Drying system for silicon carbide powder

A technology of silicon carbide powder and drying system, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of wet silicon carbide powder, poor drying quality, uneven drying, etc., and reduce material waste , Good drying quality, and the effect of reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

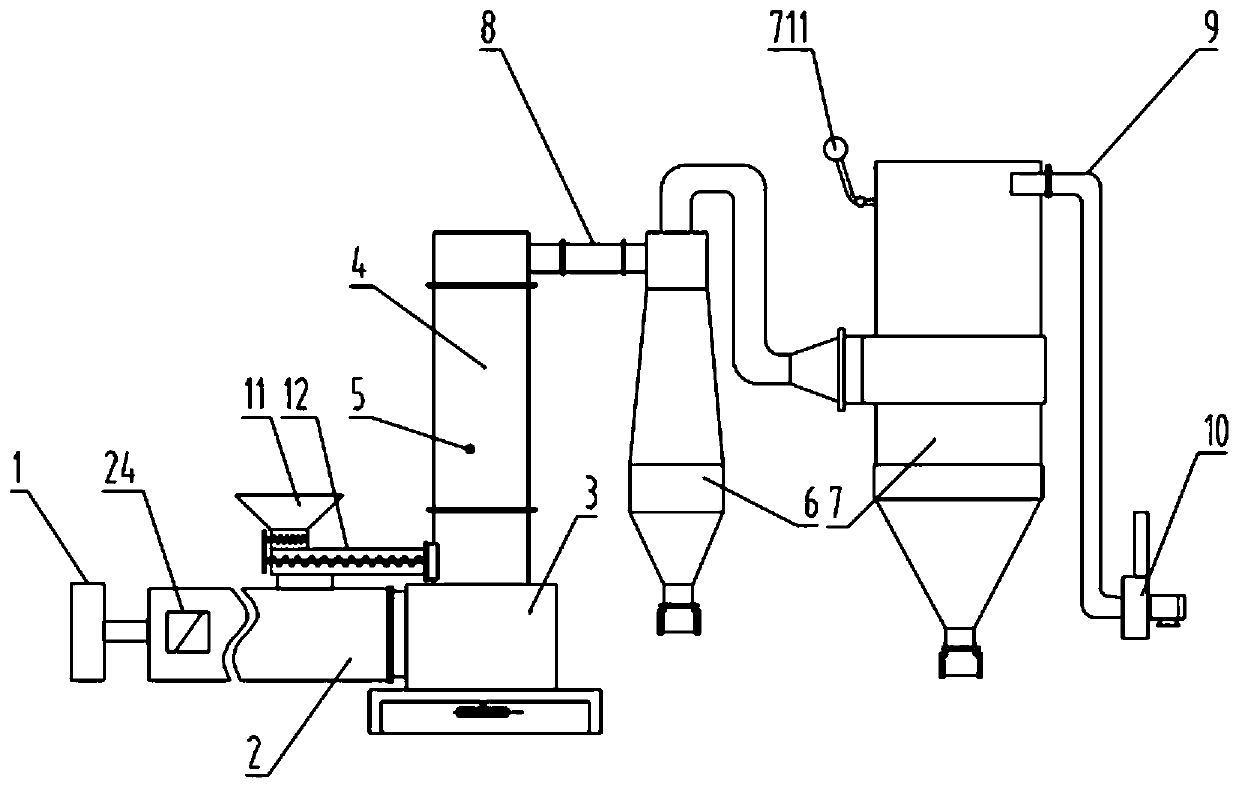

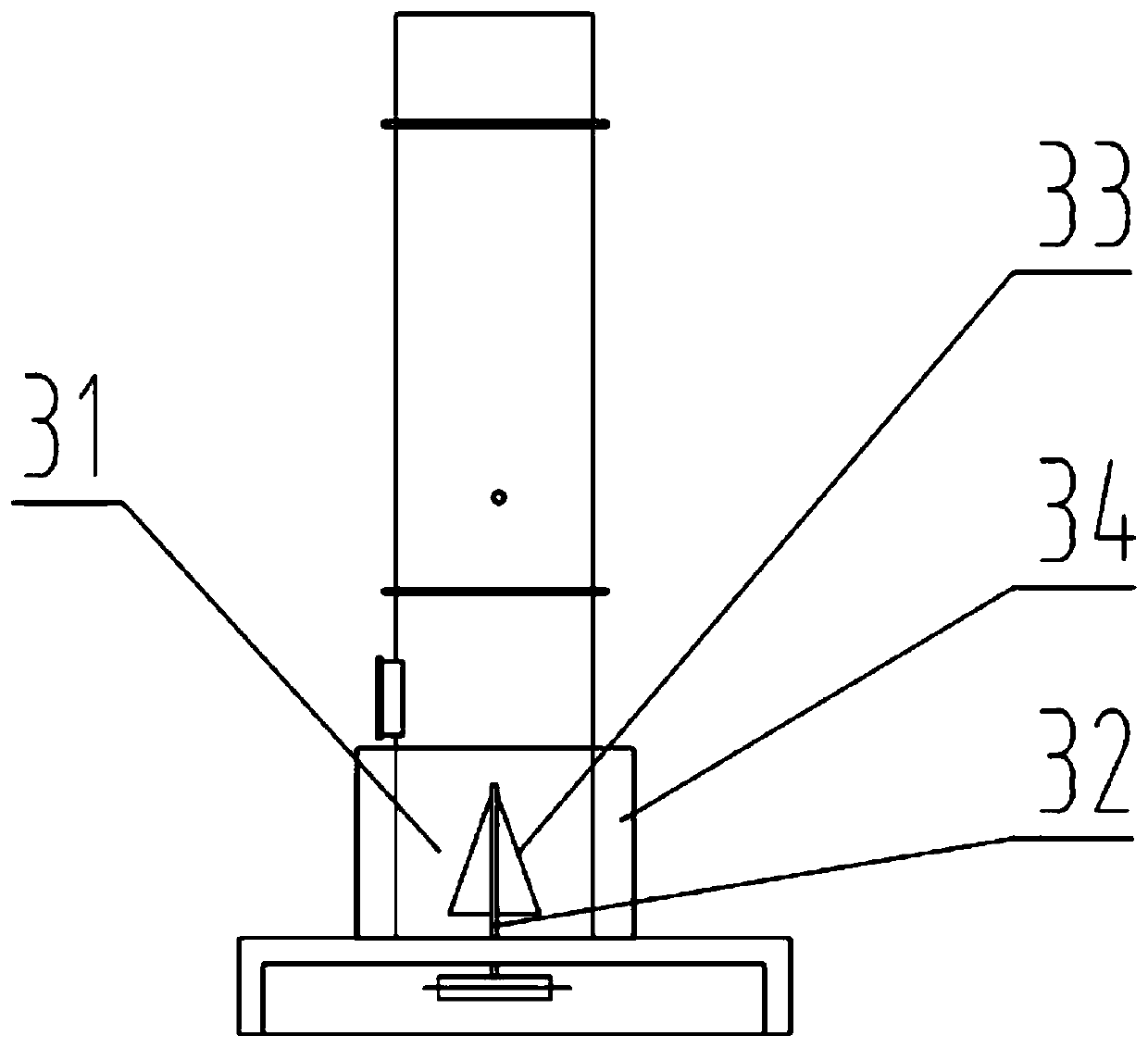

[0030] refer to figure 1 , a drying system for silicon carbide powder, comprising a vertically arranged drying cylinder 3, a mixing chamber 31 is provided at the bottom of the drying cylinder 3, and a hot air inlet is provided on the side wall of the mixing chamber 31, and the The hot air inlet is connected with a tangential air inlet channel 2 that tangentially enters the drying cylinder 3, and the front end of the tangential air inlet channel 2 is connected with the hot air mechanism that provides hot air to the drying cylinder 3;

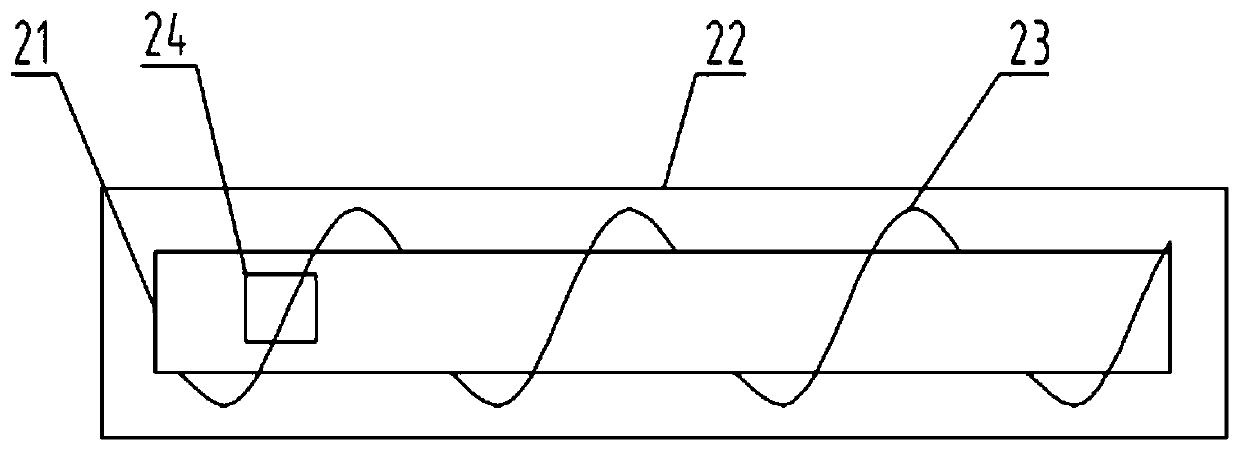

[0031] In the stirring chamber 31, there is an agitator that stirs up the silicon carbide powder so that it is blown up by the rotating hot air formed from the tangential air inlet passage 2, and in the drying drum 3 above the stirring chamber 31, there is a The powder material ascending channel 4 communicated with the mixing chamber 31 is provided with a wet material feed port at the joint between the powder material ascending channel 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com