Online detecting, soot blowing and optimal energy-saving method for large coal-fired boiler

A coal-fired boiler, a large-scale technology, applied in the direction of radiation pyrometry, boiler working status indication, measuring device, etc., can solve the problem of lack of online detection of supercritical boiler heating surface cleaning, inability to accurately calculate the heat transfer characteristics of the heating surface, difficult Achieve optimization of soot blowing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

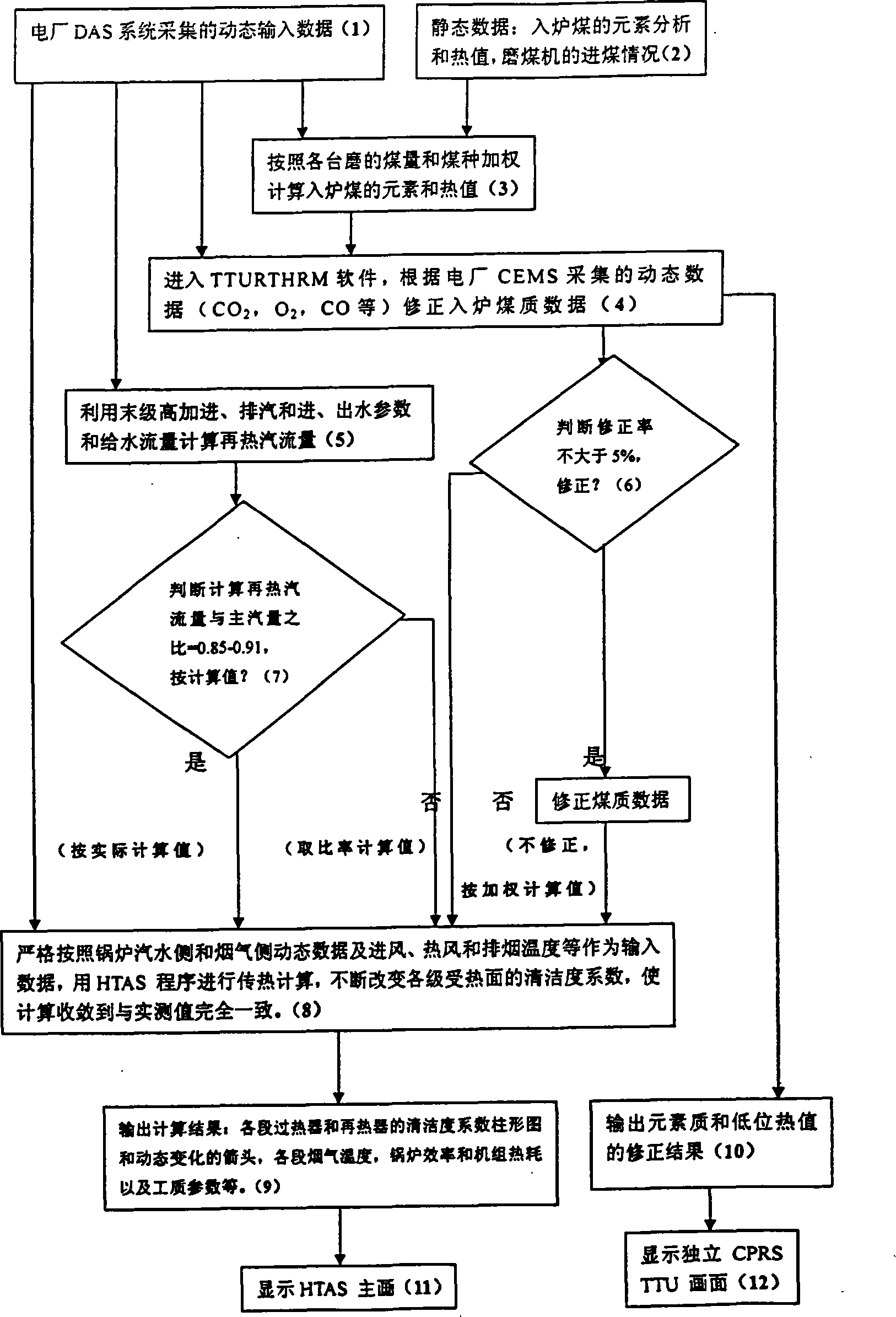

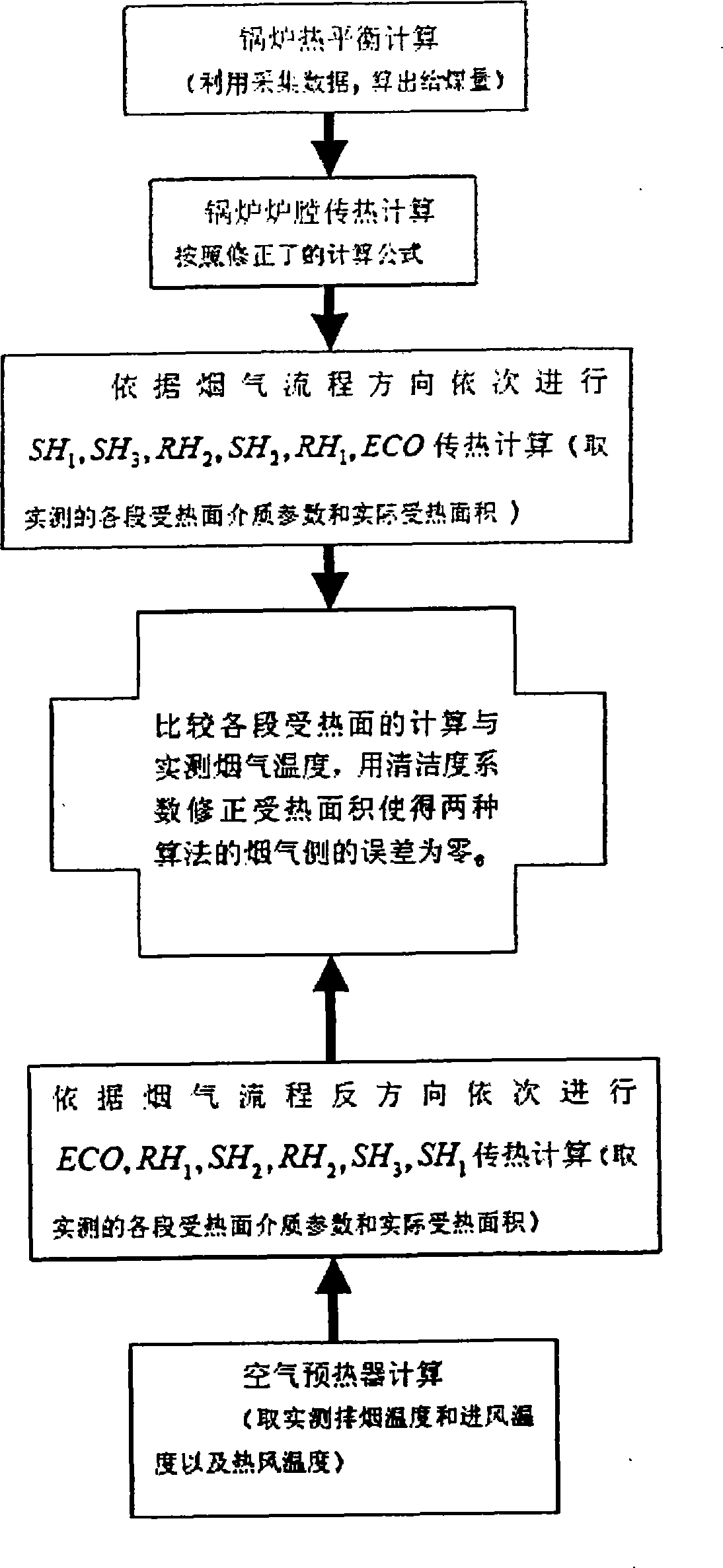

[0114] As shown in Figure 1, it is a program flow chart of a large-scale coal-fired boiler on-line detection, soot blowing optimization and energy-saving method. When the present invention is applied to the first 900MW supercritical boiler, the data used in this system are all taken from Waigao The pi database of Qiao No. 2 Power Plant is collected as follows:

[0115] The first step. Use the power plant DAS system to collect boiler dynamic data

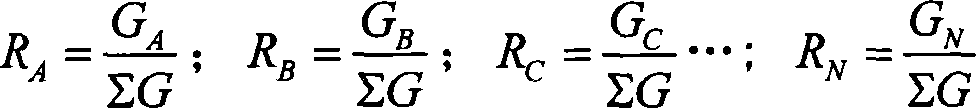

[0116] a) The power plant provides the collection of dynamic online data required for system calculation. According to the corresponding kks number, provide the user name and password of the pi system under the ip connection parameters to obtain: main and reheat steam flow and outlet pressure, temperature and superheaters of each section, Reheater and economizer heating surface inlet and outlet medium pressure, temperature, feed water flow; cold air temperature, air preheater inlet air temperature, secondary hot air temperature, exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com