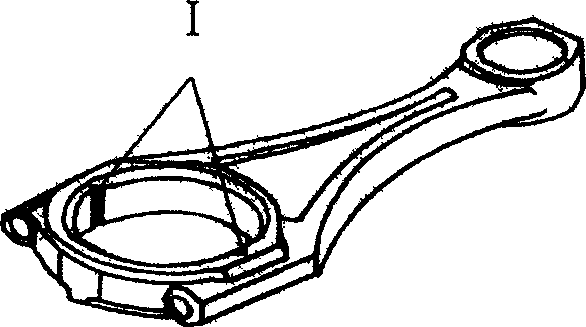

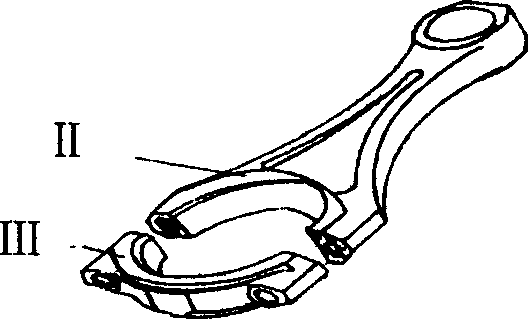

Processing apparatus for initial cracking tank for engine connecting rod

A technology for engine connecting rods and processing devices, which can be applied to broaching devices, metal processing equipment, manufacturing tools, etc. It can solve the problems of difficult stability of processing quality and difficult adjustment of laser system, so as to avoid slag falling on the fracture surface and high dimensional accuracy , the effect of improving the quality of the fracture surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

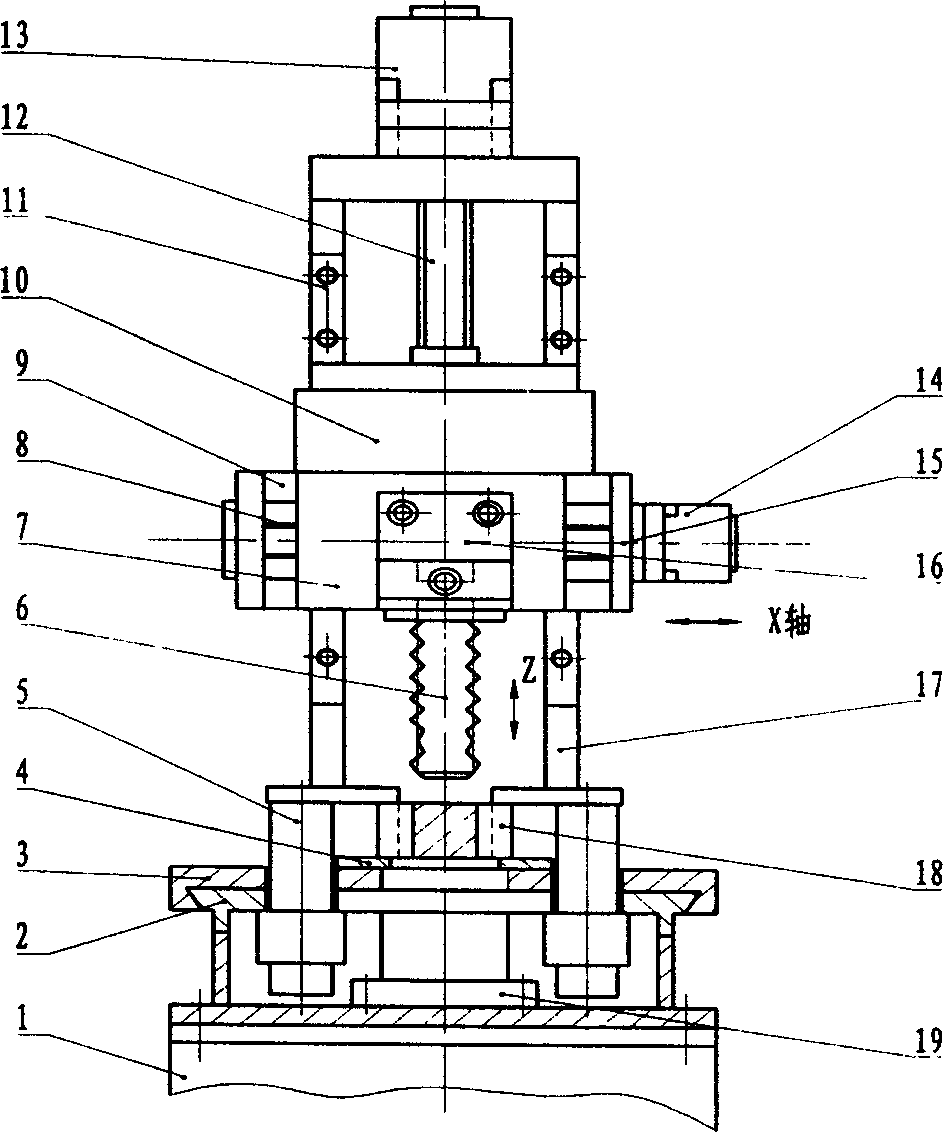

[0031] The following examples in conjunction with the accompanying drawings will further illustrate the equipment of the present invention:

[0032] Refer to attached image 3 , attached Figure 4 , a device for machining initial cracking grooves of connecting rods, including a main machine and a workbench. The main frame is composed as follows: a main frame 17 is arranged above the frame-type frame base 1, and a z-axis slide block 10 that moves up and down along the z-axis guide rails 11 on both sides is arranged in the z-axis direction of the frame. The z-axis slide block 10 is provided with an x-axis guide rail seat 15, and the x-axis slide block 7 equipped with a broach fixing seat 16 moves horizontally in the x-axis direction on the guide rail 9.

[0033] The workpiece clamping and positioning workbench is composed as follows: the workbench is fixed on the frame base 1, the y-axis slider 3 moves linearly in the y-axis direction along the y-axis guide rail 2, and the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com