Recycled plastic drying device

A technology of recycled plastic and drying oven, applied in the field of plastic product manufacturing, can solve the problems of water vapor being unable to be removed in time, melting of recycled plastic particles, and excessive internal temperature, and achieve the effect of improving heat transfer efficiency, uniform mixing, and slowing down drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

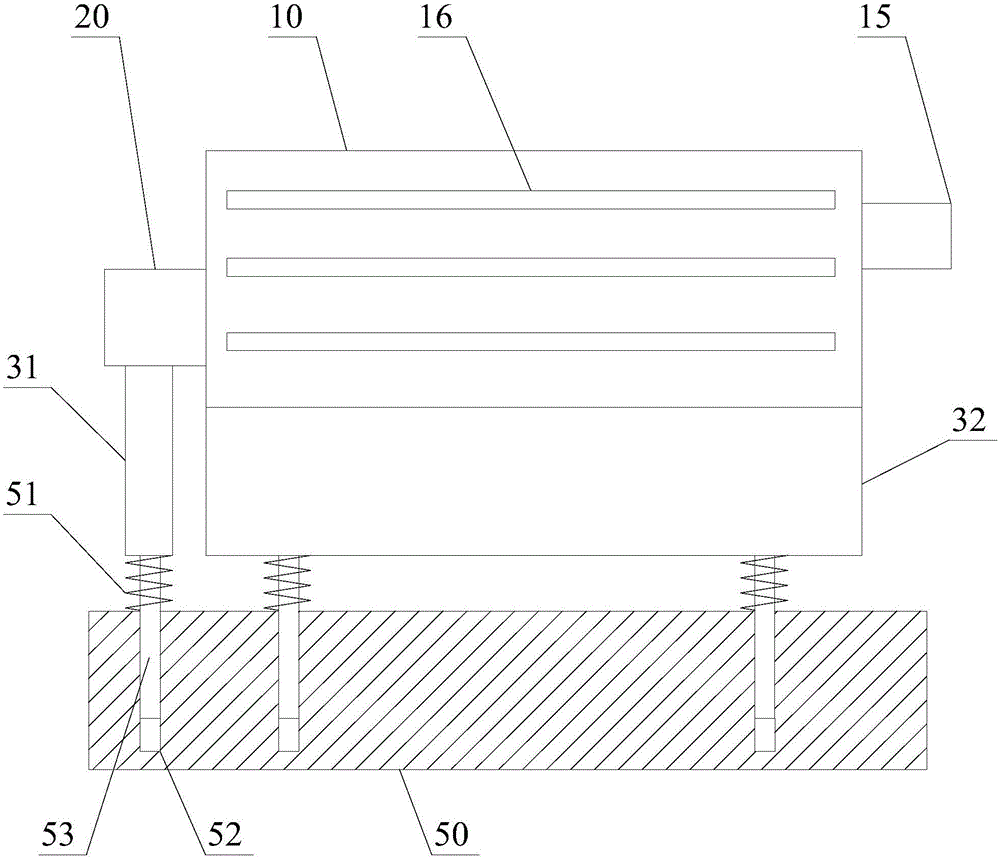

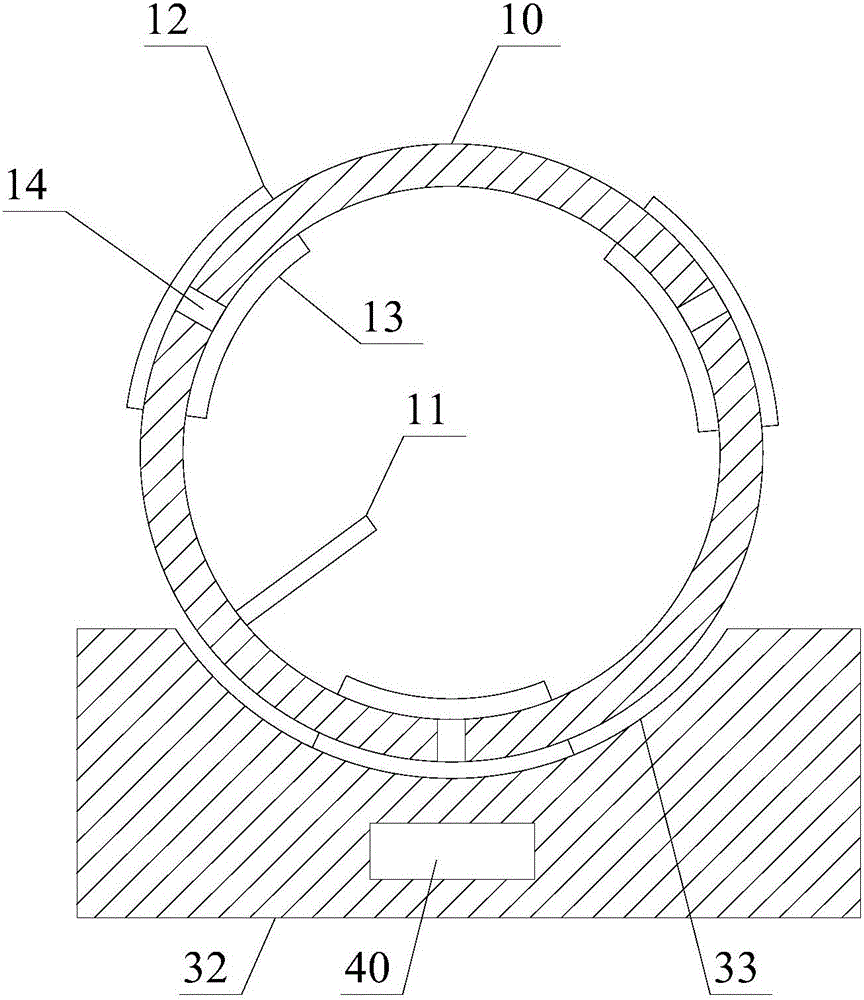

[0030] Such as figure 1 and figure 2 As shown, the recycled plastic water removal device includes a drying box 10, an outer heat conducting sheet 12, an inner heat conducting sheet 13, a heat conducting column 14, a drive motor 20, a motor support 31, a drying oven support 32, and an electric heater 40;

[0031] The drying box 10 is a hollow cylindrical structure; the driving motor 20 is centrally connected with one end of the drying box 10; the opposite end of the drying box 10 is provided with a material port 15; The outer peripheral surface is densely covered with strip-shaped ventilation holes 16; the outer heat conduction sheet 12 is arc-shaped, and a plurality of the outer heat conduction sheets 12 are fixed on the outer peripheral surface of the drying box 10; the outer heat conduction sheet 12 is formed from the One end of the drying box 10 extends to the other end; there is a space between the adjacent heat conducting sheets 12; the inner heat conducting sheets 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com