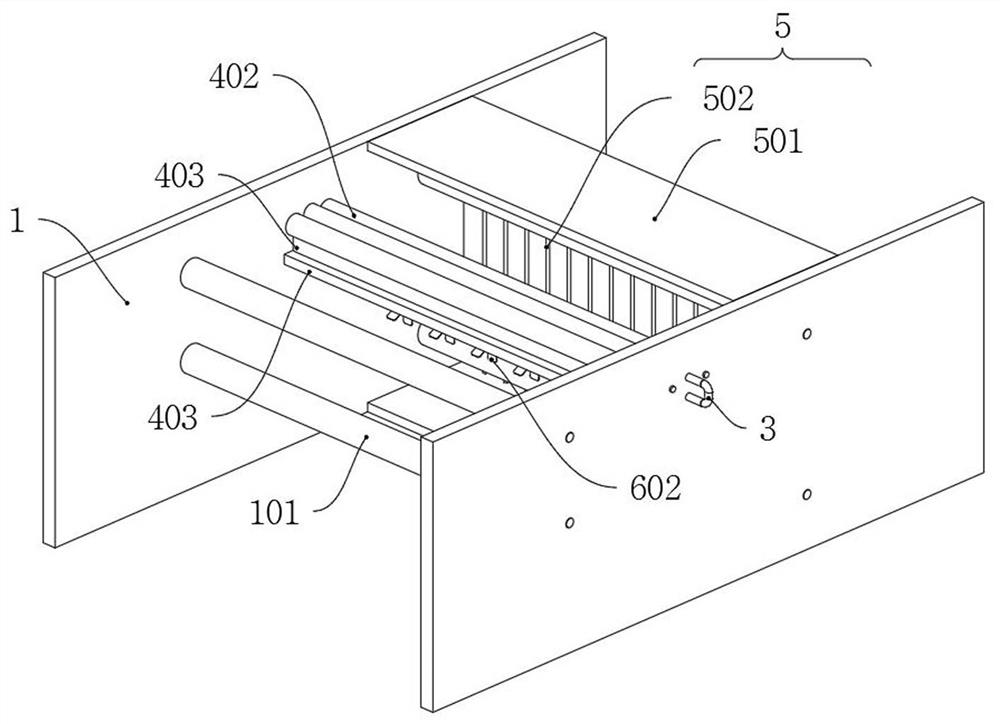

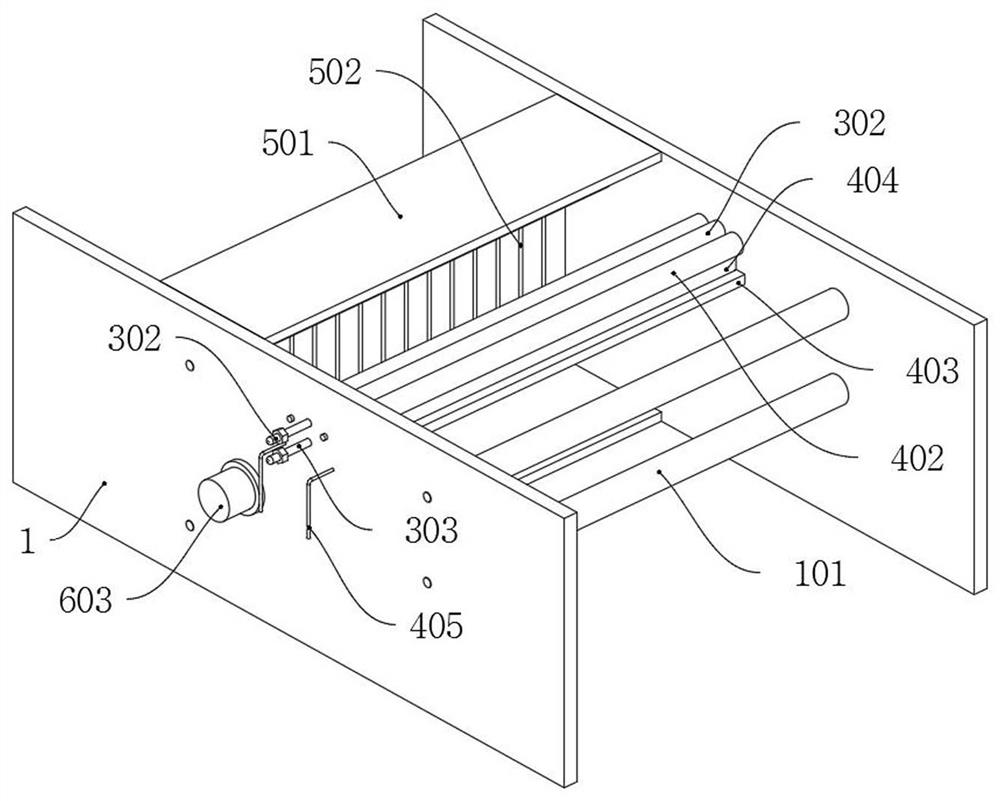

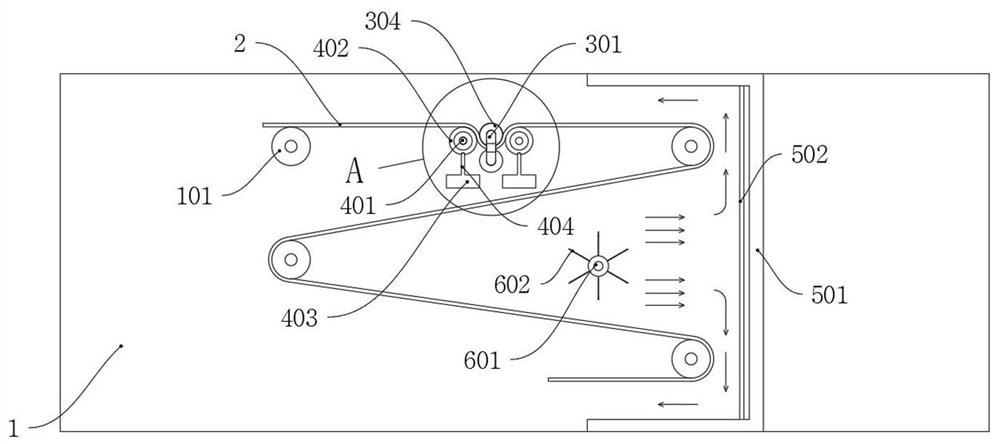

[0046] The present invention proposes a drying device for insulating paper processing, including: a main frame 1, a first drying structure 3, an auxiliary part 4, a second drying part 5 and a wind drying part 6;

[0047] The main body frame 1 is placed on the ground, and the main body frame 1 is rotatably connected with a paper guide roller 101, and the paper guide roller 101 is transported with insulating paper 2; the main body frame 1 is rotatably connected with a winding roller;

[0048] The first drying structure 3 is composed of a connecting pipe 301, an air intake pipe 302, an exhaust pipe 303 and a roller 304, and the connecting pipe 301 is installed on the main frame 1, and the connecting pipe 301 is a concave tubular structure;

[0049] The auxiliary part 4 is composed of a roller 401, a water-absorbing sleeve 402, a box body 403, an auxiliary plate 404 and a drain pipe 405, and there are two rollers 401, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com