Submerged nozzle for sheet billet continuous casting crystallizer

A technology of thin slab continuous casting and crystallizer, which is applied in the direction of casting melt container, casting equipment, manufacturing tools, etc. It can solve the problems such as the outlet angle and flow speed are not ideal, so as to achieve uniform distribution of mold slag and prevent slag entrainment , the effect of reasonable liquid surface velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

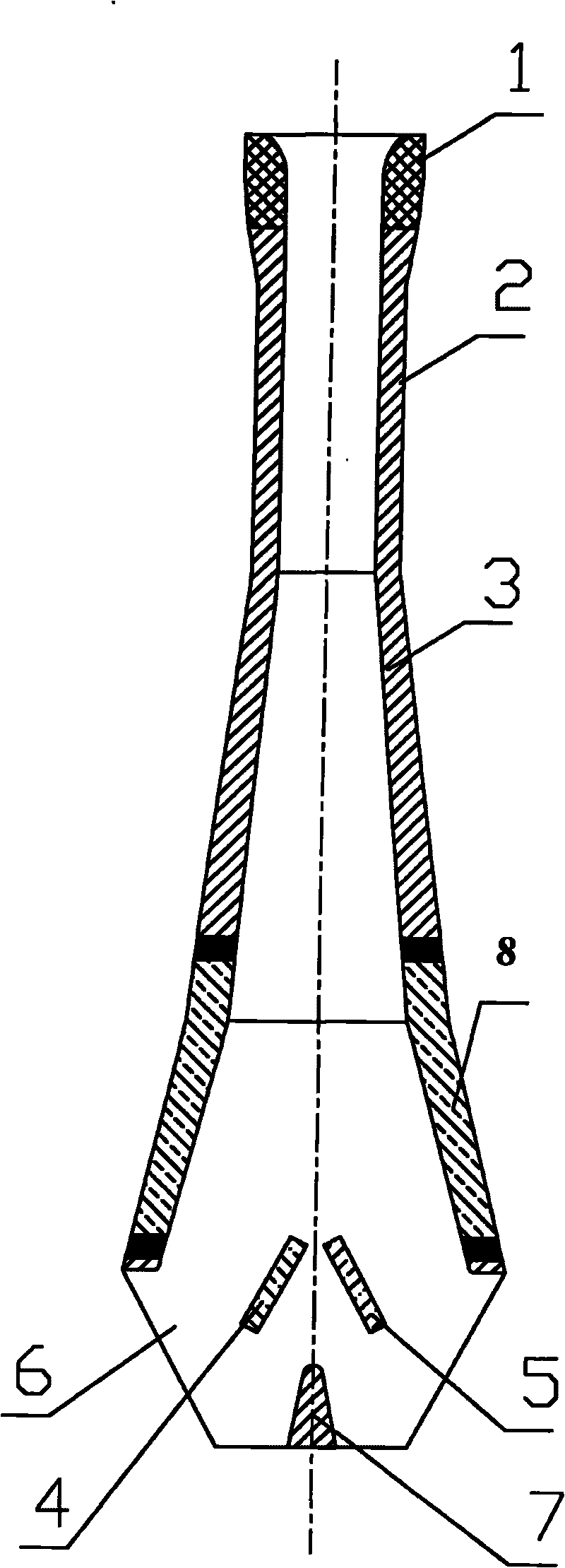

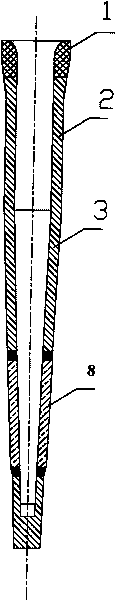

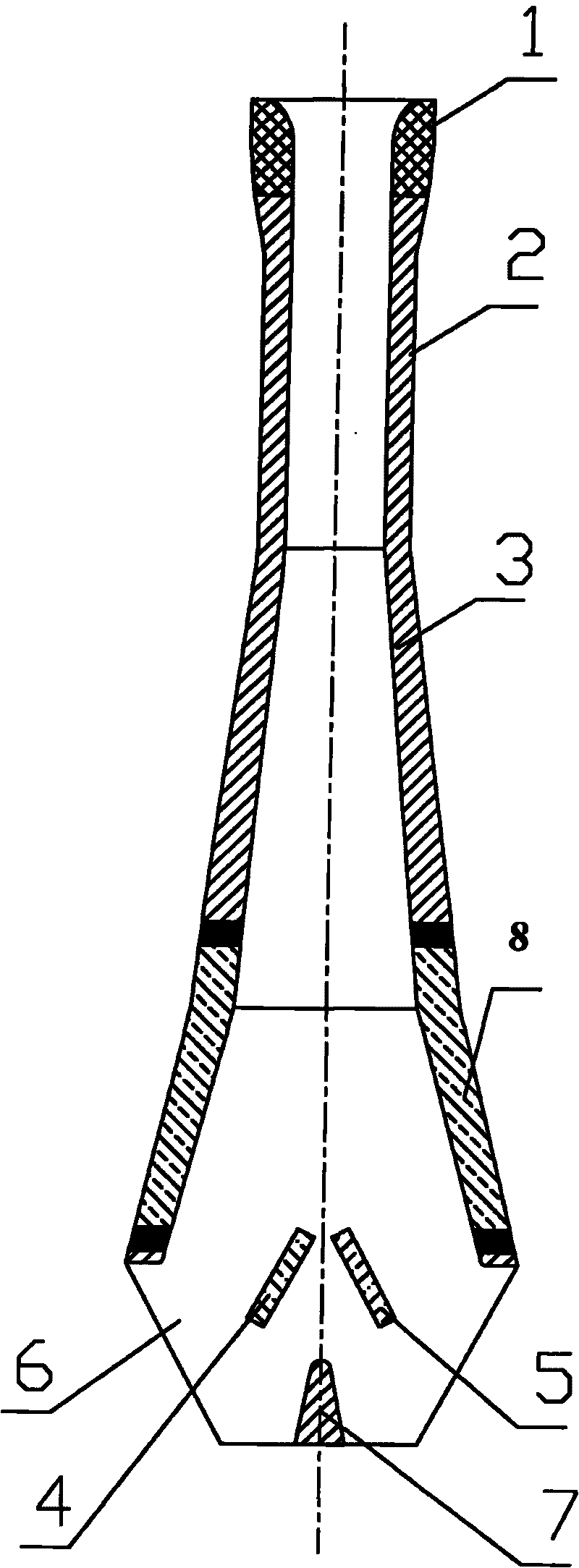

[0015] Such as figure 1 , 2 Among them, the submerged nozzle for the thin slab continuous casting crystallizer of the present invention mainly includes an upper end 1, a transition section 2, an upper flat section 3, a nozzle outlet 6 and a lower flat section 8, the upper end 1 is in the uppermost section and is in the shape of a conical funnel, and the transition section 2 is connected below the upper end 1, the transition section 2 is cylindrical and has a cross-sectional shape, the upper flat section 3 is below the transition section 2, the lower flat section 8 is below the upper flat section 3, the upper flat section 3 and the lower flat section 8 All are flat flat sections with two-way changes in the internal cross-sectional area of the nozzle. The cross-sectional area gradually shrinks and the longitudinal cross-sectional area gradually expands. The degree of contraction of the cross-sectional area of the upper flat section 3 and the degree of expansion of the longit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com