DMDO crystal decolorizing and drying device

A drying device and crystallization technology, applied in the direction of drying gas arrangement, crystallization separation, heating device, etc., can solve the problems of solution pollution, trouble, and ineffective dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

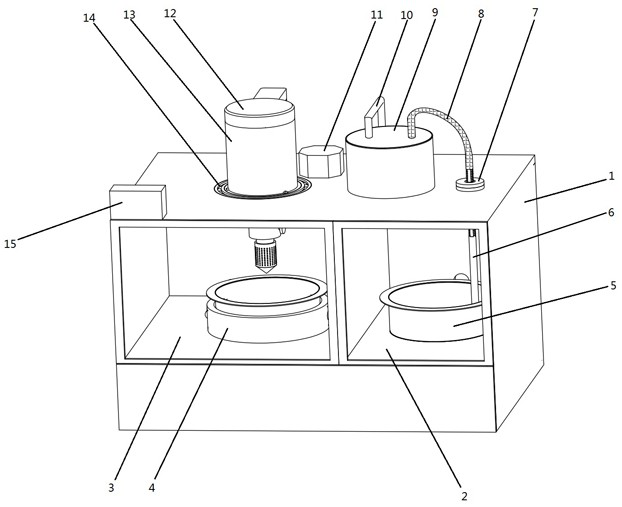

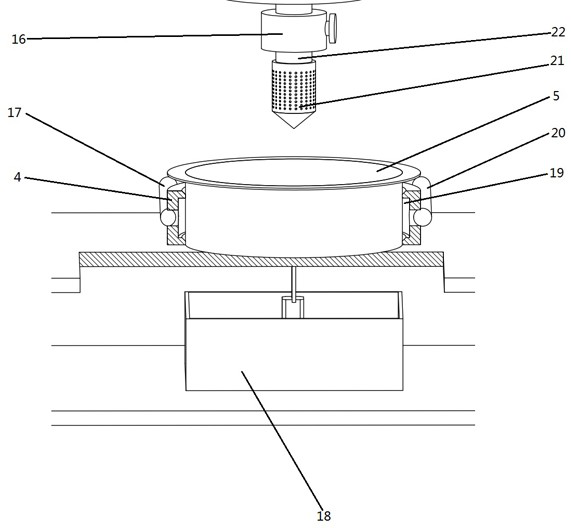

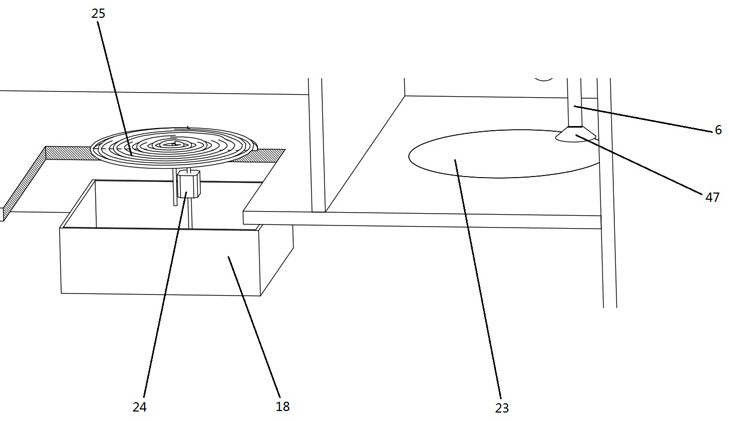

[0033] Example 1, such as figure 1 Shown in -11, the DMDO crystal decolorization and drying device includes casing 1, glassware 5, and casing 1 is provided with controller 15, and controller 15 is preferably Mitsubishi FX2N-64MT-001 controller 15, and controller 15 is used To control the electric cylinder 34, the inner stirring motor 37, the outer stirring motor 11, the water pump 24, the vacuum pump 45, the heating rod 30 and the heating pipe 23, the box 1 is divided into a crystallization area 3, a drying area 2, a crystallization area 3, and a drying area 2. The box body 1 on the front side is equipped with switchable transparent doors. The crystallization area 3 and the drying area 2 are in a sealed state when the transparent doors are closed, and a decolorization mechanism is installed on the left side of the top of the box body 1.

[0034] The decolorization mechanism dissolves the DMDO crystals containing impurities and filters the impurities; the decolorization mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com